A method for installing a wind power generation wind measuring tower bracket

An installation method and wind measuring tower technology, applied in wind power generation, towers, building types, etc., can solve problems such as left and right swings, heavy brackets, and inability to resist strong winds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

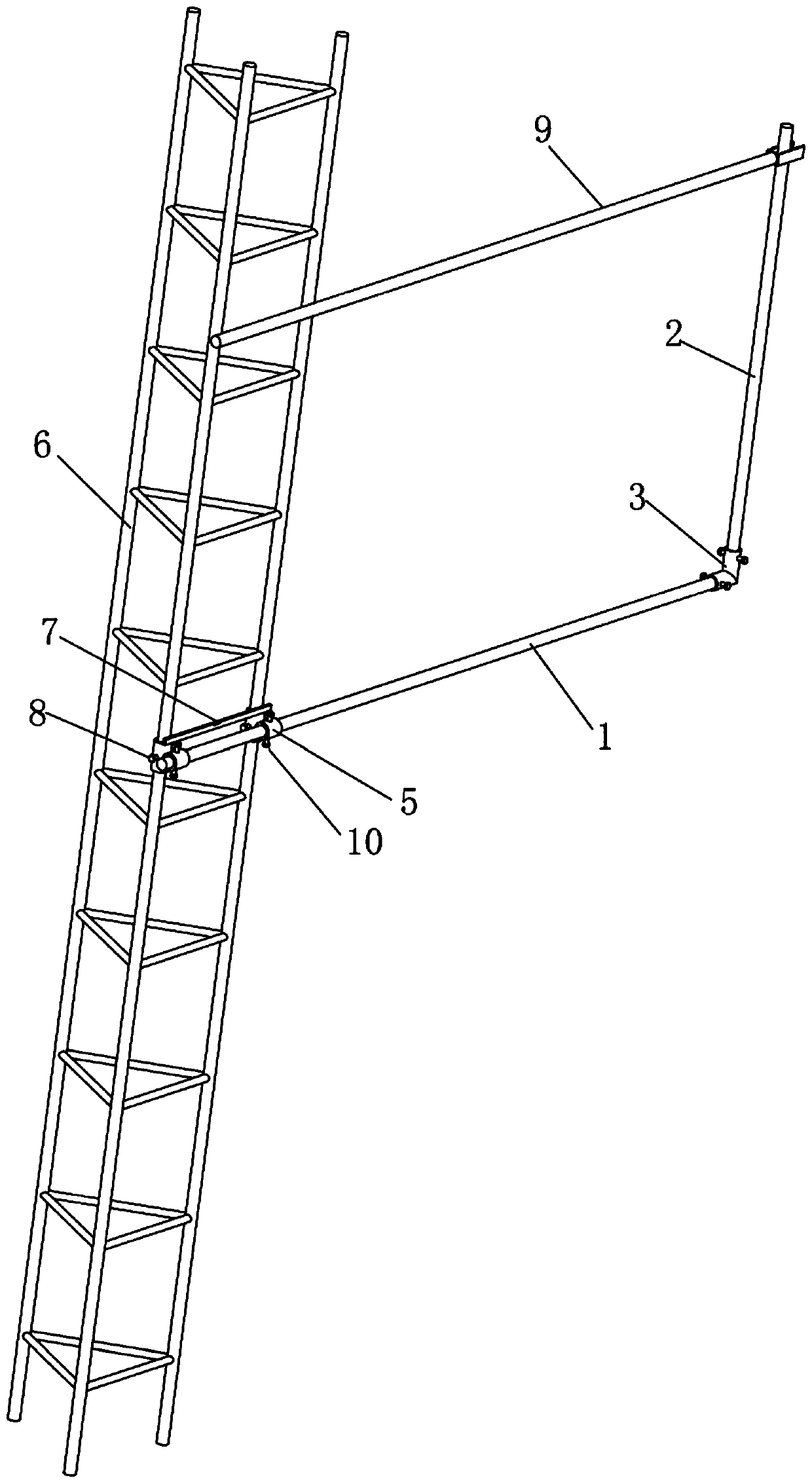

[0028] Such as Figure 1 to Figure 4 As shown, the installation method of the wind power generation anemometer tower support provided in this embodiment, its specific installation process is as follows:

