Preparation method for organic light emitting diode display device and display device

A technology for light-emitting diodes and display devices, which is applied in the fields of organic semiconductor devices, photovoltaic power generation, semiconductor/solid-state device manufacturing, etc., can solve problems such as device failure, and achieve the effect of improving water and oxygen resistance and ensuring packaging reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

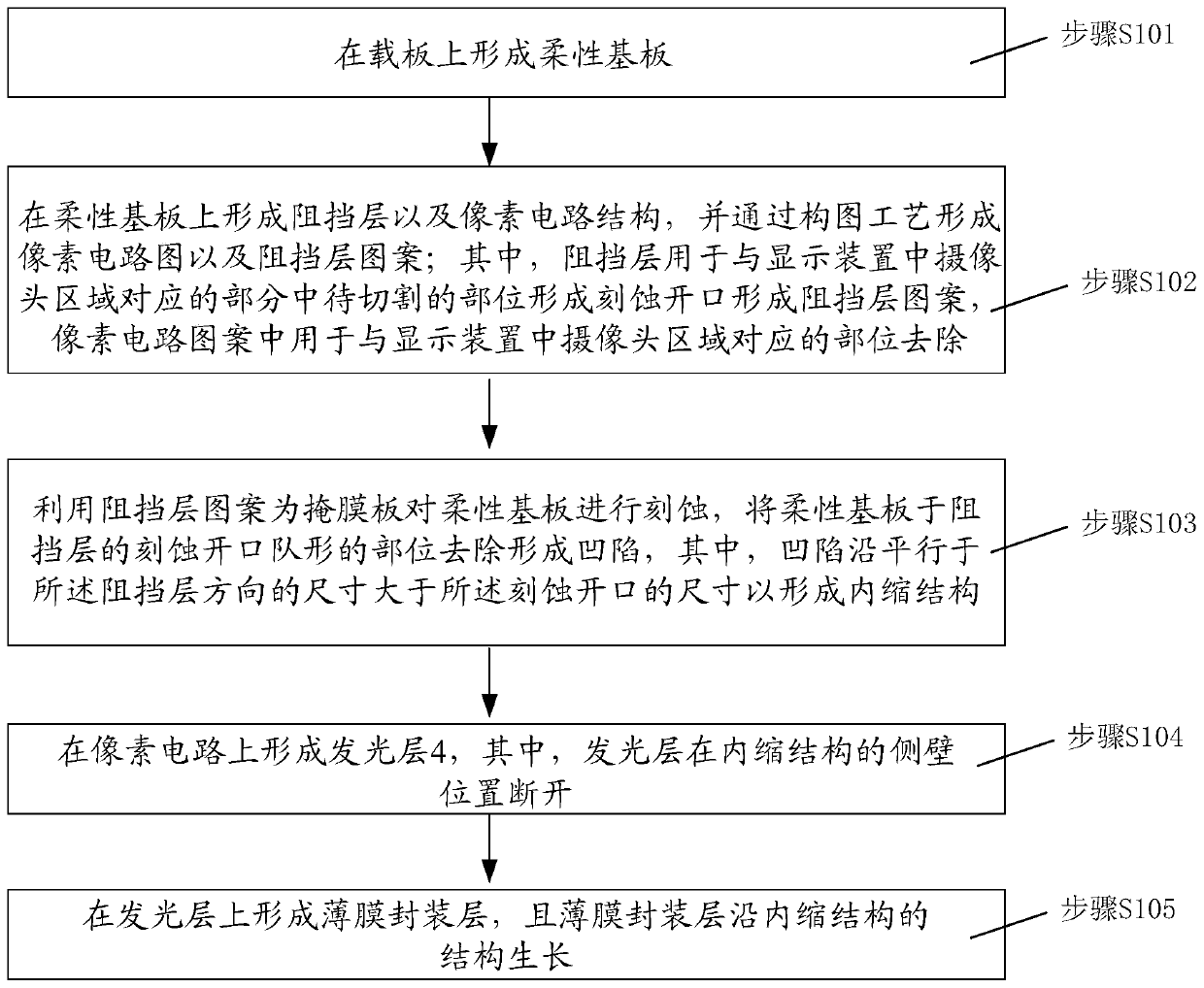

[0036] Please refer to figure 1 , the invention provides a method for preparing an organic light emitting diode display device, comprising:

[0037] Step S101: forming a flexible substrate 1 on a carrier;

