Multi-physics dynamic parameter testing device for rolling bearing cage

A technology of dynamic parameters and rolling bearings, applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problem that it is difficult to obtain multi-degree-of-freedom motion, multi-point strain and temperature synchronization data, and cannot realize multi-physics parameter synchronization testing of cages, cages Problems such as the relationship between strain and temperature are not clear, so as to achieve the effects of reducing influence, small size and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention are described in detail below, which are shown in the drawings, wherein the same or similar reference numerals represent the same or similar elements, elements having the same or similar functions, throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0046] This example uses an inner ring guided ball bearing as an example, but it is not limited to the type of bearing, cage pocket and type of guidance.

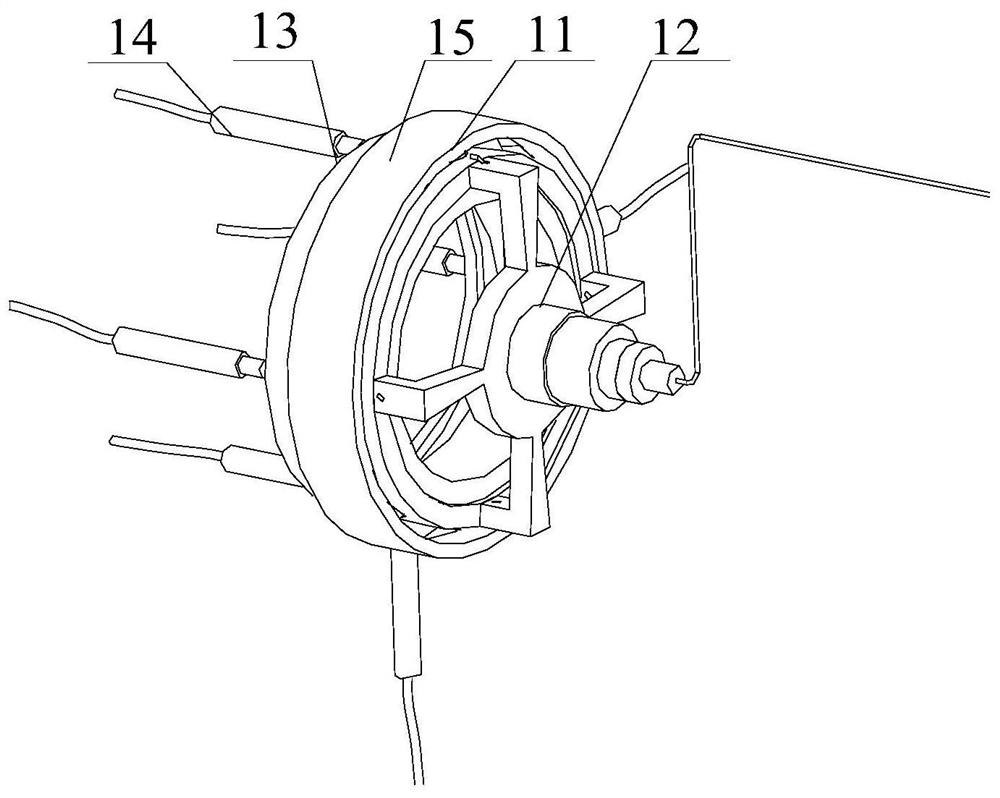

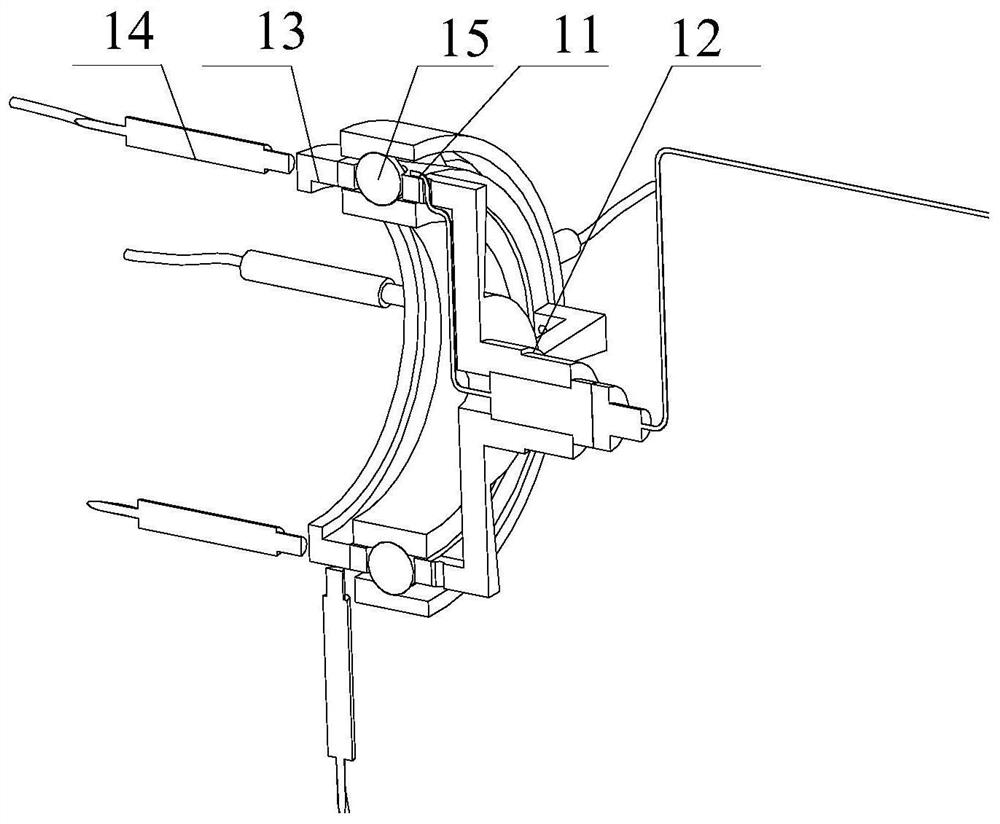

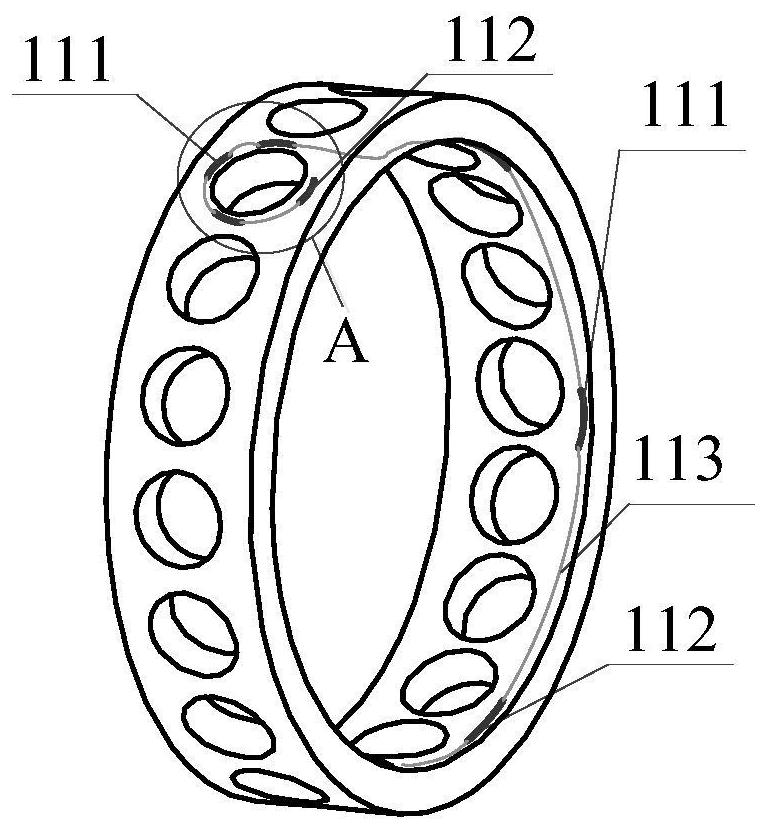

[0047] Such as Figure 8 As shown, a rolling bearing cage multi-physics dynamic parameter testing device includes a rolling bearing cage dynamic parameter testing device 1, a sensor testing system, a driving device 3, a radial loading device 4, an axial loading device 5, and a bearing housing 6, Realize the experimental test of the rolling bearing cage under a certain compound load and speed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com