Defrosting device for dense heat exchanger

A heat exchanger, methanol technology, applied in heat exchange equipment, lighting and heating equipment, damage protection, etc., can solve the problems of reducing the temperature and partial pressure of the heat exchanger, loss of heat exchange efficiency, and no defrosting device. The effect of convenient operation, reduced loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

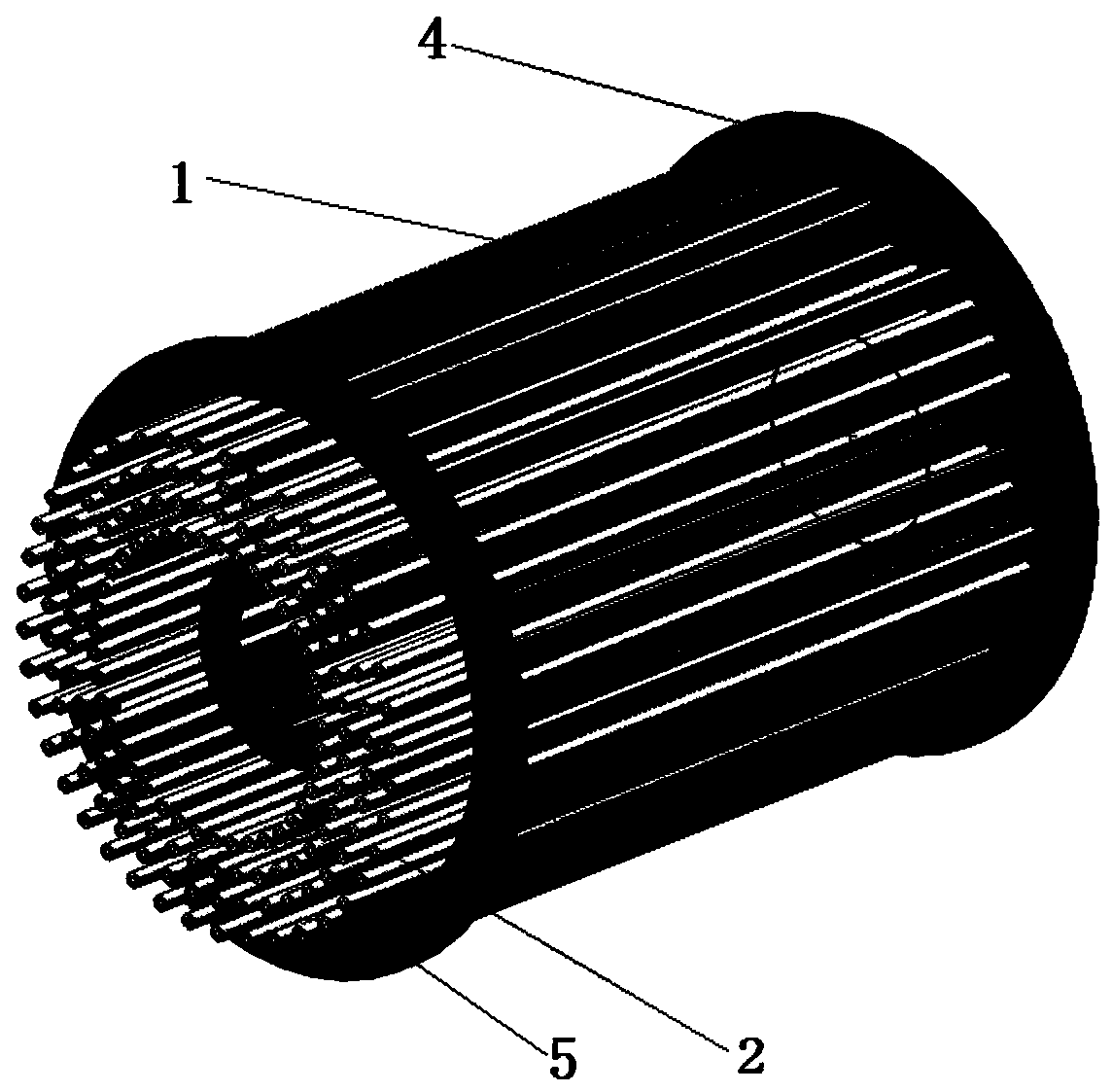

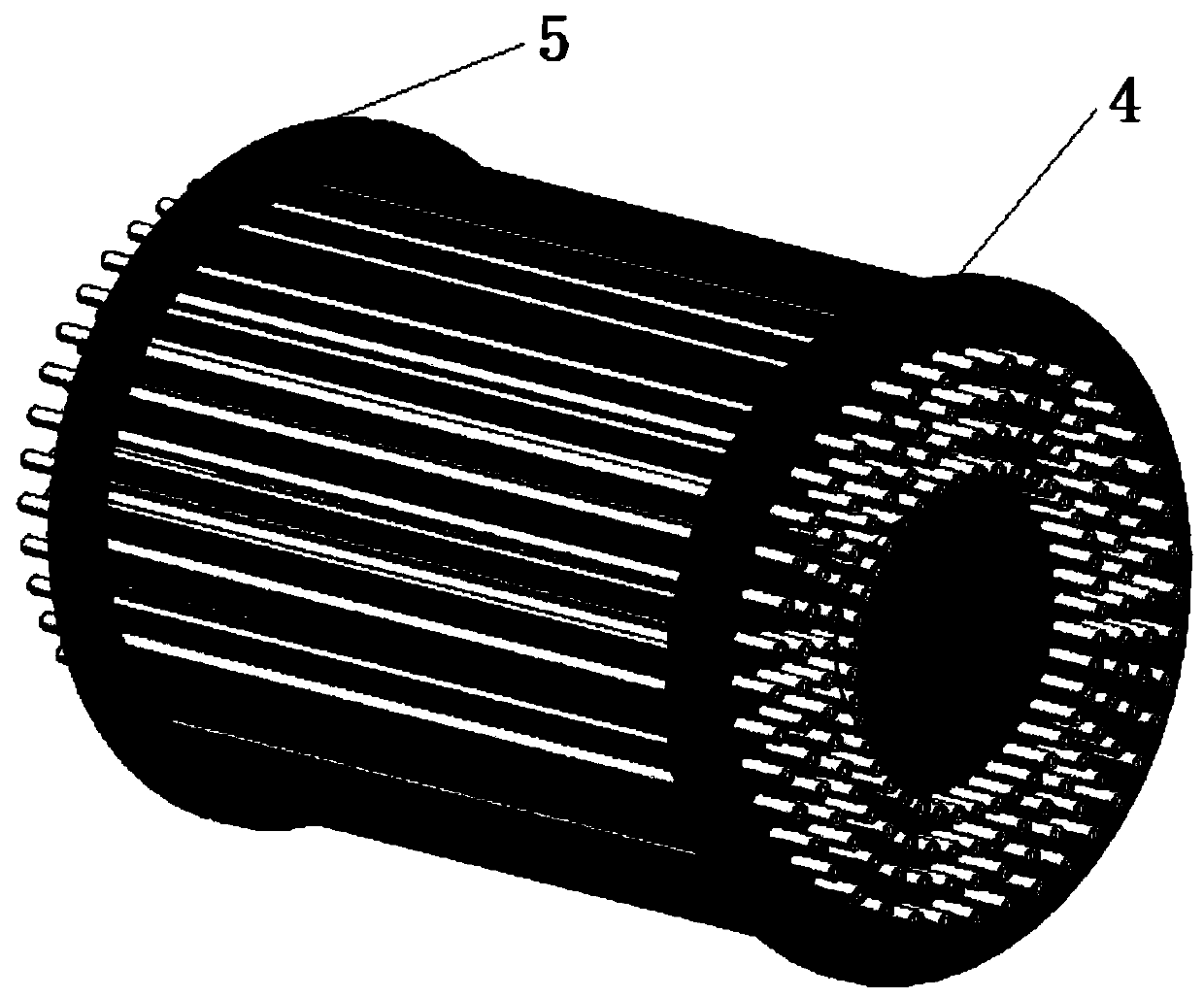

