Printing unit

A technology of assembly and printing head, applied in the field of printing assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

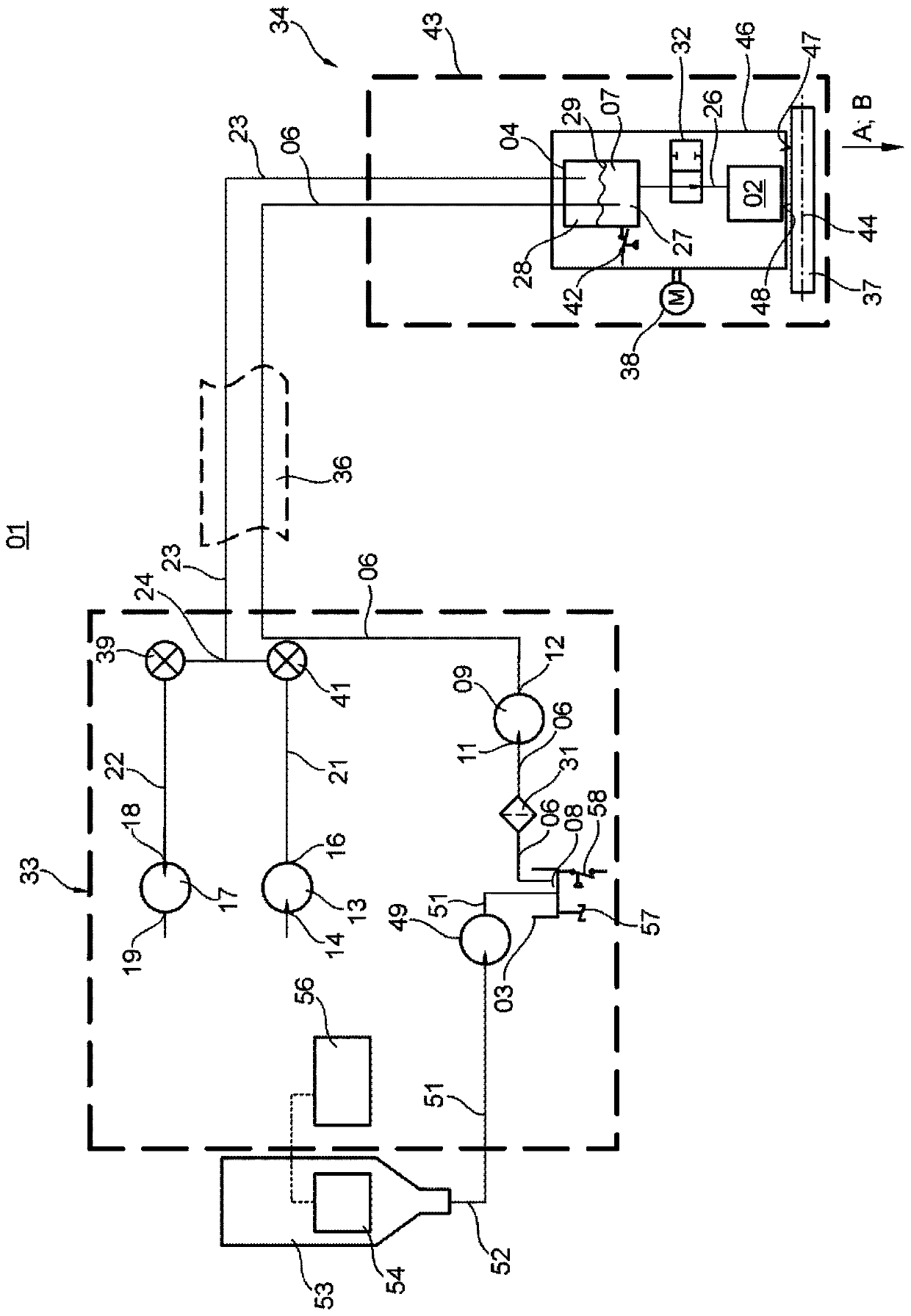

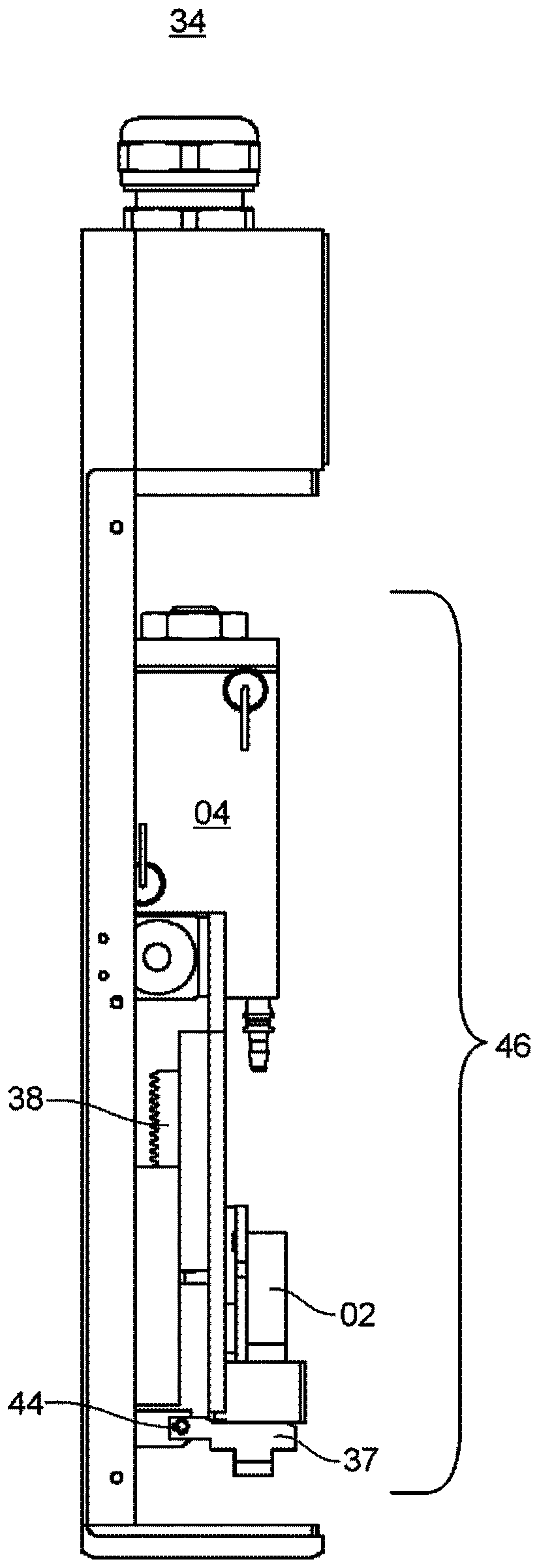

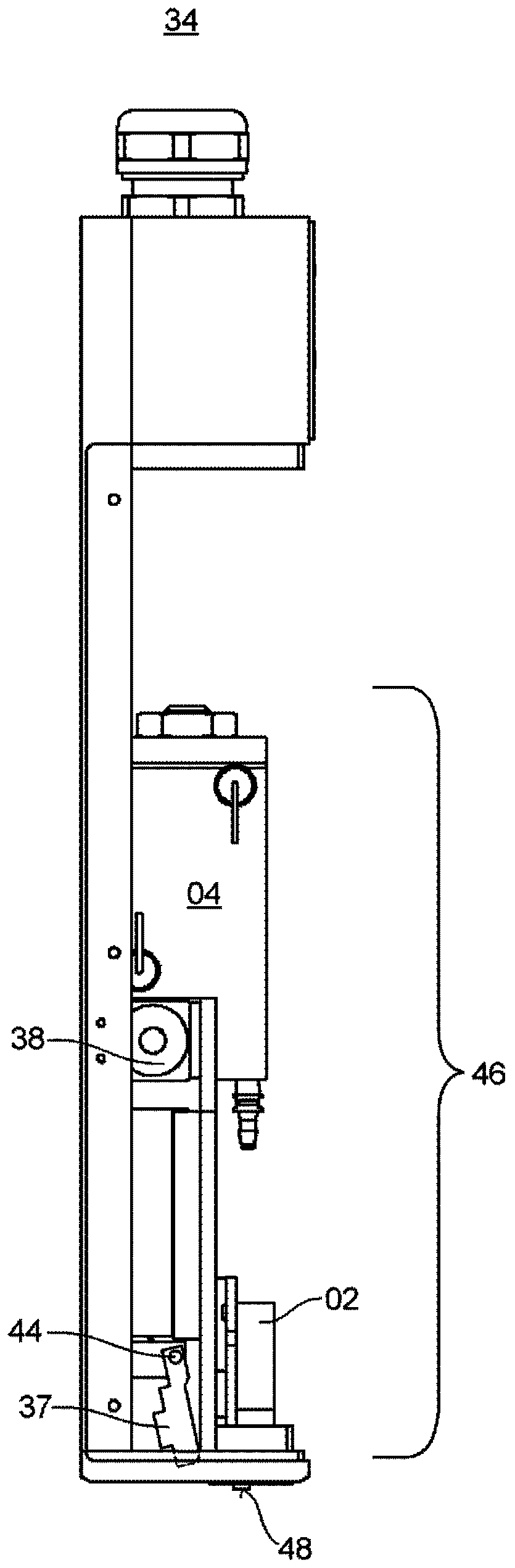

[0038] The printing unit 01 has at least one printing head 02 . The at least one printing head 02 is preferably designed as an inkjet printing head 02 . The at least one printing head 02 is preferably a printing head 02 which is arranged in a fixed position during the printing operation. The printing unit 01 preferably has at least one storage container 03 for application medium, in particular ink, and at least one balancing container 04 . The coating medium or ink is preferably fed from the storage container 03 via the compensating container 04 into the printing head 02 and emerges from the printing head 02 where it is applied to the corresponding printing material.

[0039] The compensating container 04 has at least one and preferably exactly one interior space 07 . Inner space 07 of compensating container 04 is provided in particular to accommodate at least one first liquid volume 27 of coating medium, in particular ink. Preferably, the interior 07 of the compensating co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com