One-step process of producing magnesium hydroxide

A technology of magnesium hydroxide and footwork, applied in the direction of magnesium hydroxide, etc., can solve the problems of scarring of equipment and pipelines, long production cycle, high production cost, etc., and achieve the effect of good product quality, stable product quality and constant operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

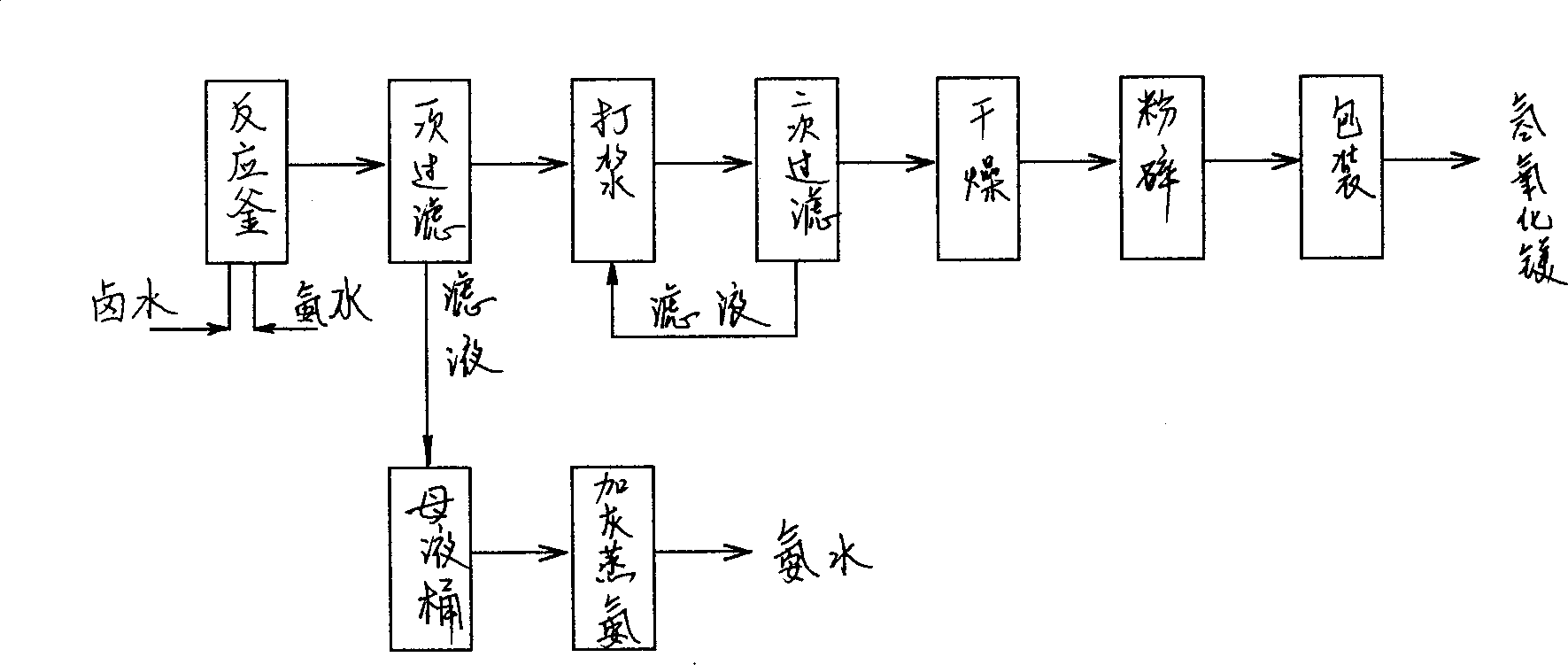

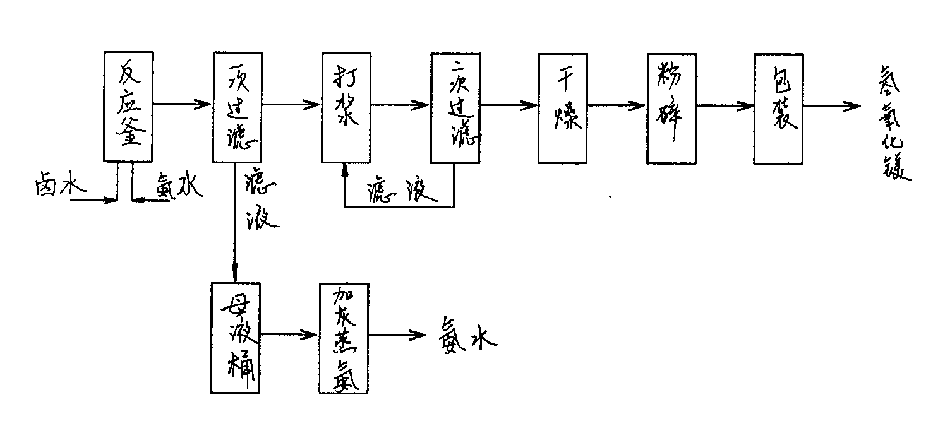

Image

Examples

Embodiment 1

[0011] As shown in the accompanying drawing, first prepare qualified hot ammonia water and refined brine, measure the content of magnesium chloride and free ammonia in it, mix them into the reaction kettle according to the molar ratio of magnesium chloride and free ammonia as 1:1.6, After stirring and reacting at a temperature of 50 degrees for 20 minutes, pump the reaction liquid to a primary filter for solid-liquid separation and washing. The filtrate after primary filtration is distilled with lime to prepare ammonia water, which can be used as a raw material for the production of magnesium hydroxide ;The filter cake after the primary filtration is added with water and then subjected to secondary filtration, the solid material is sent to the beating kettle, and fresh water is added for beating, and then pumped to the secondary filter for filtration and washing. Both the primary filter and the secondary filter can be used Use a common filter press. The solid material after th...

Embodiment 2

[0021] Embodiment 2: production step is the same as embodiment 1, and the mol ratio of magnesium chloride and free ammonia is 1: 1.6, stirs and reacts 30 minutes under the temperature of 80 degrees centigrade, then obtains solid magnesium hydroxide by filtering-beating-filtering-drying process .

Embodiment 3

[0022] Embodiment 3: production step is the same as embodiment 1, and the mol ratio of magnesium chloride and free ammonia is 1: 2, stirs and reacts 10 minutes under the temperature of 70 degrees centigrade, then obtains solid magnesium hydroxide by filtering-beating-filtering-drying process .

[0023] In the technical scheme of the present invention, the proportioning of ammoniacal liquor and brine should be that the consumption of ammoniacal liquor is more the better, and the consumption of ammoniacal liquor is more thoroughly that magnesium hydroxide is separated out, and reaction speed is faster, but considering the production cost aspect Factors, the amount of ammonia should not be less than 1.3 times the theoretical amount. When the amount is lower than 1.3 times, there may be more magnesium ions remaining in the brine that cannot be separated out, the reaction time will be prolonged, and the production cost is higher; when the amount of ammonia water is higher than 2 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com