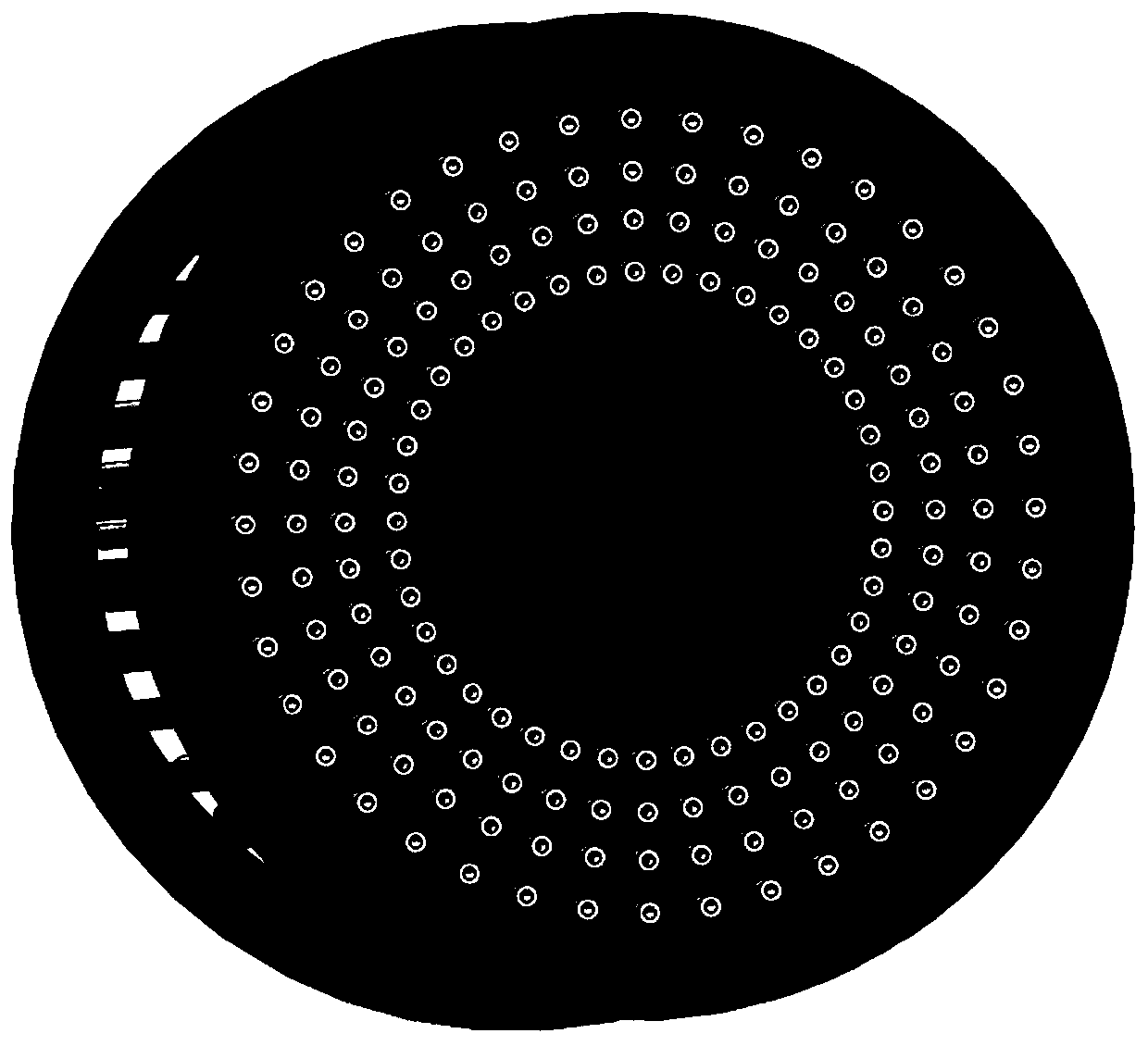

[0025] Specific implementation mode one: see Figure 1-Figure 6 This embodiment will be described. The defrosting device for a dense heat exchanger described in this embodiment includes several methanol injection pipes 1, several methanol absorption pipes 3, a bottom plate 4, an outer ring support plate 5 and an inner ring support plate 6, and the bottom plate 4 is A circular plate with a circular through hole is provided, the outer ring support plate 5 is located on the opposite side of the base plate 4, has a ring shape, and has the same diameter as the base plate 4, and several methanol injection pipes 1 are fixed on the base plate 4 and the base plate 4 at equal intervals. Between the outer ring support plates 5, the inner ring support plate 6 is located inside the outer ring support plate 5, and several methanol absorption pipes 3 are fixed between the bottom plate 4 and the inner ring support plate 6, and the bottom plate 4 is located The part between the outer ring sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com