Vacuum adsorption platform

A technology of vacuum adsorption platform and empty pipe fittings, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inconvenient processing, affecting the adsorption effect of vacuum adsorption platform, and the inability of independent chamber air to be evacuated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

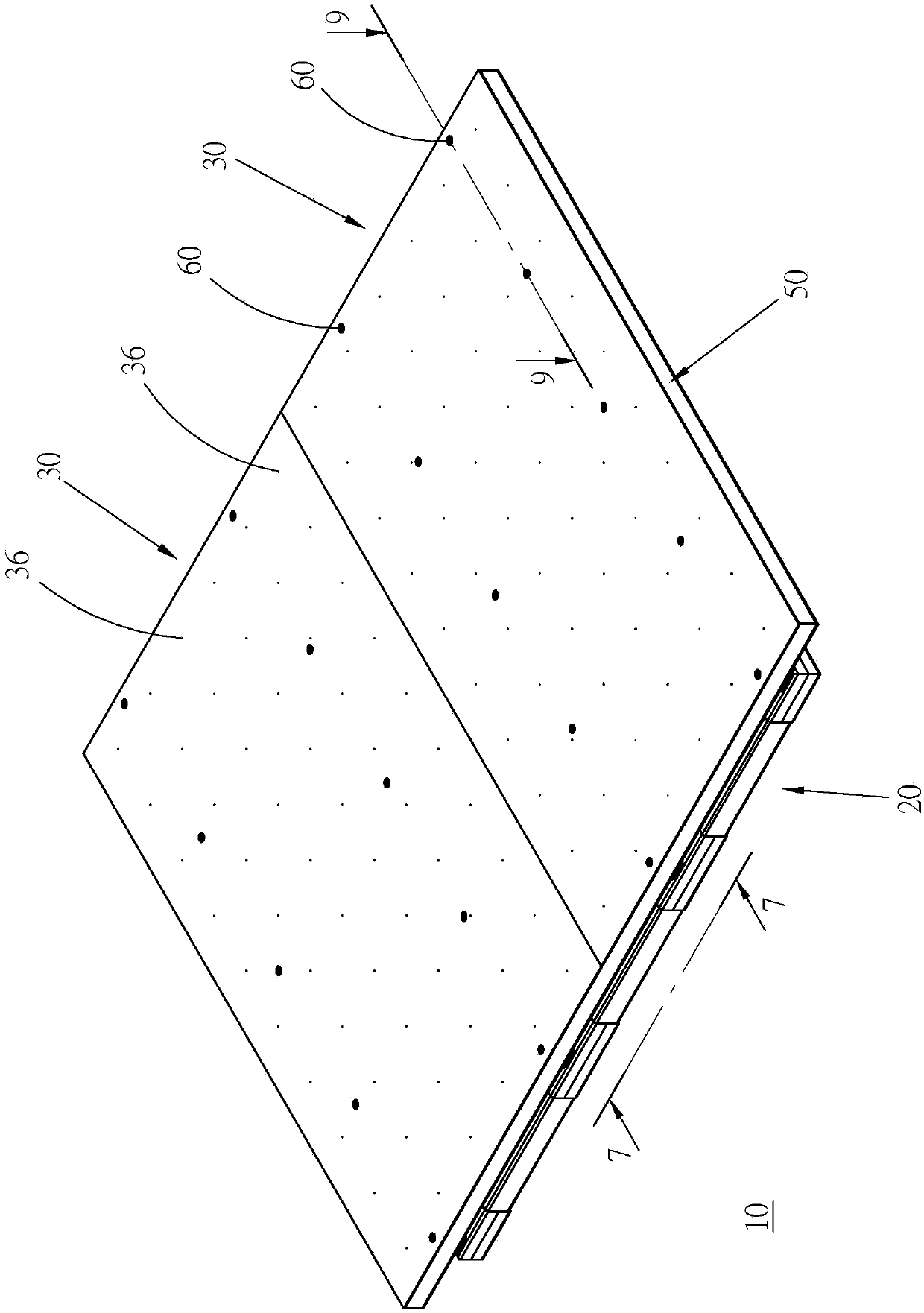

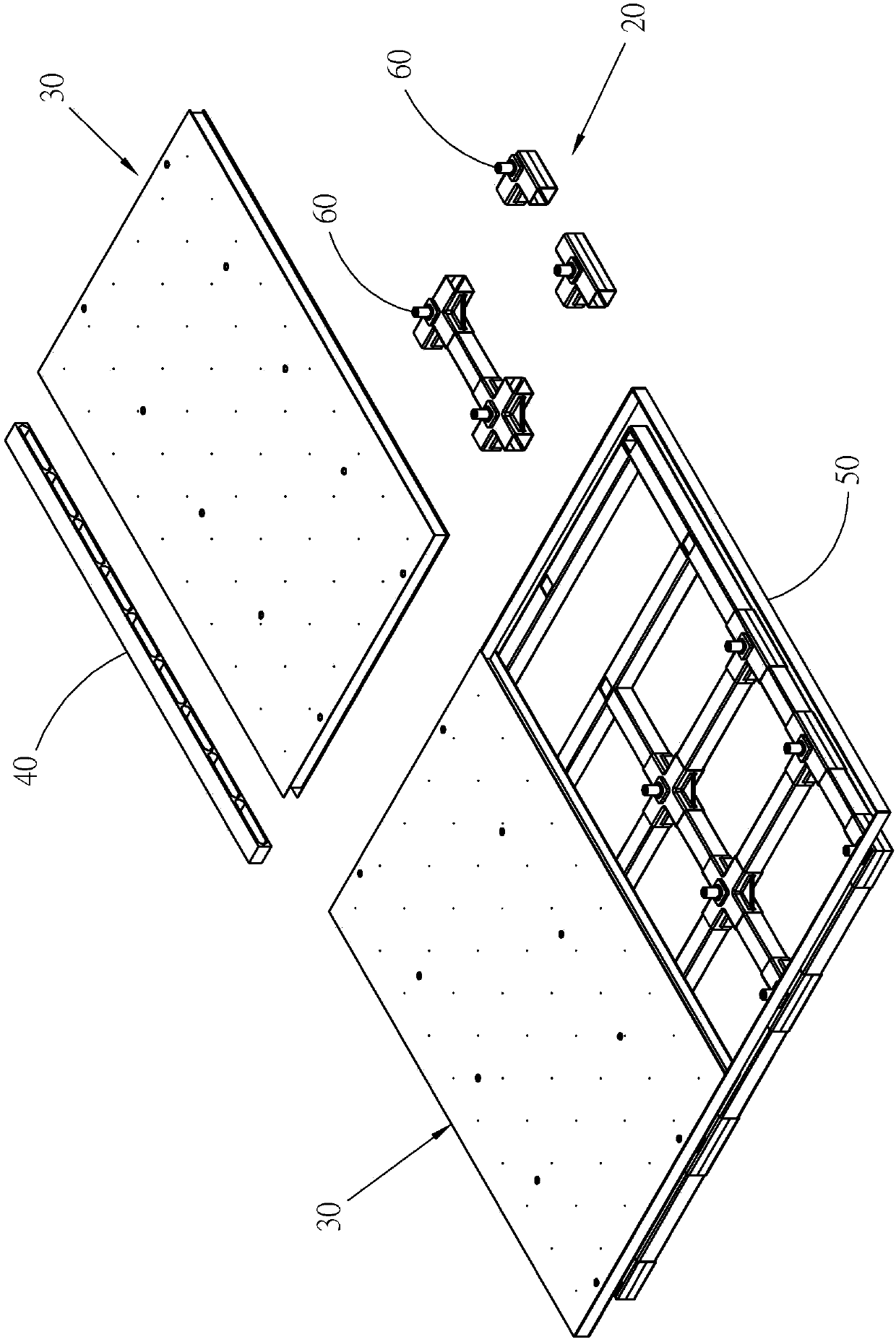

[0039] First, see figure 2 and image 3 As shown, the vacuum adsorption platform 10 provided in a preferred embodiment of the present invention mainly includes a base 20, two table parts 30, a connecting part 40, a frame part 50 and a plurality of adjusting parts 60, wherein The connecting piece 40 is interposed between the table pieces 30 , and is framed by the frame portion 50 around the entire peripheral side of each table piece, and each adjustment piece 60 is bridged between the base 20 and each table piece 30 .

