Numerical control stretch bending machine tool and clamping force monitoring method of round head fixture thereof

A technology of clamping force and round head clamp, which is applied in the field of CNC machine tools, can solve the problems of workpiece clamping, high energy consumption, and heavy clamping marks of the workpiece, and achieve the effects of protecting the workpiece, saving energy, and avoiding excessive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

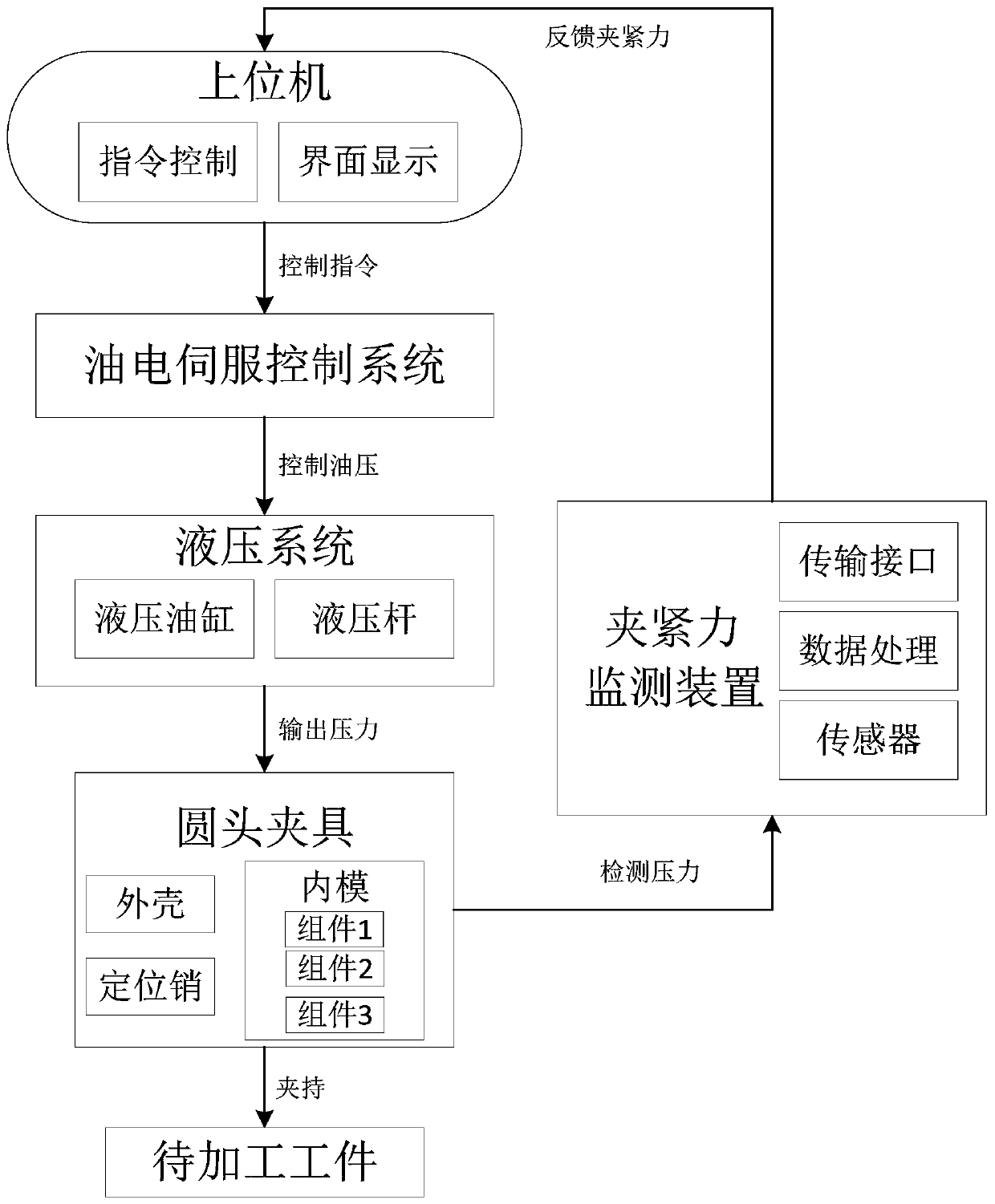

[0055] see figure 1 as well as figure 2 , this embodiment provides a numerically controlled stretch bending machine tool, which includes a round head fixture, a hydraulic system, and a clamping force monitoring device, and may also include a host computer and a hybrid electric servo control system. The CNC stretch bending machine is used to stretch and bend workpieces, such as stretch bending various steel pipes, square pipes, H-beams, I-beams, channel steels, angle irons, flat irons and aluminum profiles.