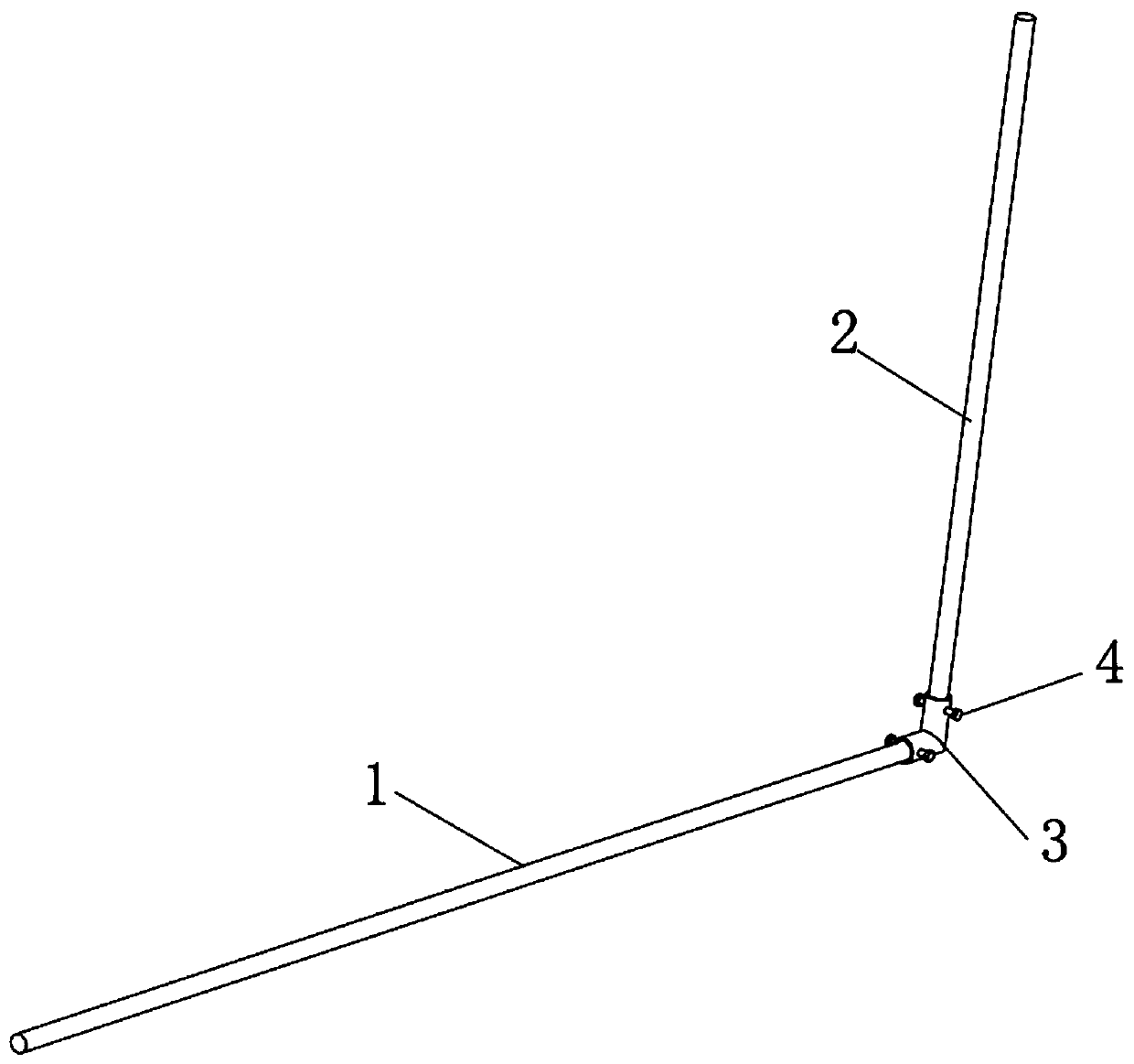

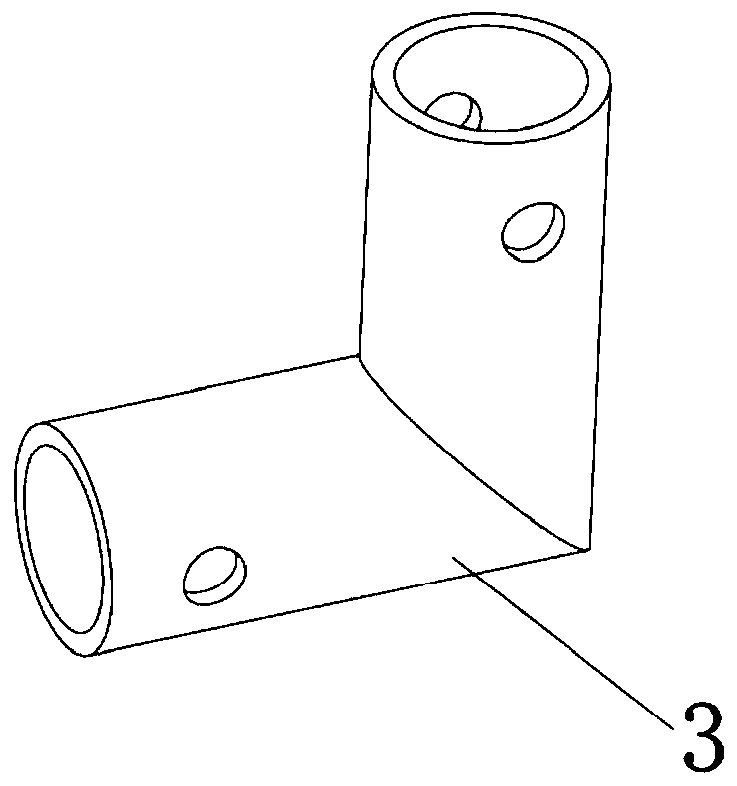

[0029] 1) Transport the prepared horizontal bar 1, vertical bar 2, right-angle sleeve 3 and the auxiliary alignment device 9 for correcting the verticality of the vertical bar 2 to the installation site, and place the horizontal bar 1 and the vertical bar 2 on the ground Insert the right-angled sleeve 3, assemble it into an L-shaped bracket structure, and tighten it with bolts 4 to ensure that the L-shape of the bracket itself has good verticality; wherein, the auxiliary alignment device 9 is a horizontal bar with a U-shaped clamping position at one end, and the U The size of the U-shaped clamping position matches the outer diameter of the vertical bar, and the U-shaped clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com