Method and device for the functional testing of a fibre-optic sensor and computer program product

A fiber optic sensor and functional testing technology, which is applied in the direction of using optical devices to transmit sensing components, mechanical equipment, and measurement of the force of changes in optical properties of materials when they are stressed, and can solve the problem of determining the wrong state of measurement signal technology facilities, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following text, unless stated otherwise, the same reference signs are used for the same elements and the same active elements.

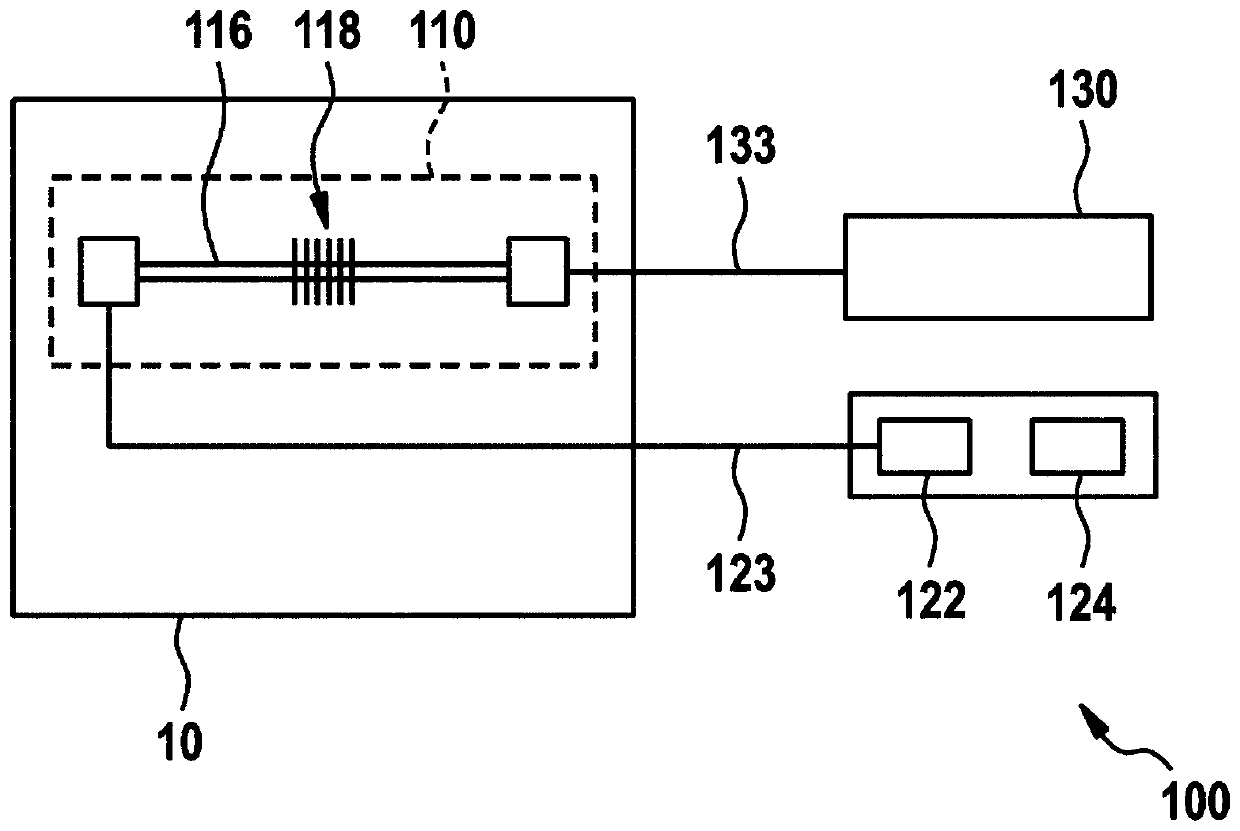

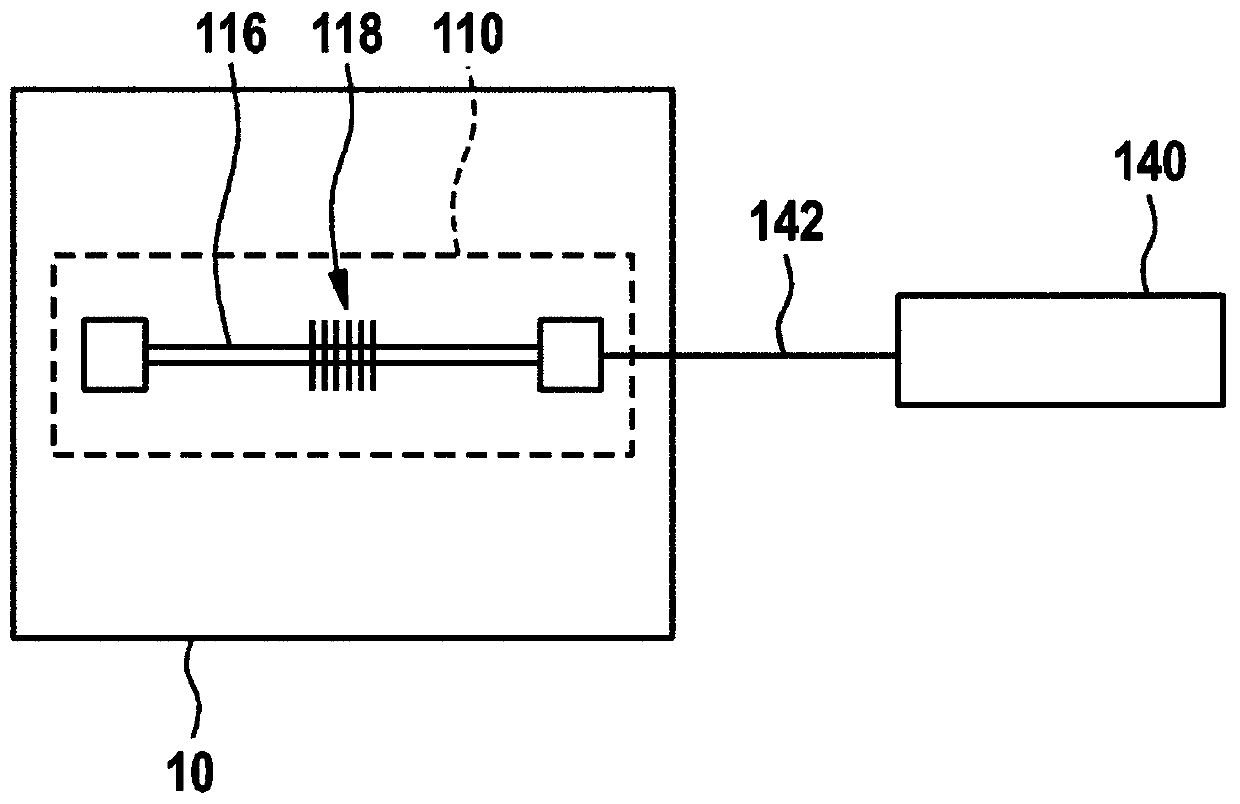

[0017] Figure 1A A schematic diagram of a device 100 for functional testing of an optical fiber sensor 110 according to an embodiment of the present disclosure is shown. Therefore, the fiber optic sensor 110 is shown by way of example only. Other types of fiber optic sensors may be used with embodiments of the present disclosure.

[0018] The device 100 comprises: a receiving unit 122 for receiving an optical sensor signal output by the fiber optic sensor 110 ; and an evaluation unit 124 . The evaluation unit 124 is configured to determine the first variable according to the optical sensor signal; determine whether the first variable is within a predetermined range; if the first variable is outside the predetermined range, then determine the failure of the fiber optic sensor 110; if it is determined that the first variable is within t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com