A low-temperature heating method based on temperature change for lithium-ion batteries with alternating excitation

A lithium-ion battery, temperature change technology, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as poor charge and discharge performance, and achieve the best low-temperature self-heating effect of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

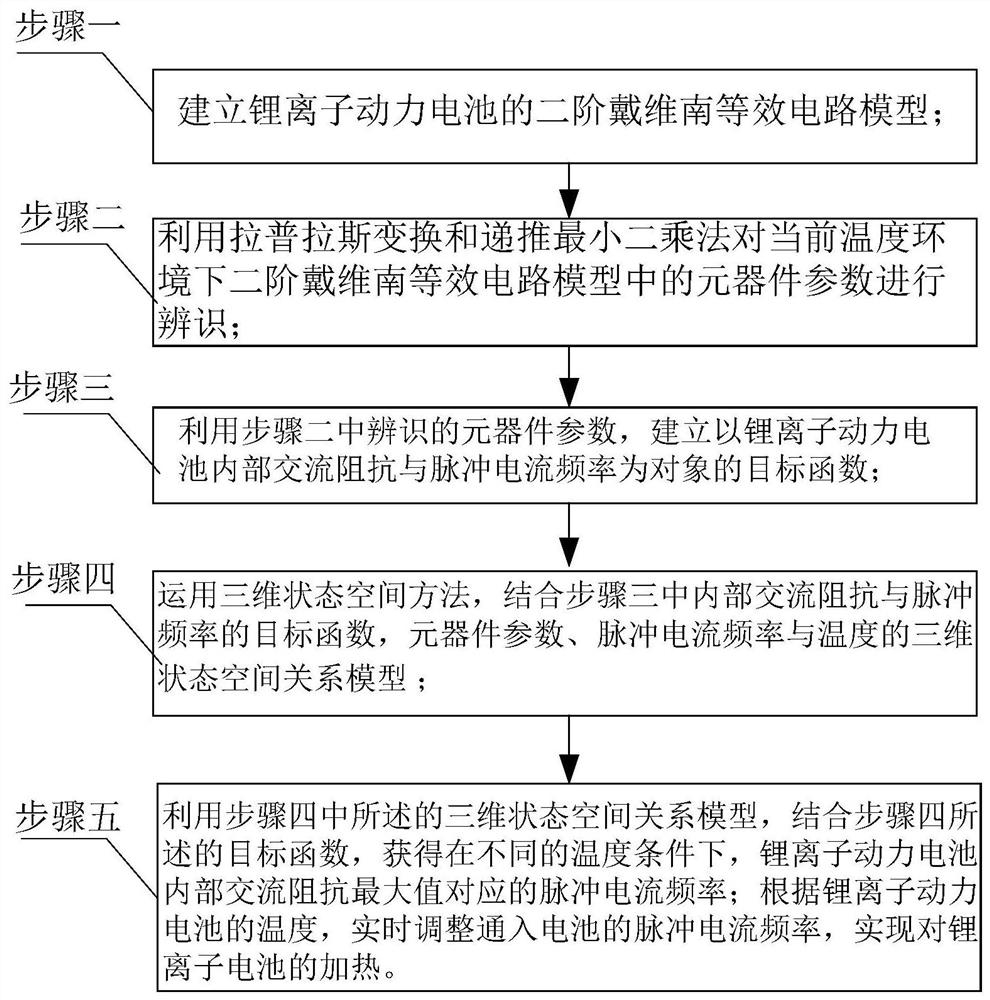

[0015] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a method for heating lithium-ion batteries based on temperature changes under alternating excitation low-temperature heating described in this embodiment, the method includes:

[0016] Step 1: Establish the second-order Thevenin equivalent circuit model of the lithium-ion power battery;

[0017] Step 2: Use Laplace transform and recursive least squares method to identify the parameters of components in the second-order Thevenin equivalent circuit model under the current temperature environment;

[0018] Step 3: Using the component parameters identified in Step 2, establish an objective function that takes the internal AC impedance and pulse current frequency of the lithium-ion power battery as objects;

