An experimental device for measuring the critical point of thermal deformation of a CNC machine tool bed and its determination method

A determination method and thermal deformation technology, applied in the field of CNC machine tools, can solve the problems of reducing the machining accuracy of machine tools, uneven temperature changes, and great influence of precision machining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, goals and effects realized by the present invention easy to understand, the present invention will be further described in detail below in conjunction with specific examples and illustrations. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention.

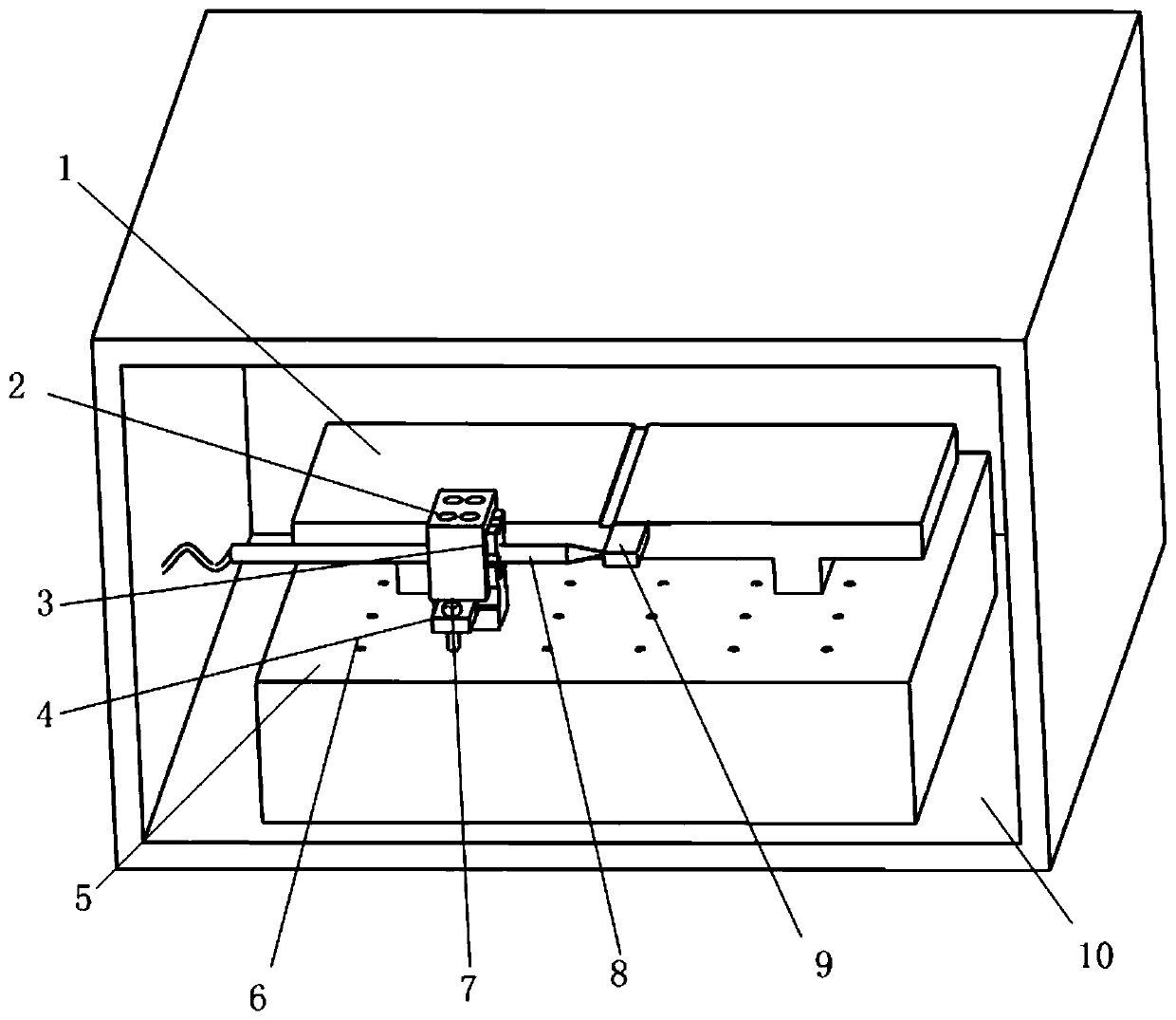

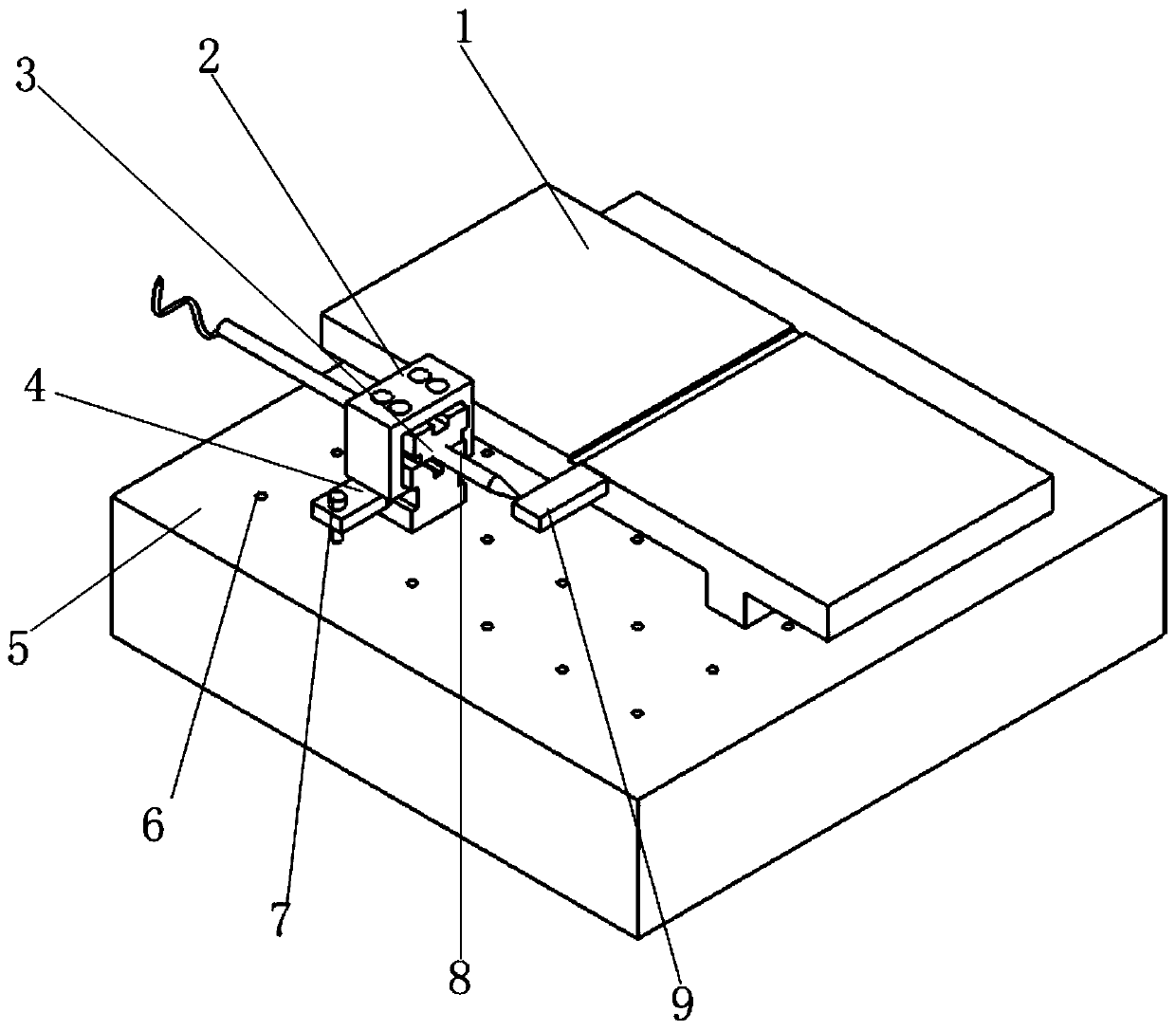

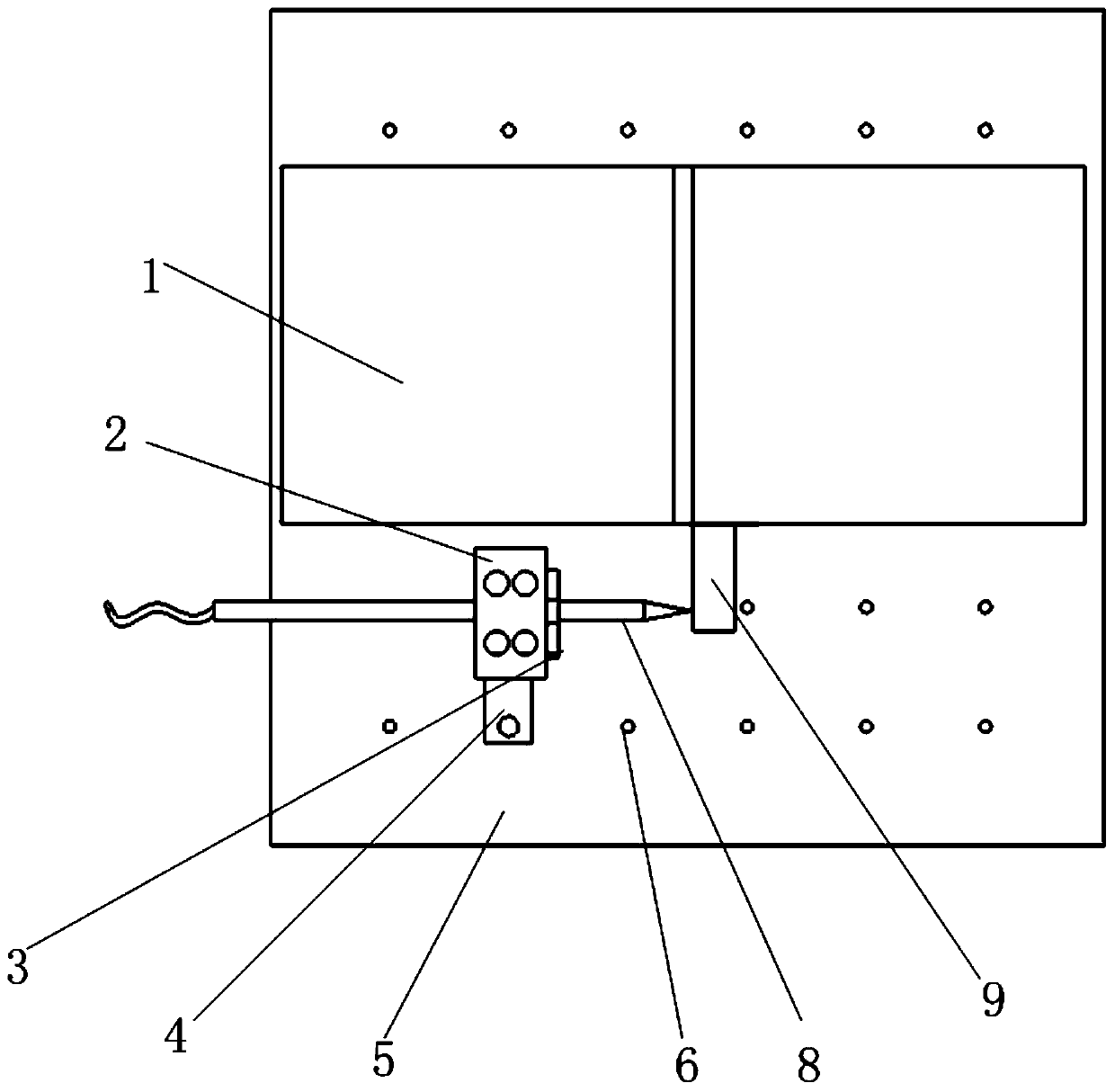

[0022] Such as figure 1 As shown, an experimental device for measuring the thermal deformation critical point of a CNC machine bed, including a machine bed miniature model 1, a clamping part 2, a V-shaped block 3, a pressure plate 4, a marble platform 5, a threaded hole 6, a screw 7, an inductor Micrometer 8, Invar block 9, temperature control box 10. Such as figure 1 As shown in , the V-shaped block 3 is firmly fixed on the marble platform 5 by the pressure plate 4 and the screw 7; the inductance micrometer 8 is fixed by the combined fixture composed of the clamping part 2 and the V-shaped block 3 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com