Knitted fabric with pockets and knitting method with pockets

A knitted fabric and pocket technology, which is applied to the knitting field of knitted fabrics with pockets and knitted fabrics with pockets, can solve the problems of low strength, disconnection of knitting yarns, inability to join the knitted fabric parts of pockets, etc. High performance, eliminating the difference in the number of coils, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

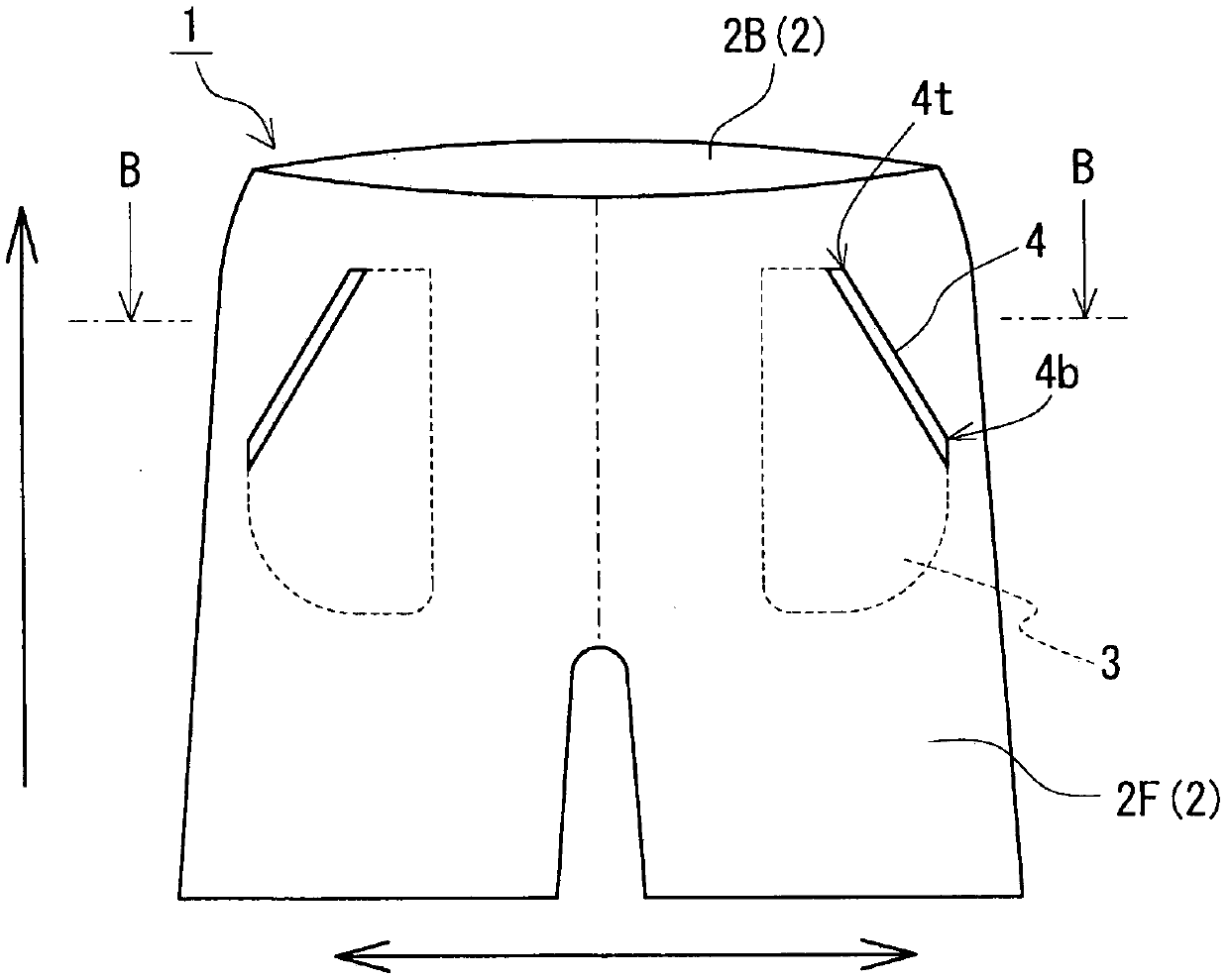

[0062] In Embodiment 1, pants 1 shown in FIGS. 1 and 2 will be described as an example of the knitted fabric with pockets of the present invention. Of course, the knitted fabric with pockets of the present invention is not limited to the trousers 1, and may be other knitted fabrics such as sweaters, knitted sweaters, and the like. In addition, the knitted fabric with pockets of the present invention may be industrial materials such as seat covers for automobiles.

