Impurity rethreshing lifting trough

A technology for waste and trough transportation, which is applied in threshing equipment, application, agricultural machinery and implements, etc. It can solve the problems that affect the cleaning effect and complex structure, and achieve the effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

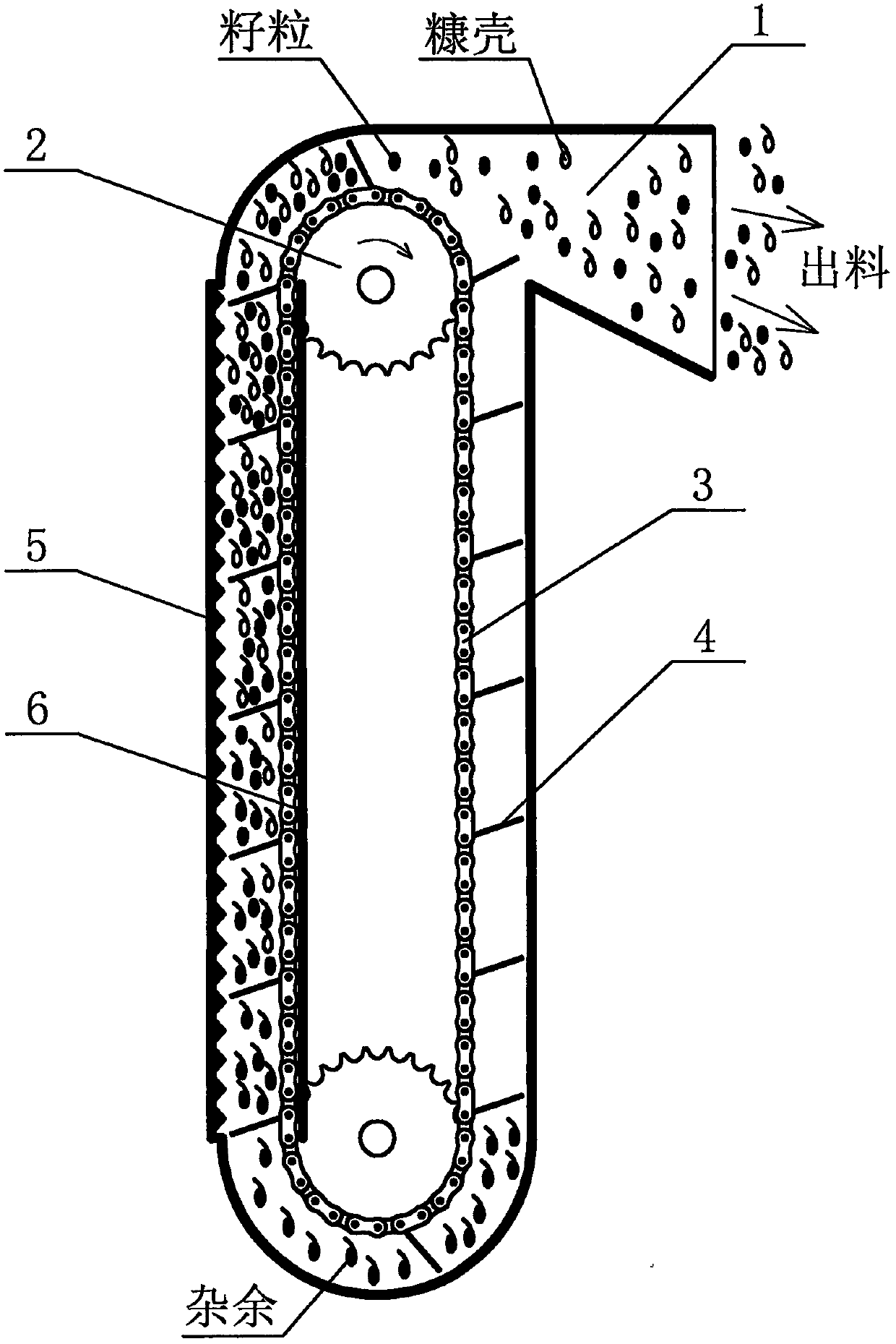

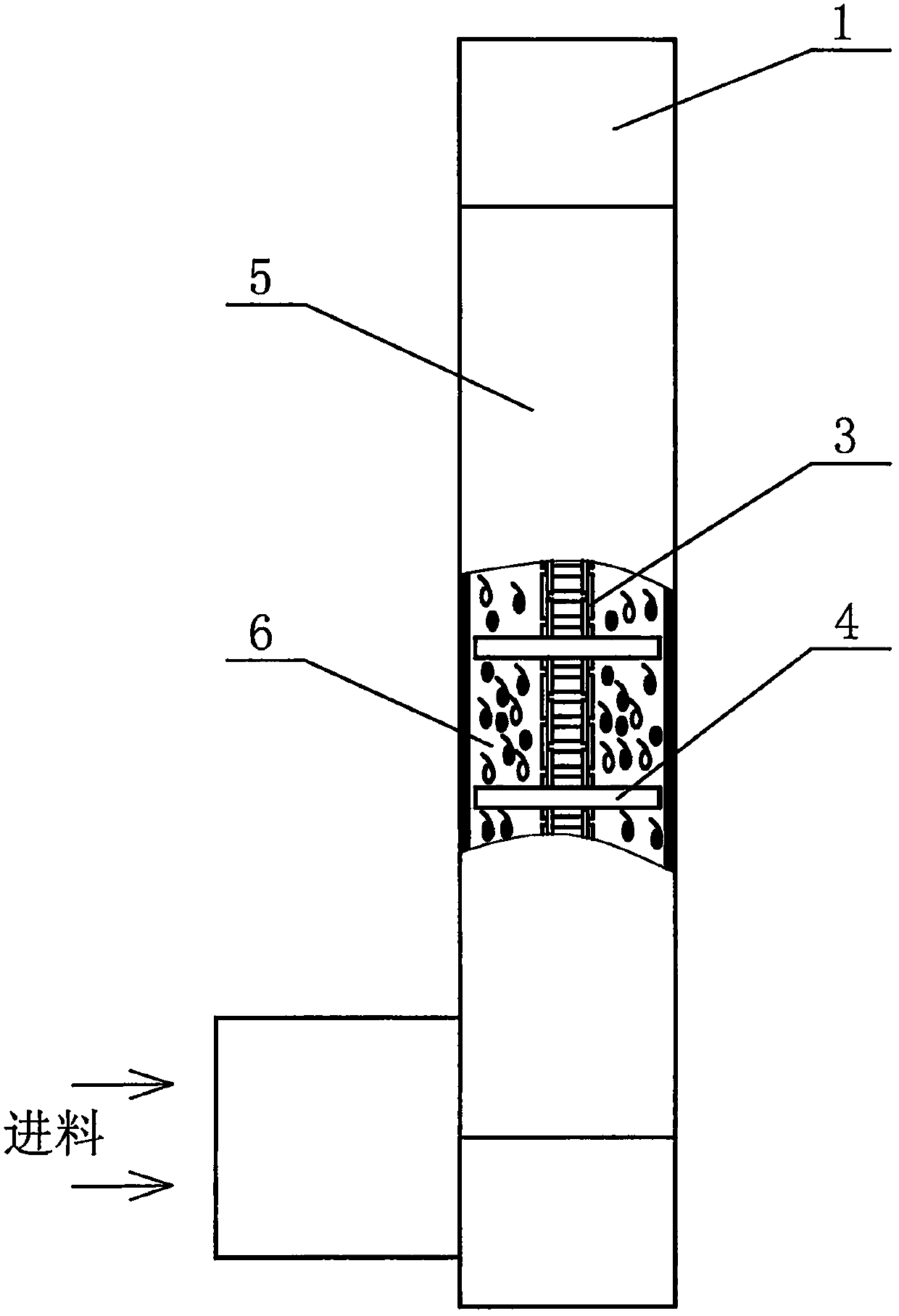

[0009] A kind of lifting tank for extra complex removal, which includes a lifting shell (1), a partition (6) that divides the lifting shell (1) into two sides, and sprockets (2) installed at the upper and lower ends of the lifting shell (1). ), the lifting chain (3) installed on the sprocket (2), the lifting bracket (4) fixed on the lifting chain (3), the washboard (5) fixed on the inner wall of the lifting shell (1) ).

[0010] The lifting bracket surface on the lifting chain is at an obtuse angle to the driving direction of the lifting chain.

[0011] The washboard on the inner wall of the lifting shell is fixed on the inner wall of the lifting shell on the side with a partition, which is conducive to rubbing the debris between the lifting bracket and the washboard.

[0012] The surface of the lifting bracket and the driving direction of the lifting chain form an obtuse angle. When the lifting chain is driven to the side where the washboard is installed, the driving directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com