Spherical liquid vibration damping device suitable for fan blades and installation method

A technology of wind turbine blades and vibration reduction devices, which is applied in the assembly of wind turbines, wind turbines, engines, etc., can solve the problems of reducing effective life, blade material fatigue, blade fracture, etc., and achieve the effect of improving the vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

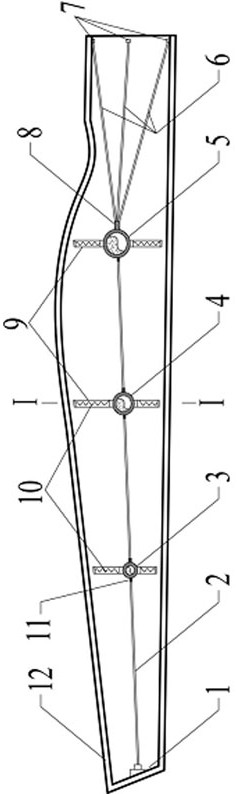

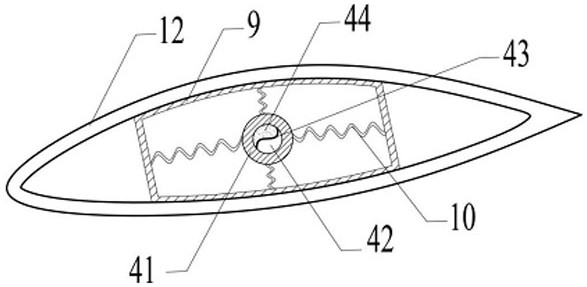

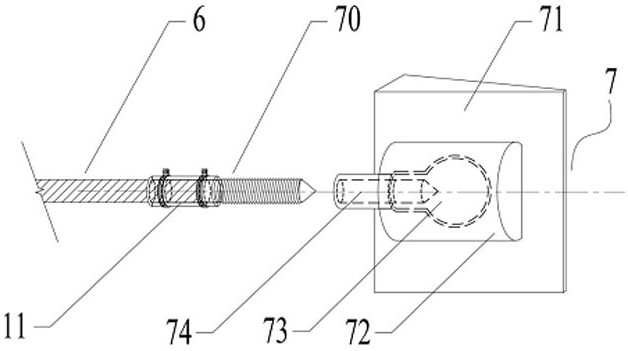

[0020] like Figure 1~Figure 5 As shown, the present invention is a spherical liquid damping device suitable for fan blades and an installation method, and the spherical liquid damping device suitable for fan blades includes a spherical mass, a return-type fixed plate 9, and a shape memory alloy spring 10 , an assembly and a fiber rope, the spherical mass block is provided with 3 diameters that increase sequentially from top to bottom, that is, No. 1 spherical mass 3, No. 2 spherical mass 4, and No. 3 spherical mass 5, Each spherical mass is composed of a hollow spherical shell 41, a full-carbon airgel 44 and a high-density liquid 42, wherein the full-carbon airgel 44 is packed in the hollow of the hollow spherical shell 41 after being wrapped with an elastic waterproof material 43, It occupies 1 / 2 of the hollow volume, and the remaining 1 / 2 hollow volume is filled with high-density liquid 42; the return-type fixed plate 9 is provided with 3 pieces corresponding to the 3 spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com