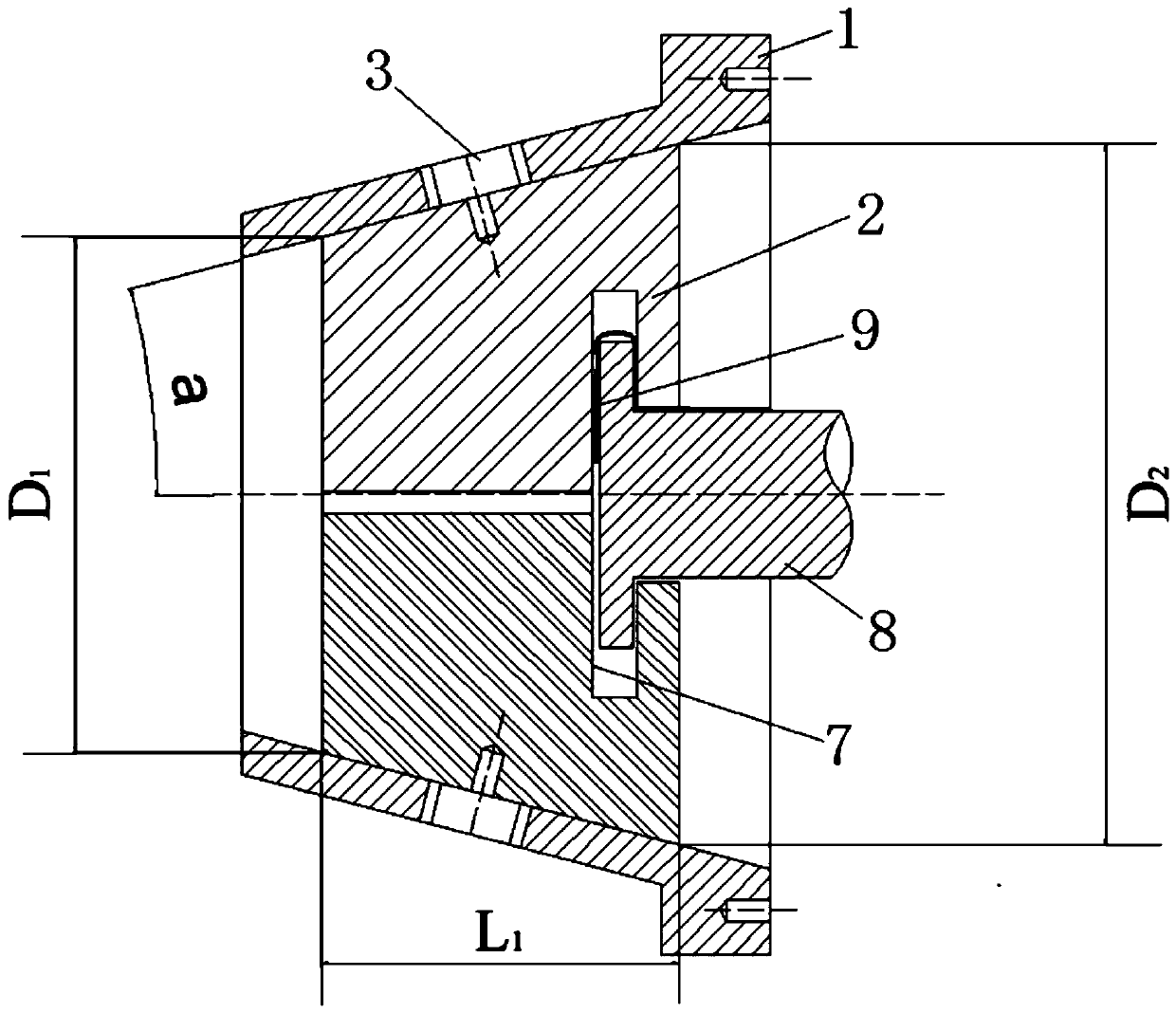

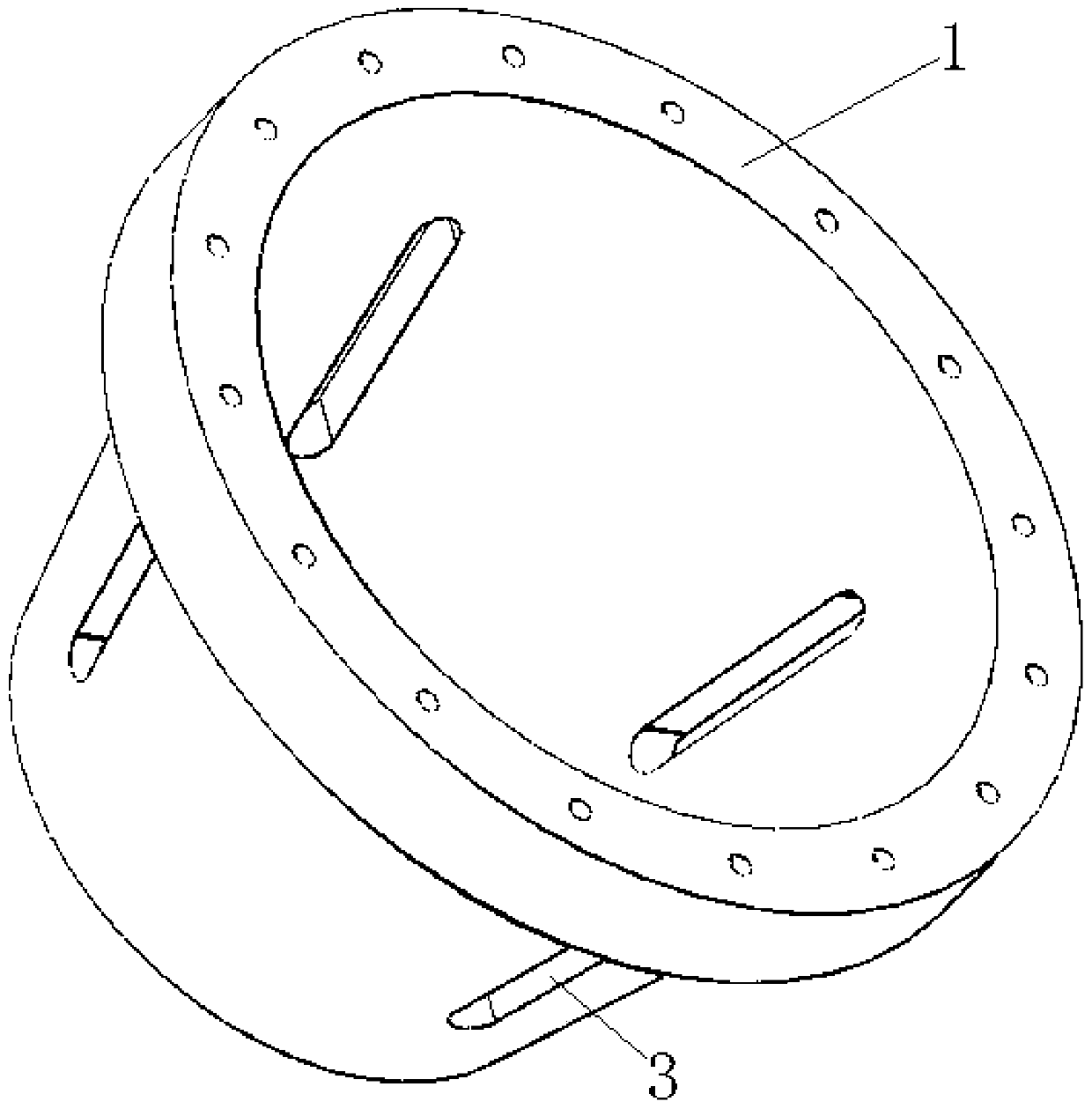

[0056] The round head clamp is used to clamp the workpiece and can be installed on other fixed structures of the CNC stretch bending machine. The round head clamp includes a shell 1, an inner mold 2 and a positioning member. The inner mold 2 is arranged in the shell 1. The positioning piece is used to position the inner mold 2 in the shell 1, and preferably a positioning pin. Such as image 3 As shown, the outer contour of the shell 1 is in the shape of a truncated con...

Embodiment 2

[0077] read on figure 2 , this embodiment provides a clamping force monitoring device for a round-head fixture, which is independent from the numerically controlled stretch bending machine tool of Embodiment 1 and applied to the numerically controlled stretch bending machine tool. What needs to be explained here is that when applying the clamping force monitoring device of the round end fixture in this embodiment, the CNC stretch bending machine tool may not include the clamping force monitoring device, that is, the clamping force monitoring device of the round end fixture shall be regarded as an independent product It can also be used in other CNC stretch bending machine tools. Wherein, the clamping force monitoring device of the round head fixture includes a detection mechanism, a cone angle calculation unit and a clamping force calculation unit.

[0078] The detection mechanism is set in the installation groove 7 and is used to detect the pressure F between the hydraulic ...

Embodiment 3

[0081] This embodiment provides a method for monitoring the clamping force of a round head fixture, which is applied to the numerically controlled stretch bending machine tool in Embodiment 1, and includes the following steps:

[0082] 1. Detect the pressure F between the hydraulic rod 8 and the inner mold 2 0 ;

[0083] 2. Calculate the cone angle α of the conical structure, and the calculation formula is α=tan -1 [D 2 -D 1 / 2*L 1 ]; where D 1 is the radius of the top surface of the cone structure, D 2 is the radius of the bottom surface of the cone structure, L 1 is the height of the frustum structure;

[0084] 3. Calculate the clamping force F between the inner mold 2 and the workpiece 3 , and the calculation formula is F 3 =F 0 * cot α.

[0085] The effect of the method for monitoring the clamping force of the round end fixture provided in this embodiment is the same as that of the device for monitoring the clamping force of the round end fixture in Embodiment 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com