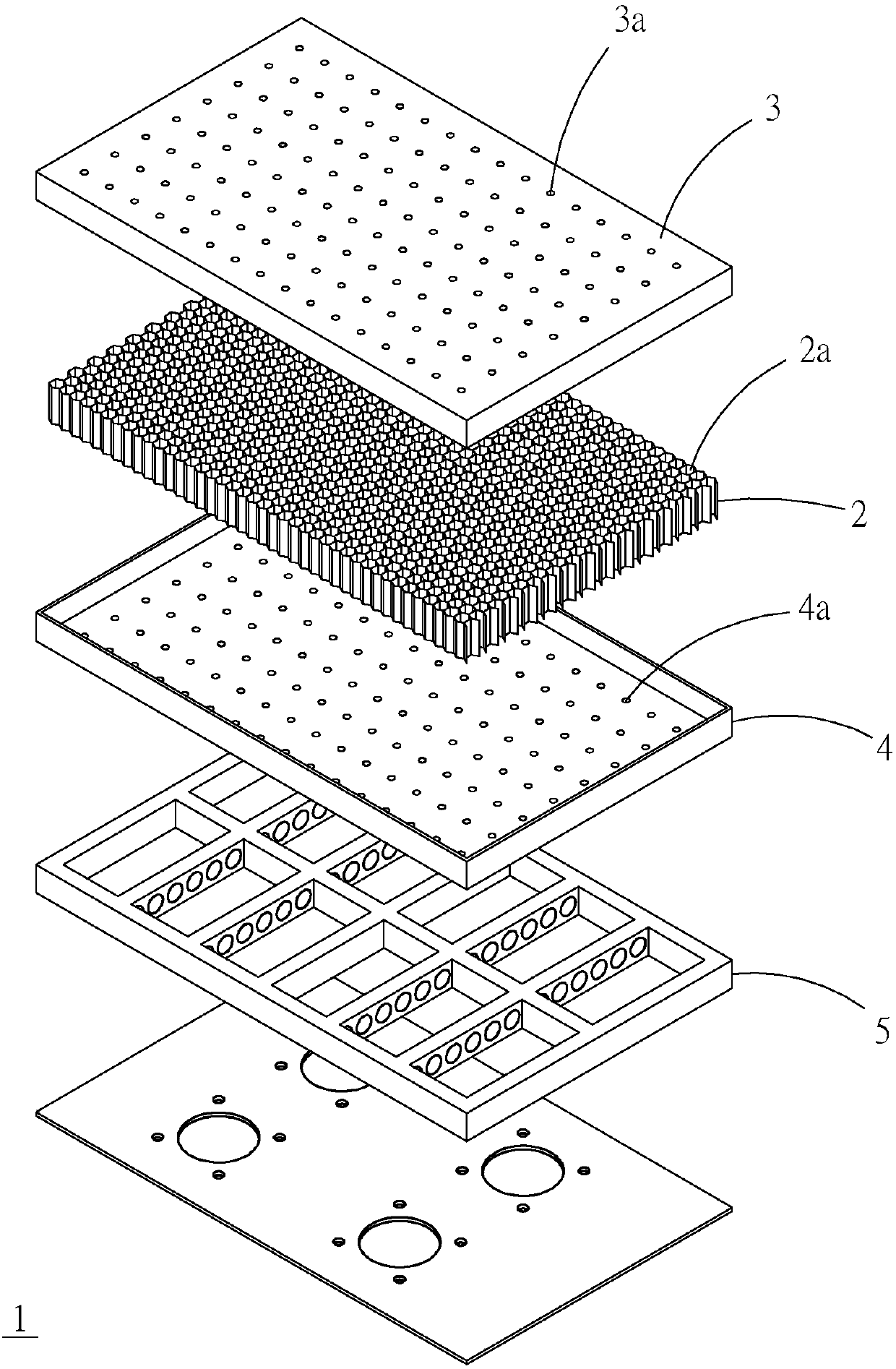

[0040] like Figure 4 and Figure 9 As shown, the base 20 has a plurality of hollow pipes 21, a plurality of reinforcements 22, and a foam core 23; wherein, the cross-sections of the hollow pipes 21 are quadrangular, intersect each other and overlap each other to form a grid shape, Each reinforcing member 22 has a shape similar to that of each hollow pipe member 21 cross-overlapped, and is a hollow formed by butting a half-shell-shaped first accommodating po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com