Beer bottle cap wrench capable of collecting bottle cap

A bottle cap and beer technology, which is applied in the disassembly and packaging of flange-type caps, can solve the problems of small volume of beer bottle caps and difficult to collect, and achieves the effects of convenient operation, ingenious design and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments of the accompanying drawings.

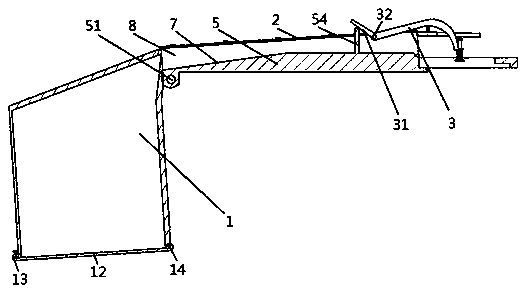

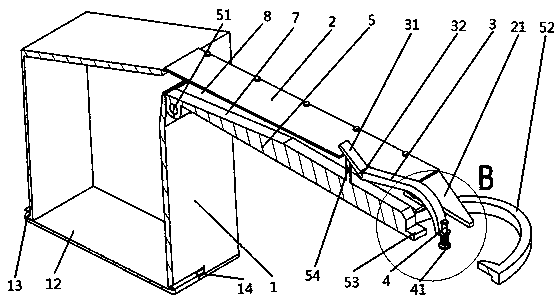

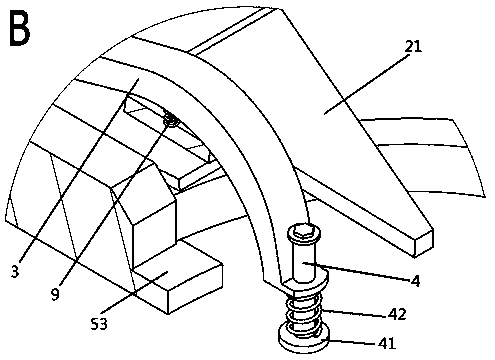

[0023] Such as Figure 1-6 As shown, a beer bottle cap wrench that can collect bottle caps according to the present invention is characterized in that: the main body is a hollow square shell 2 and a movable wrench 5, and a fixed pin is provided at the rear end of the movable wrench 5 51 is connected to the lower end of the square shell 2; the rear end of the square shell 2 is provided with a collection box 1 fixedly connected thereto, and the inside of the square shell 2 is provided with a sliding cavity 8 connected to the collection box 1; 2. The lower surface of the inner sliding cavity 8 is provided with a pressure groove 6, which is convenient for the movable wrench seat 5 to rotate and fit into the sliding cavity 8; the front end of the square shell 2 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap