Press tonnage measuring method

A measurement method and press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor quality of stamping products, high purchase cost, and inability to clearly know the striking force, so as to reduce equipment configuration costs and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

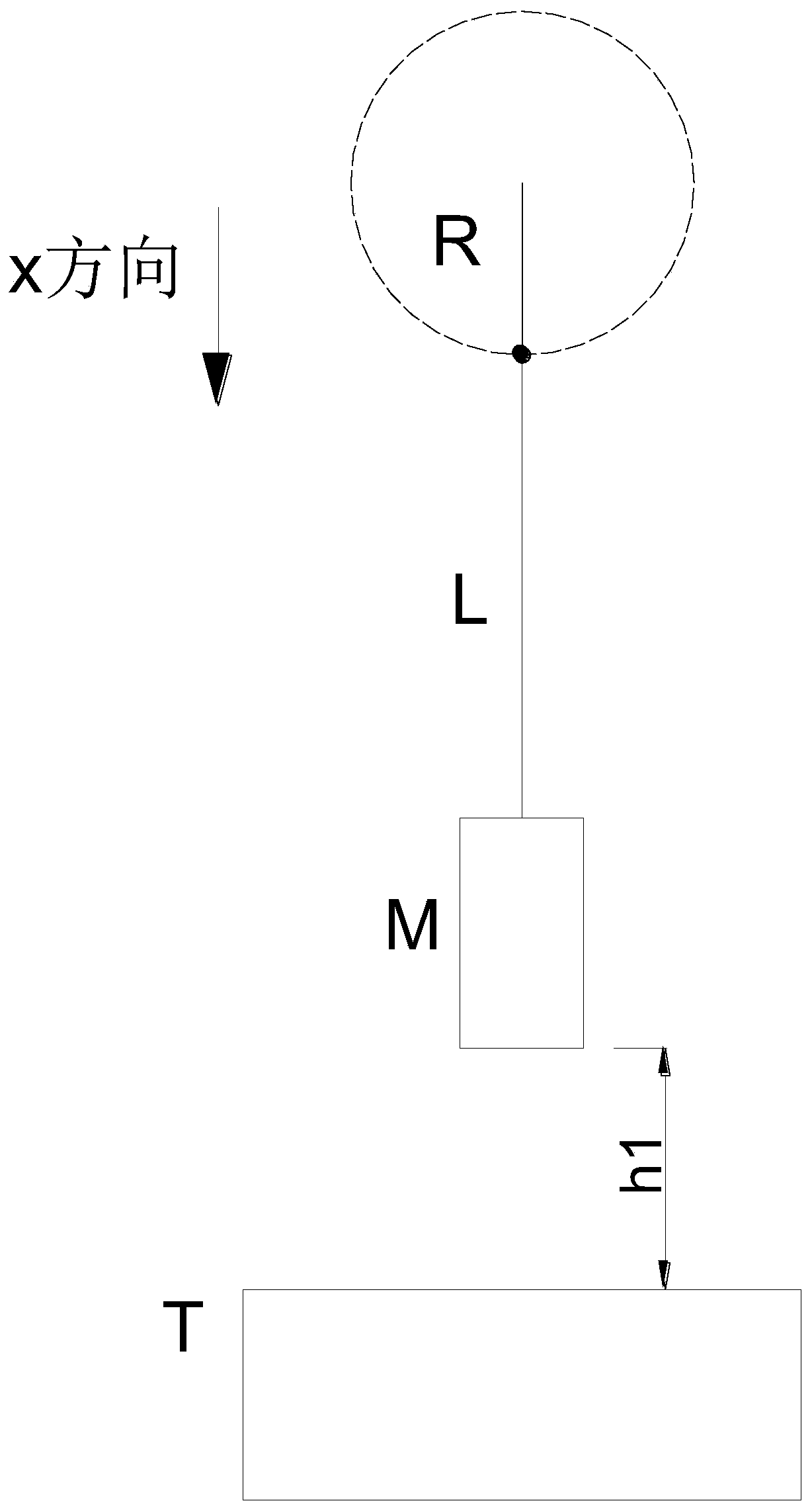

[0041] The measurement method of the present embodiment comprises the following steps:

[0042] a. Connect the acceleration sensor to the signal input terminal of the MCU microcontroller unit of the modulus display device;

[0043] b. Install the mold height indicator provided with the acceleration sensor in step a on the slide block of the press;

[0044] c. the acceleration sensor described in the step b senses the acceleration signal of the press slider, and transmits the acceleration signal to the MCU microcontroller unit of the mold height display;

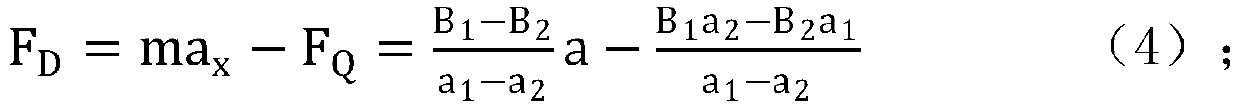

[0045] d. the MCU microcontroller unit described in step c calculates the actual impact force of the press in the course of work according to the input acceleration signal;

[0046] e. The MCU micro-controller unit described in step d displays the calculated strike force data on the display unit in real time.

