On-bridge green belt construction process and bridge construction through process

A construction technology and green belt technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of low safety, increase the bearing capacity of bridges, shorten the service life of bridges, etc., to ensure driving safety, reduce self-weight, reduce The effect of cleaning workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

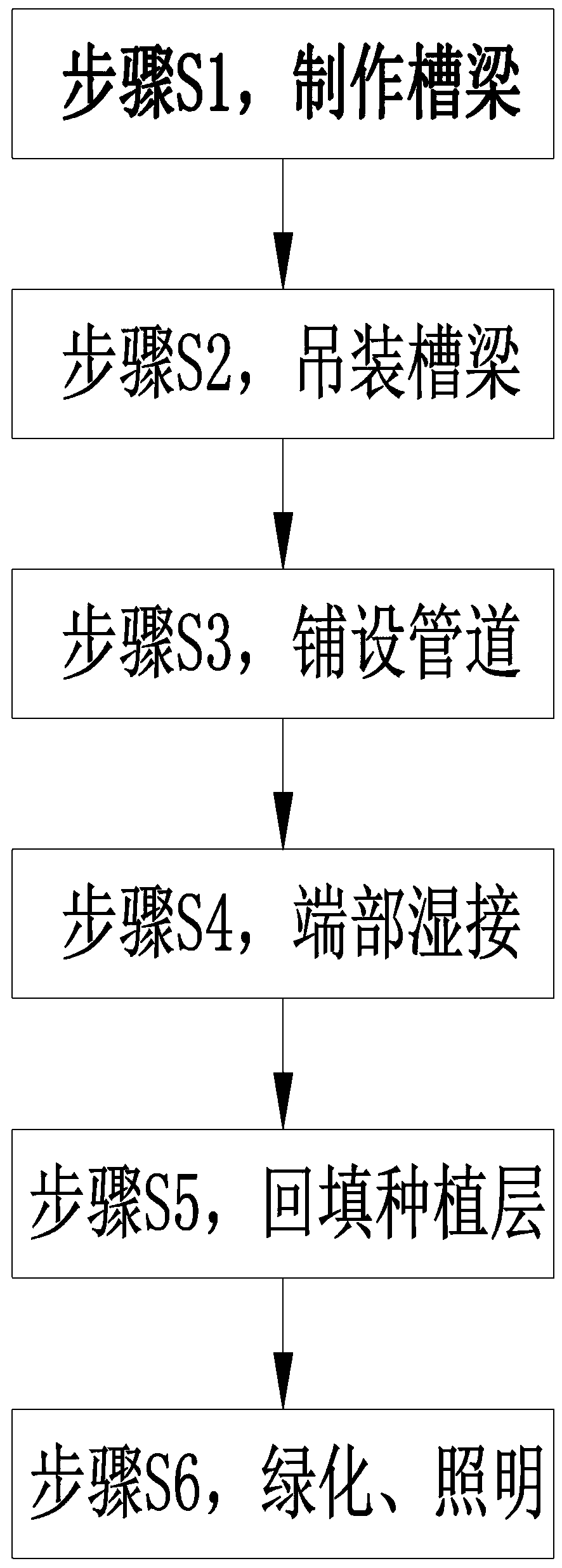

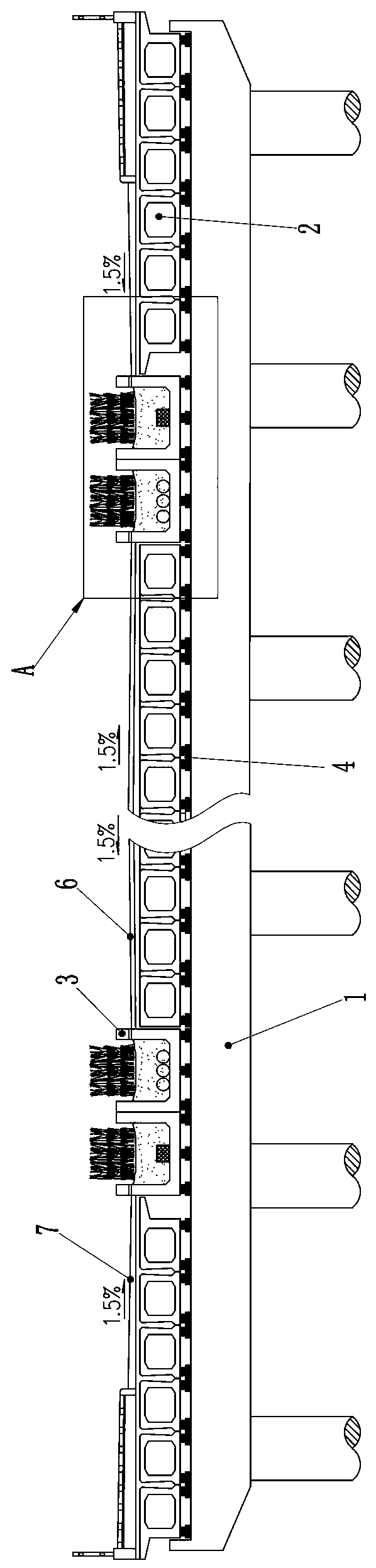

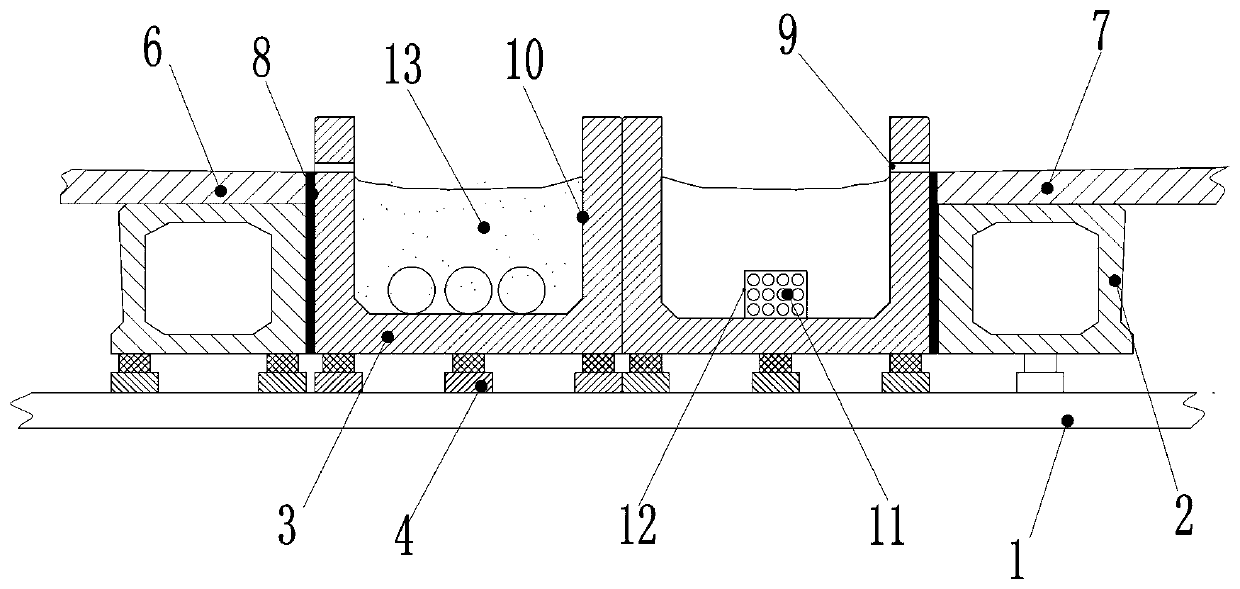

[0031] Example: such as Figure 1-Figure 6 Shown, a kind of green belt construction technology on the bridge comprises the following steps:

[0032] Step S1, making the channel beam: the U-shaped channel beam 3 is fabricated on site as a whole, and the U-shaped channel beam 3 is poured with C40 waterproof concrete, and the inside is provided with a diameter φ s 15.2mm unbonded prestressed steel strands or steel bars, the U-shaped channel beam 3 wall thickness is not less than 50mm, and the waterproof layer 10 is painted inside the U-shaped channel beam 3; the top of the U-shaped channel beam 3 is provided with a transverse beam 5 , the transverse beam 5 is used for the hoisting of the U-shaped channel beam 3, the installation of street lamps, and the improvement of the rigidity and stability of the U-shaped channel beam 3;

[0033] Step S2, hoisting the channel beam: hoist the U-shaped channel beam 3 in step S1 to the reserved position of the green belt on the bridge using li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com