[0019] Step 4: Using the three-dimensional state space method, combined with the objective function of internal AC impedance and pulse frequency in step three, establish a th...

specific Embodiment approach 2

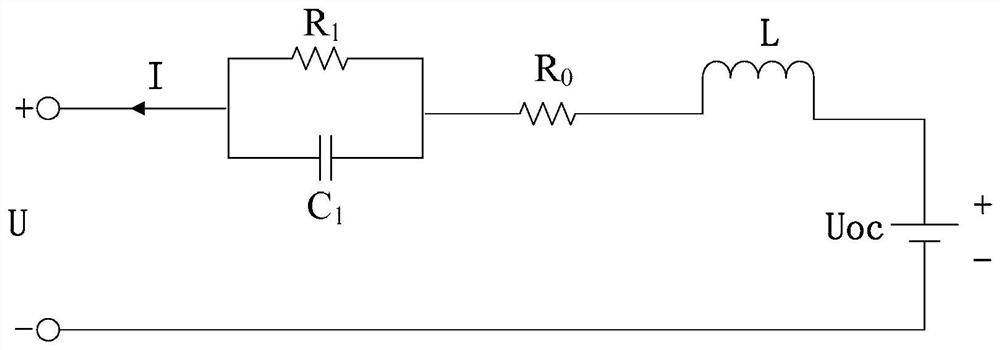

[0021] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment will further explain a kind of lithium-ion battery alternating excitation low-temperature heating method based on temperature change described in the first embodiment, the second-order Thevenin equivalent of the lithium-ion power battery described in step 1 The circuit model includes the polarization internal resistance R 1 , Polarized capacitance C 1 , equivalent internal resistance R 0 , equivalent inductance L and open circuit equivalent voltage source U oc ;

[0022] Polarization internal resistance R 1 One end of the polarized capacitor C 1 One end is connected, and the polarization internal resistance R 1 The end of this terminal is connected to the positive pole of the charging power supply; the polarization internal resistance R 1 The other end of the polarized capacitor C is connected at the same time 1 The other end and the equivalent interna...

specific Embodiment approach 3

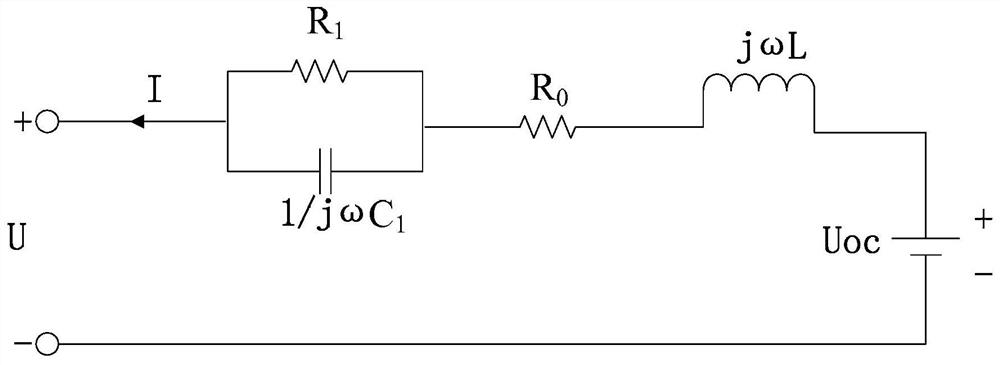

[0023] Specific implementation mode three: the following combination figure 2 Describe this embodiment, this embodiment will further explain a kind of lithium-ion battery alternating excitation low-temperature heating method based on temperature change described in the second embodiment, the second-order Thevenin equivalent circuit of the lithium-ion power battery described in step 1 The formula for the model is:

[0024]

[0025] Among them, U oc is the open circuit voltage of the lithium-ion battery, R 0 is the ohmic internal resistance of the lithium-ion power battery, R 1 is the polarization internal resistance of the lithium-ion power battery, C 1 is the polarized capacitance of the lithium-ion power battery, U is the terminal voltage of the lithium-ion power battery, L is the equivalent inductance of the lithium-ion power battery, I is the charging current of the lithium-ion battery, and s is a variable in the frequency domain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com