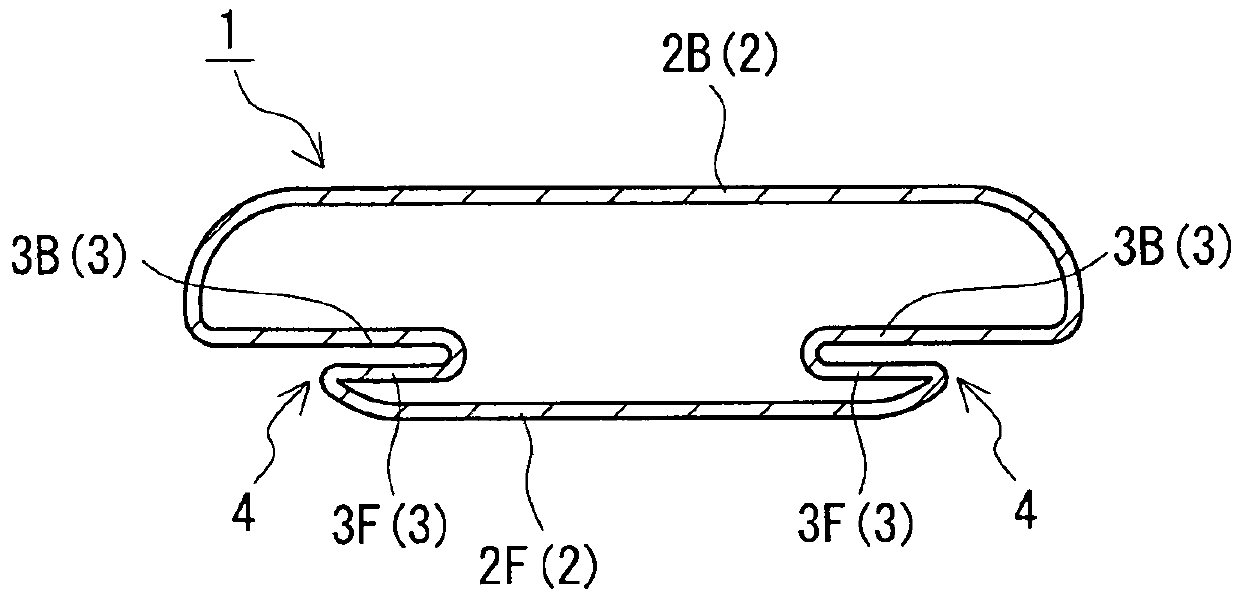

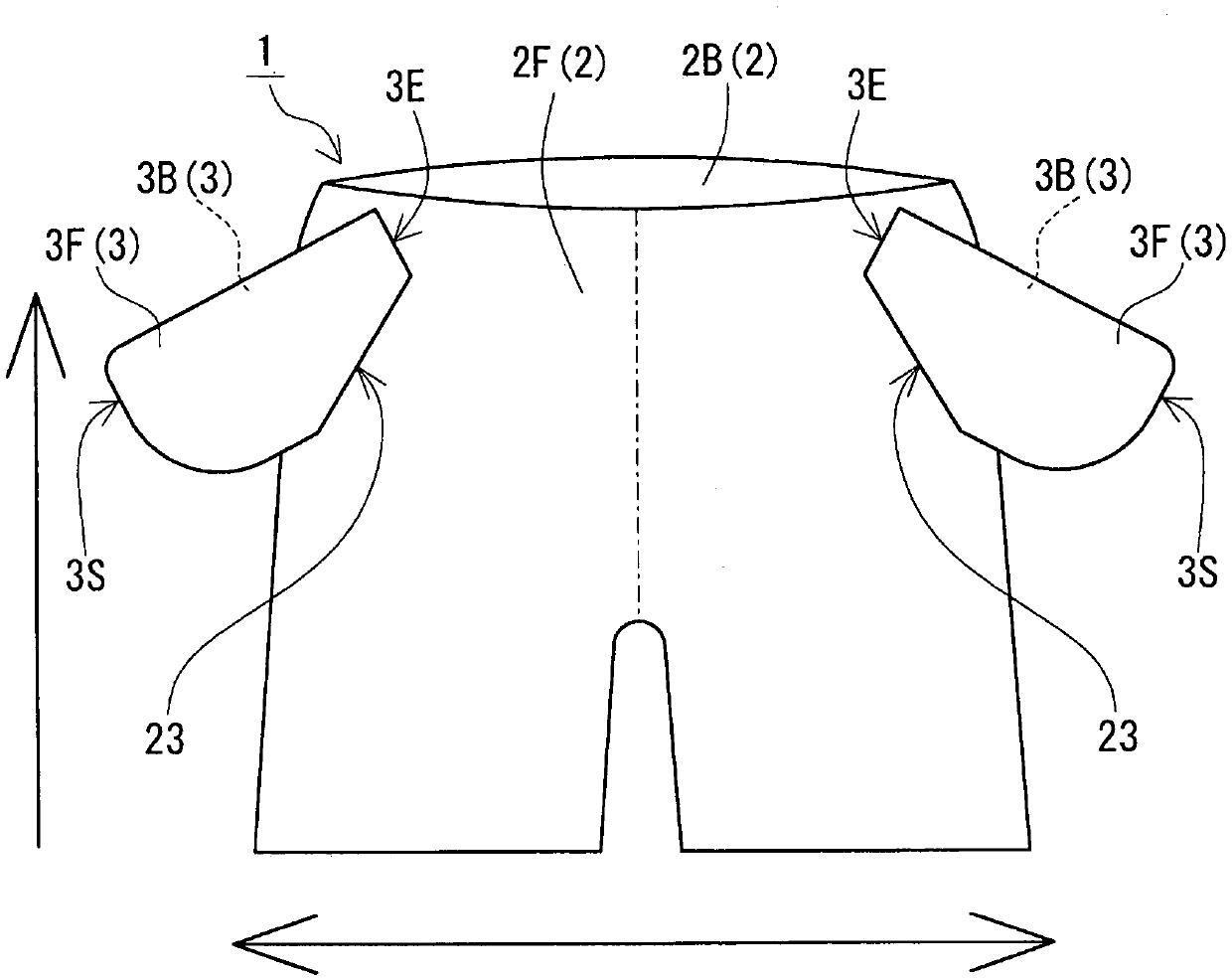

[0063] Pants 1 shown in FIG. 1 includes a tubular base knitted fabric portion 2 and a bag-shaped pocket knitted fabric portion 3 connected to the base knitted fabric portion 2 in a state disposed inside the base knitted fabric portion 2 . The base knitted fabric portion 2 is formed by connecting a front body (one base 2F) covering the front of the wearer and a back body (the other base 2B) covering the back of the wearer in a cylindrical shape. of. The base knitted fabric part 2 of this example does not have an op...

Embodiment approach 2

[0088] In Embodiment 2, an example in which all terminal portions 3E in the wale direction of the pocket knitted fabric portion 3 are joined to the base knitted fabric portion 2 will be described with reference to FIG. 7 . The viewing method of FIG. 7 is substantially the same as that of FIG. 5 . In FIG. 7 , the positions of FB and BB are indicated by dashed-two dotted lines, so that the needle beds for locking each part of the trousers 1 are clarified. In addition, black circles in FIG. 7 represent coils.

[0089] The knitting shown in FIG. 7 starts from the state in which the knitting of the boundary 23 between the one base portion 2F and the one pocket portion 3F is completed (the state in FIG. 5(A) ). In FIG. 7(A) , it is a state where one side pocket 3F is locked to FB and the other side pocket 3B is locked to BB. As already described with reference to FIG. 4 , when the one side base portion 2F is joined to the one side pocket portion 3F, a part of the other side pocket...

Embodiment approach 3

[0097] When the pocket knitted fabric portion is connected to the base knitted fabric portion that is not connected to one side of the course direction of the one base portion and the other side base portion, winding can be omitted. For example, in the case of joining the pocket knitted fabric part to one end side of the base knitted fabric part in which one end side of the base part on one side is connected to one end side in the course direction of the other base part and the other end side is not connected to the other side base part, a The side base part is moved toward the one side pocket part, and the one side base part is joined with the one side pocket part. Even if one side base part is moved to one side pocket part by transfer and traverse, the one side base part and the other side base part will not be connected at the other end side, so there will be no gap at the other end side. There is a problem of yarn breaking, so there is no need to wind in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com