[0047]The present embodiment comprises mold height display device, and mold height display device is provided with...

Embodiment 2

[0074] On the basis of Embodiment 1, the striking force data display unit of this embodiment may also be the display screen of the press console, and the MCU microcontroller unit transmits the striking force data to the press console through the communication interface unit. That is to say, the impact force data can be displayed through the display unit of the electronic mold height display to display the mold height, or through the display screen of the press console, and the two can be displayed separately or at the same time.

Embodiment 3

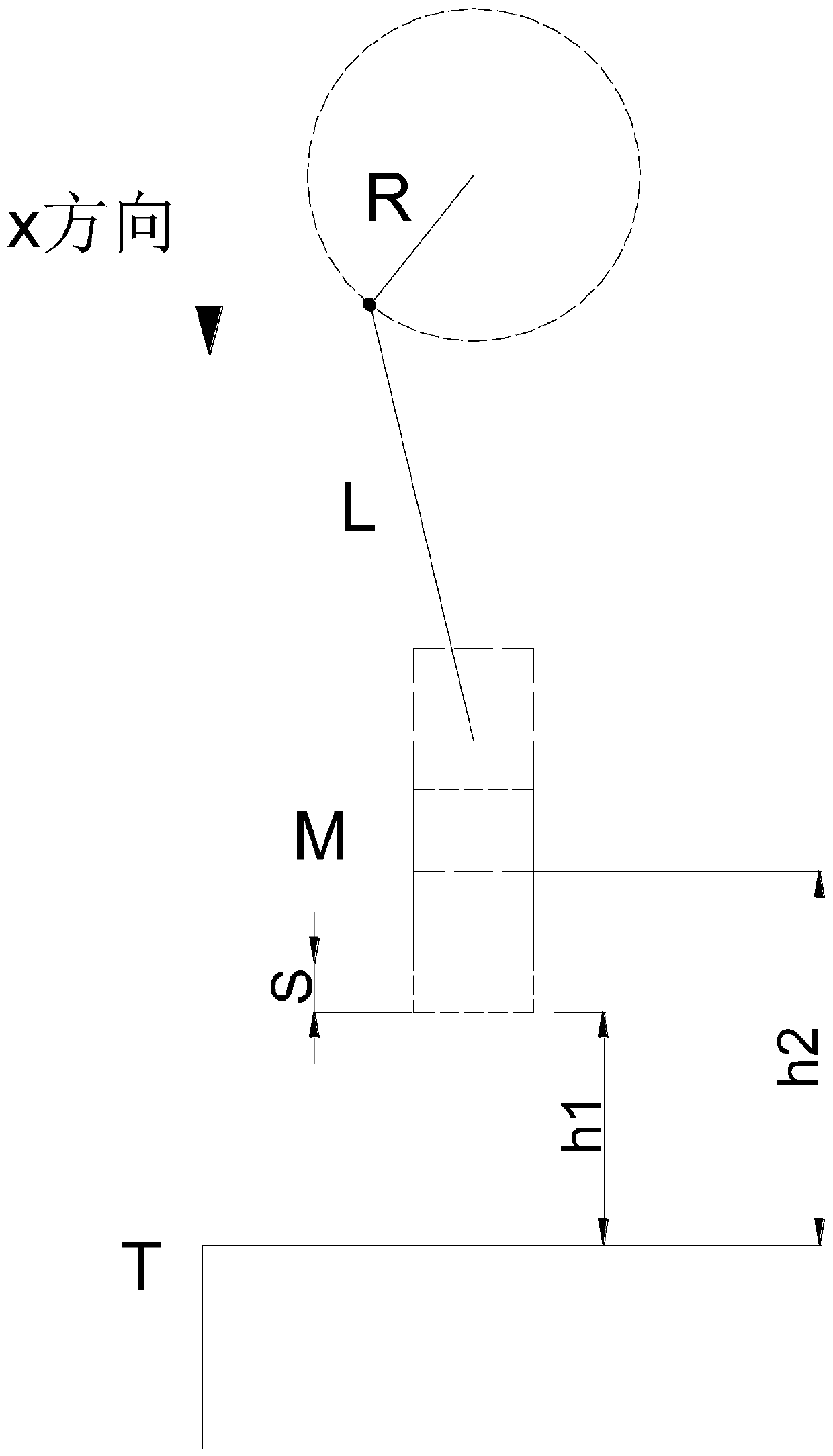

[0076] The measurement method of the present embodiment comprises the following steps:

[0077] a. Connect the acceleration sensor to the signal input terminal of the MCU microcontroller unit of the modulus display device;

[0078] b. Install the mold height indicator provided with the acceleration sensor in step a on the slide block of the press;

[0079] c. the acceleration sensor described in the step b senses the acceleration signal of the press slider, and transmits the acceleration signal to the MCU microcontroller unit of the mold height display;

[0080] d. the MCU microcontroller unit described in step c calculates the actual impact force of the press in the course of work according to the input acceleration signal;

[0081] e. The MCU micro-controller unit described in step d displays the calculated strike force data on the display unit in real time.

[0082]The present embodiment comprises mold height display device, and mold height display device is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com