Scribing method for brittlement substrate web with precision laser and special-purpose equipment

A special equipment and base material technology, which is applied in the field of precision laser scribing of brittle base materials and special equipment, can solve the problems of difficulty in ensuring the coincidence accuracy of scribe lines on the upper and lower sides, and low efficiency, so as to improve cost performance, competitiveness, and guarantee Machining accuracy, machining efficiency, and the effect of reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

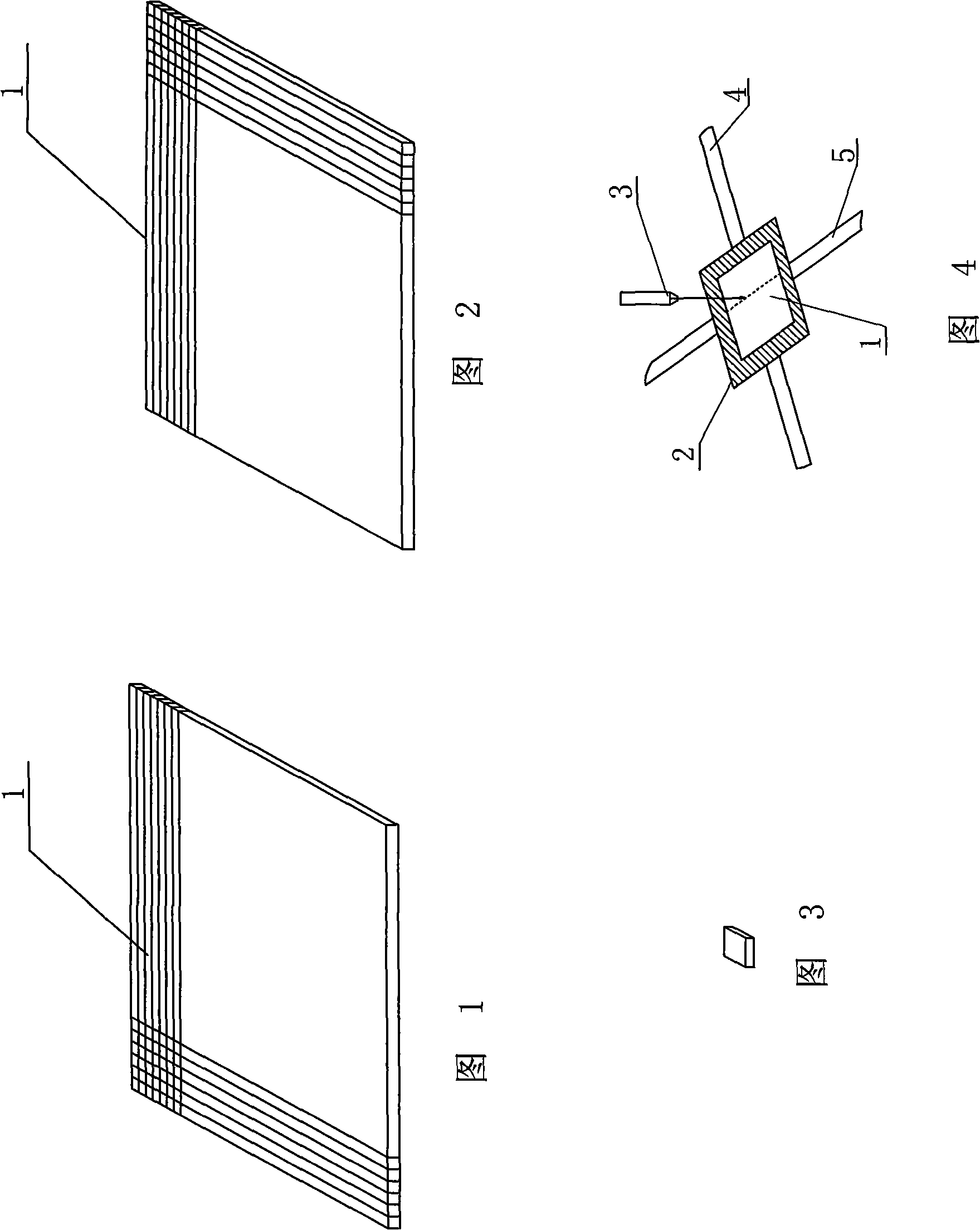

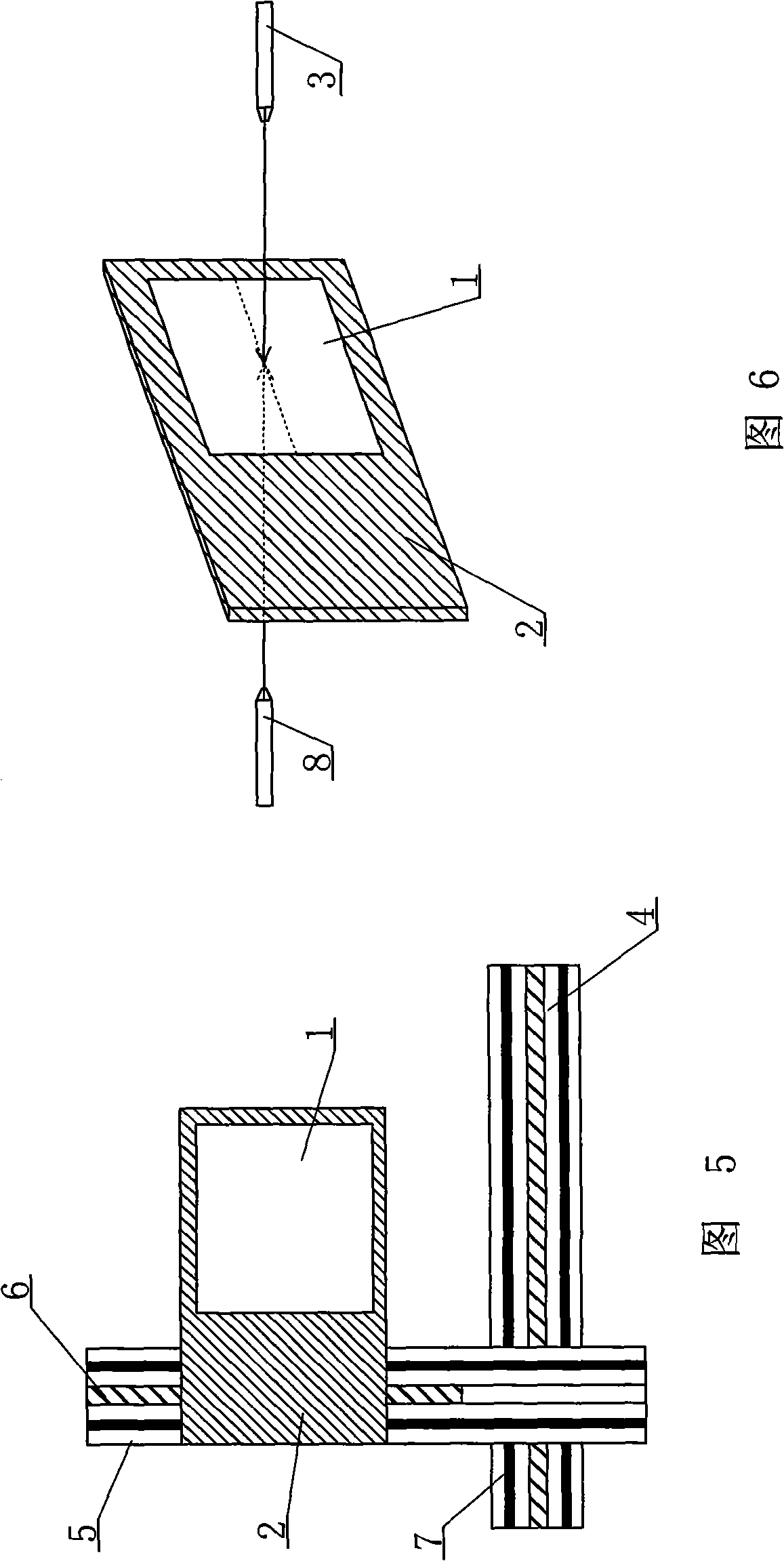

[0017] See Fig. 5 and Fig. 6, the special equipment for precision laser scribing micro-parts, which includes an X-axis-Y-axis moving table and at least one pair of laser heads 3,8. The X-axis 4 and Y-axis 5 of the mobile worktable are arranged in the vertical plane; the Y-axis 5 of the mobile worktable is embedded in the slide rail 7 of the X-axis 4 and connected with the X-axis 4 with threads, and the chuck for clamping the base material 2 and the Y-axis 5 are threadedly connected, and the chuck frame of the chuck 2 clamping the base material is arranged in a vertical plane. The processing process of the present invention is described below in conjunction with accompanying drawing: base material 1 is installed in the mouth frame of chuck 2, and base material 1 is arranged vertically, and when marking the line horizontally on base material 1 surface, laser head 3,8 After alignment, the X-axis 4 drives the Y-axis 5 to move in the horizontal direction, and the laser heads 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com