Underground embedded steel column straightening limiting device

A technology of limit device and steel column, which is applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of low construction precision, large material loss, and low construction efficiency, and achieve easy operation, stable structure, and improved construction efficiency. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

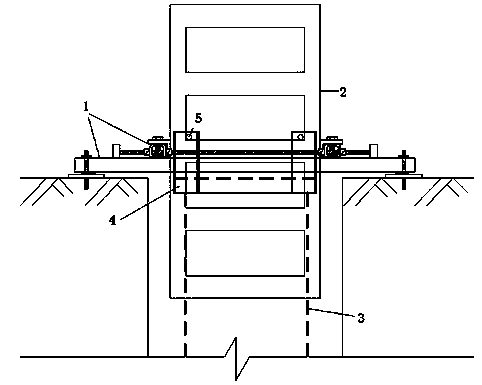

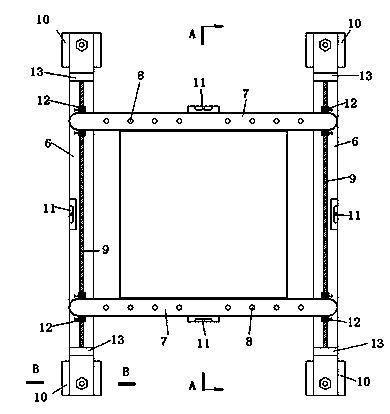

[0022] like Figure 1 to Figure 8 As shown, the underground embedded steel column straightening and limiting device of the present invention includes a horizontal adjustment bracket 1, a vertical guide cylinder 2, an underground embedded steel column 3, and the like.

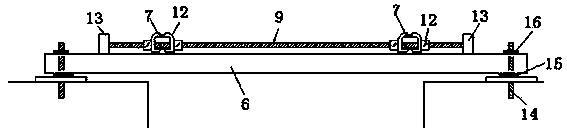

[0023] like figure 1 As shown, the vertical guide cylinder 2 is placed on the horizontal adjustment bracket 1 that has been adjusted to the level, and is positioned and connected with the horizontal adjustment bracket 1 with the limit latch 19 ( Figure 7 ); the vertical guide tube 2 silo is hoisted into the underground pre-embedded steel column 3 provided with guide hanging bars 4 ( Figure 8 ), and fix the underground pre-embedded steel column 3 on the vertical guide tube 2 with a shoulder pole 5 .

[0024] like Figure 2 to Figure 5 As shown, the horizontal adjustment bracket 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com