Manufacturing method of golden finger circuit board

A production method and gold finger technology, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., to achieve the effect of optimizing the production process and enhancing the ability of sealing grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

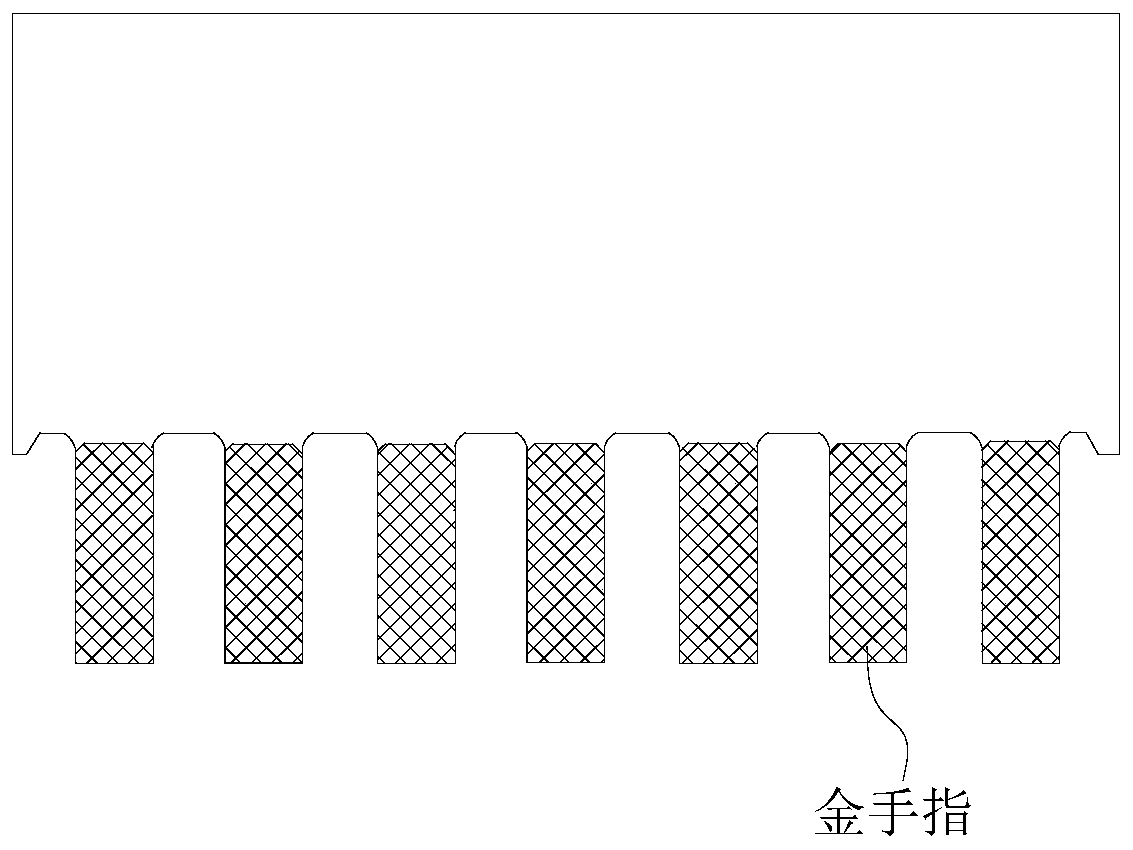

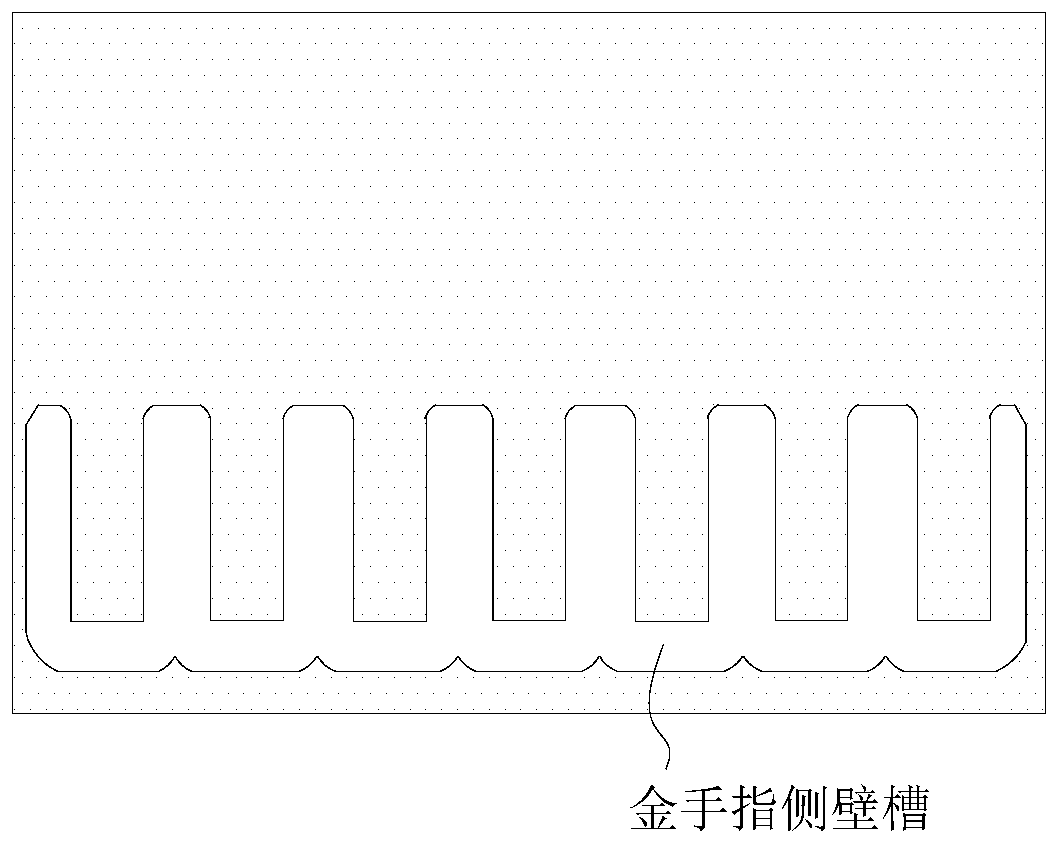

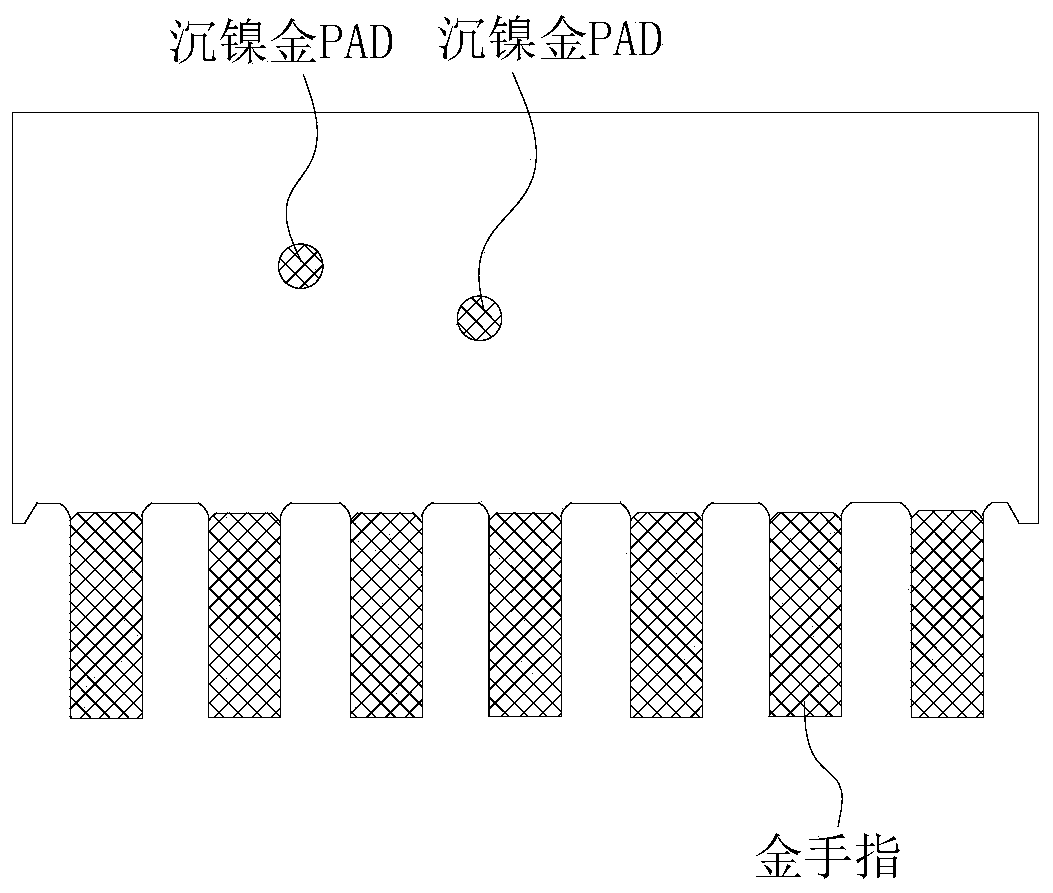

[0030] This embodiment provides a method for manufacturing a gold finger circuit board. The thickness of the produced gold finger circuit board is less than 1mm, the three sides of the gold finger are plated with gold, the side wall groove of the gold finger is larger than 2.5mm×9mm, and the PAD on the board surface is sunk Nickel gold finish.

[0031] The board surface of the production board processed in the production process is divided into a circuit area and a gold finger area, and the gold finger area includes a gold finger position for making a gold finger and a side wall groove for making a gold finger side wall groove, and the manufacturing method as follows:

[0032] (1) Cutting: cut out the inner core board according to the panel size required by the design.

[0033] (2) Fabricate the inner layer circuit: adopt the negative process to fabricate the inner layer circuit on the inner layer core board to obtain the inner layer circuit board. After etching the inner la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com