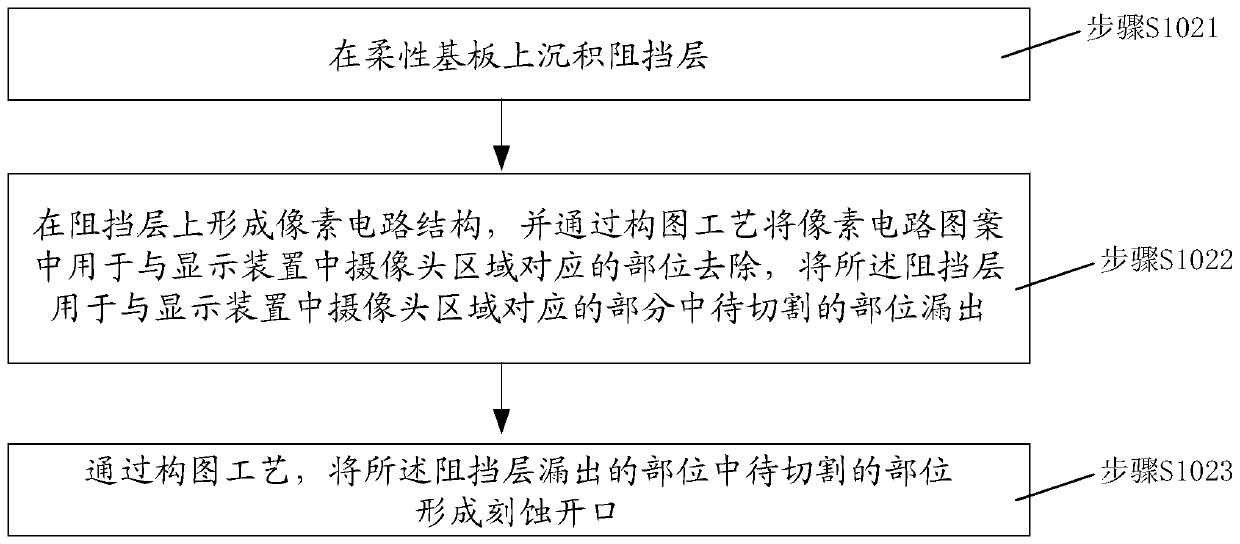

[0038] Step S102: Form a barrier layer 2 and a pixel circuit structure 3 on the flexible substrate 1, and form a pixel circuit through a patterning process image 3 And the barrier layer 2 pattern; wherein, the barrier layer 2 is used to form an etching opening in the part to be cut in the part corresponding to the camera area in the display device to form a barrier layer pattern, and the pixel circuit pattern is used in the pixel circuit pattern corresponding to the camera area in the display device site removal;

[0039] Step S103: Etching the flexible substrate 1 by using the barrier layer pattern as a mask, removing the flexible substrate at the position of the etching opening formation of the barrier layer to form a depression, wherein the depression is along a dimen...

Embodiment example

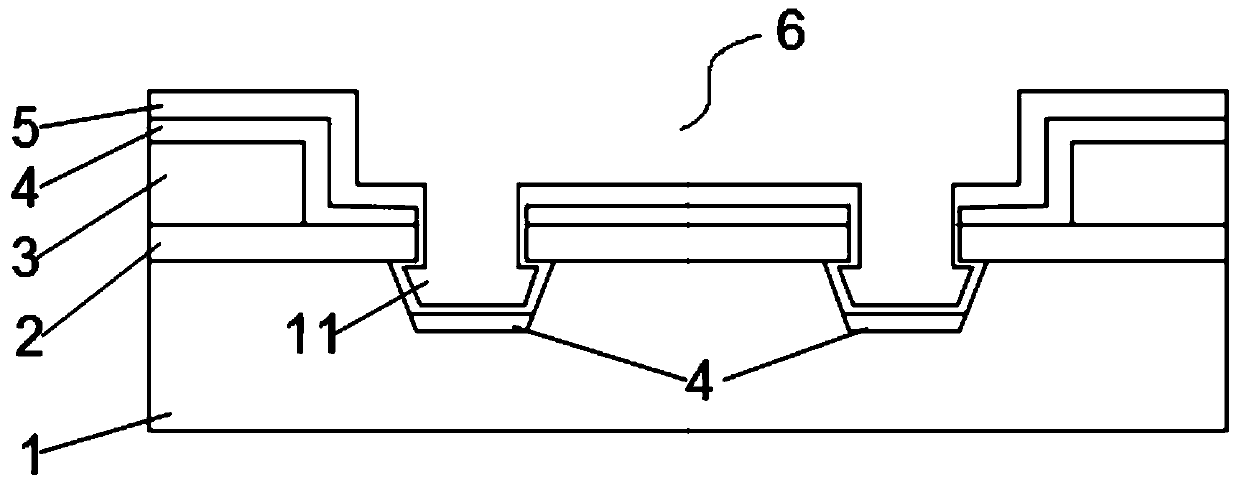

[0055] As a possible implementation example of the above-mentioned thin film encapsulation layer, the thin film encapsulation layer 5 includes a first organic layer, an inorganic layer, and a second organic layer located on the side of the inorganic layer away from the first organic layer, wherein the first organic layer is The sidewall position of the retracted structure is disconnected. Since the organic layer has a greater effect on the thin film encapsulation layer 5 to improve flatness and reduce mechanical damage, and at the same time, because the light-emitting layer 4 is disconnected at the inner shrinkage structure 11, the first organic layer is omitted, and materials are also saved. .

[0056] In addition, the present invention also provides a display device, such as image 3 As shown, it includes: a flexible substrate 1, a barrier layer 2, a pixel circuit structure 3, a light emitting layer 4 and a thin film encapsulation layer 5, wherein the side of the flexible s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com