Drilling cuttings amount testing device and method based on pressure sensor

A pressure sensor and testing device technology, which is applied in mining equipment, earthwork drilling, mining equipment, etc., can solve the problems of inaccurate loading and unloading of drilling cuttings, large air flow in the roadway, and long time-consuming, etc., and achieves simple structure, safety and reliability Strong, easy-to-handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

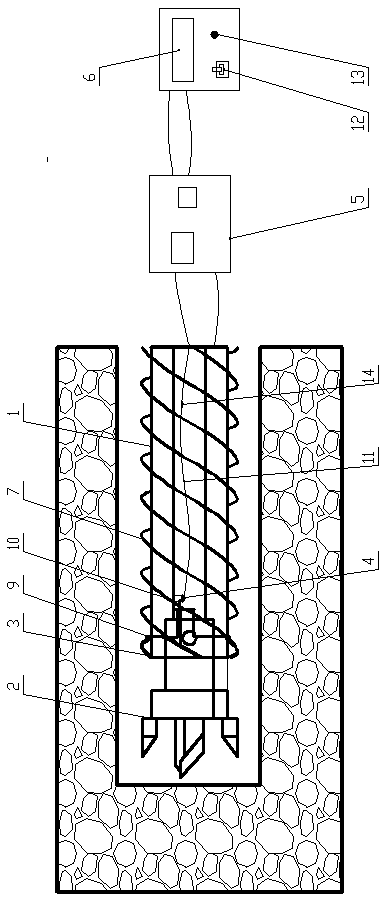

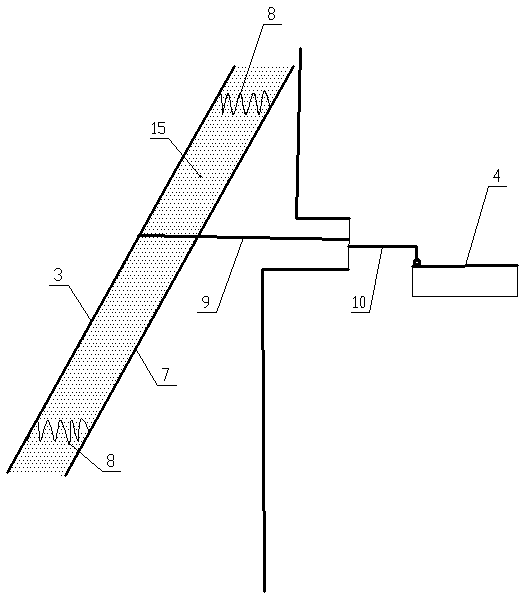

[0027] Such as figure 1 and figure 2 As shown, the cuttings amount testing device based on the pressure sensor of the present invention includes a hollow drill rod 1, a drill bit 2, a spiral plate 3, a sliding rheostat 4, a data converter 5 and a display 6, and the drill bit 2 is installed at the front end of the hollow drill rod 1 The outer circle of the hollow drill pipe 1 is provided with at least two helical blades 7 along the axial direction, the number of the helical plates 3 and the helical blades 7 is equal, and each helical plate 3 is correspondingly arranged in parallel on the front side of the front end of each helical blade 7 A number of springs 8 are arranged between the rear side of the spiral plate 3 and the spiral blade 7, and the front end of the hollow drill rod 1 is provided with a first guide hole that is transparent inside and outside along the radial direction, and the spiral blade 7 is provided with a 3 The second guide hole corresponding to the rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com