Quick powder product forming hydraulic press

A hydraulic press and powder technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of affecting production efficiency, inconvenient use, complex demoulding procedures, etc., to improve transportation efficiency, save time and cost, Reduce the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

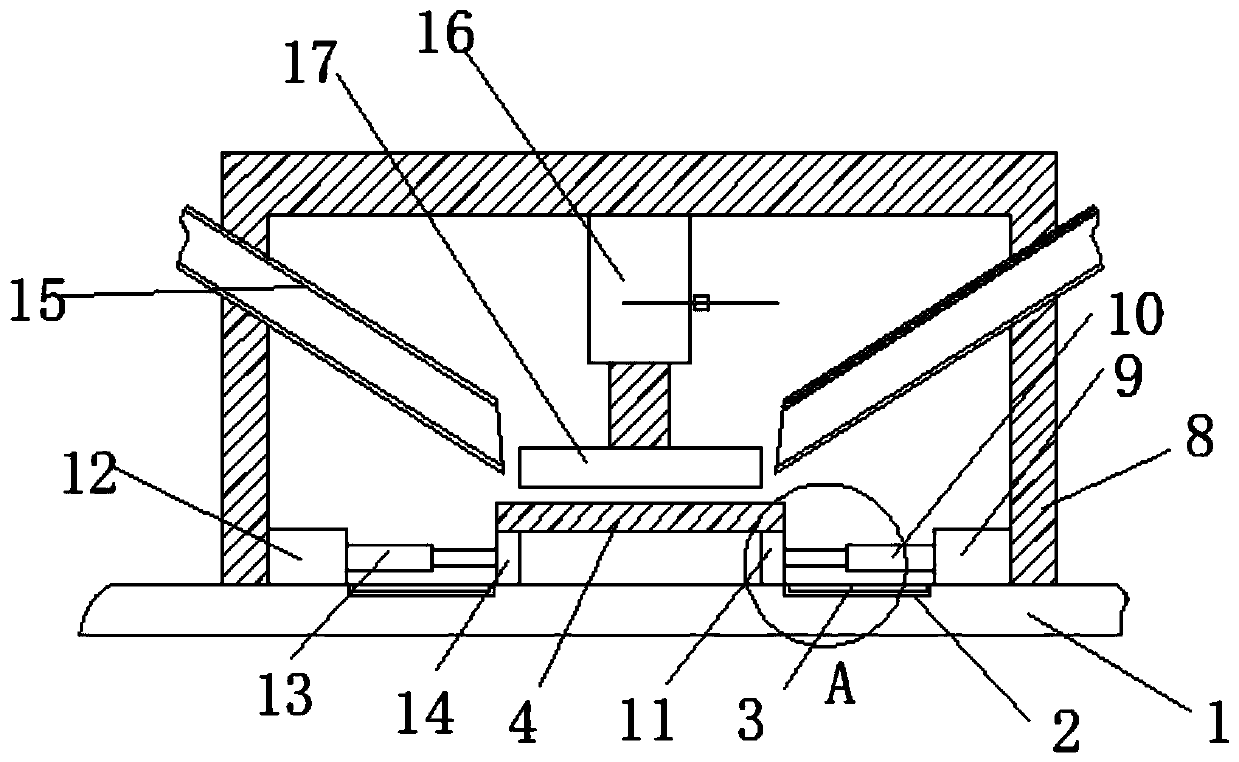

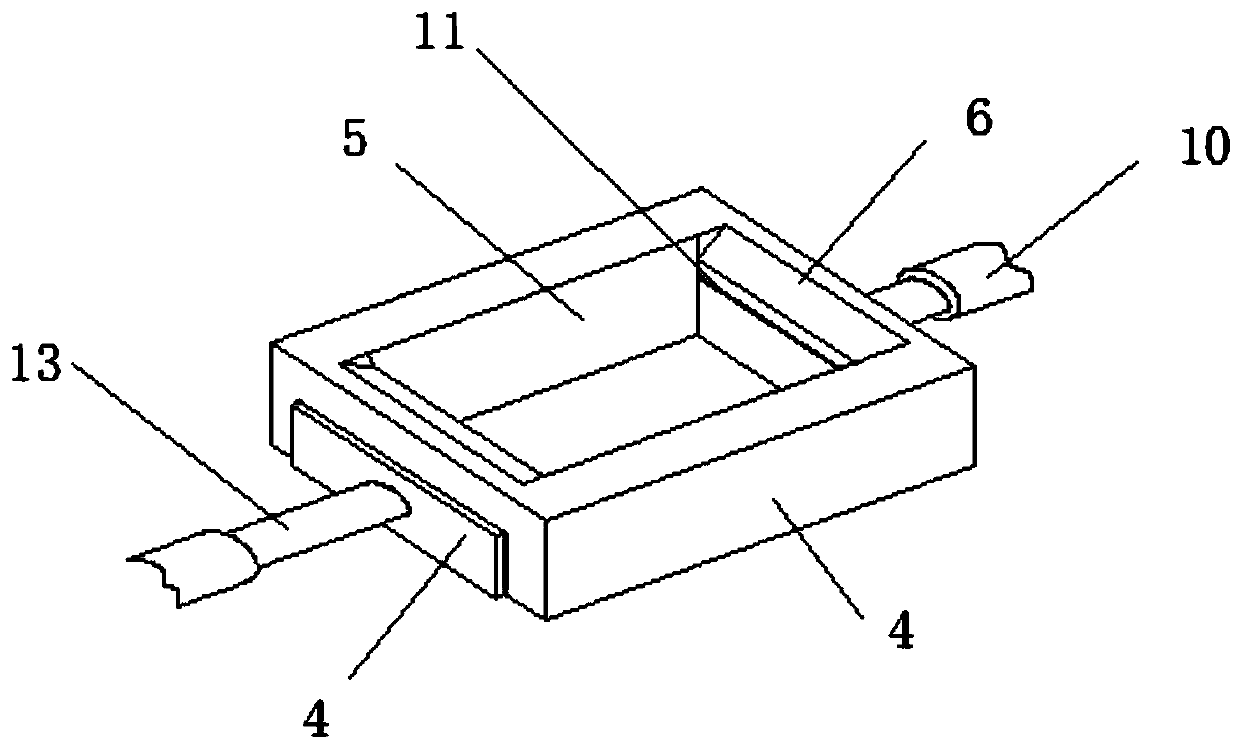

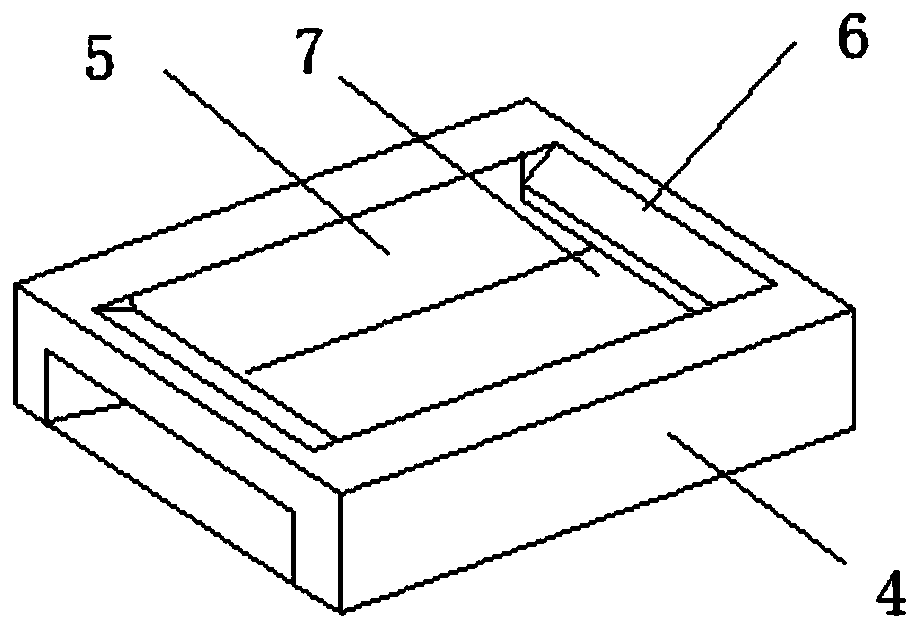

[0024] see Figure 1-4 , the present invention provides a technical solution: a rapid powder product forming hydraulic machine, which includes: a bottom plate 1, a forming mold 4, a mold groove 5, a main pressure rod 16 and a molding plate 17, and symmetrical sliding grooves are arranged on both sides of the bottom plate 1 2. A freely slidable conveyor belt 3 is set in the sliding groove 2, and the forming mold 4 is connected to the bottom plate 1. The forming mold 4 is provided with a mold groove 5, and the upper end of the forming mold 4 is provided with a symmetrically distributed chute 6. The two sides of the forming mold 4 There are die notches 7 symmetrically distributed, the bottom plate 1 is connected with a support rod 8, and one end of the support rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com