Plate intelligent subpackaging method and device

A panel and intelligent technology, applied in the field of panel intelligent subcontracting, can solve problems such as occupancy, low packaging efficiency, and inconsistent subcontracting standards, and achieve the effects of saving filling materials, saving production costs, and improving rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

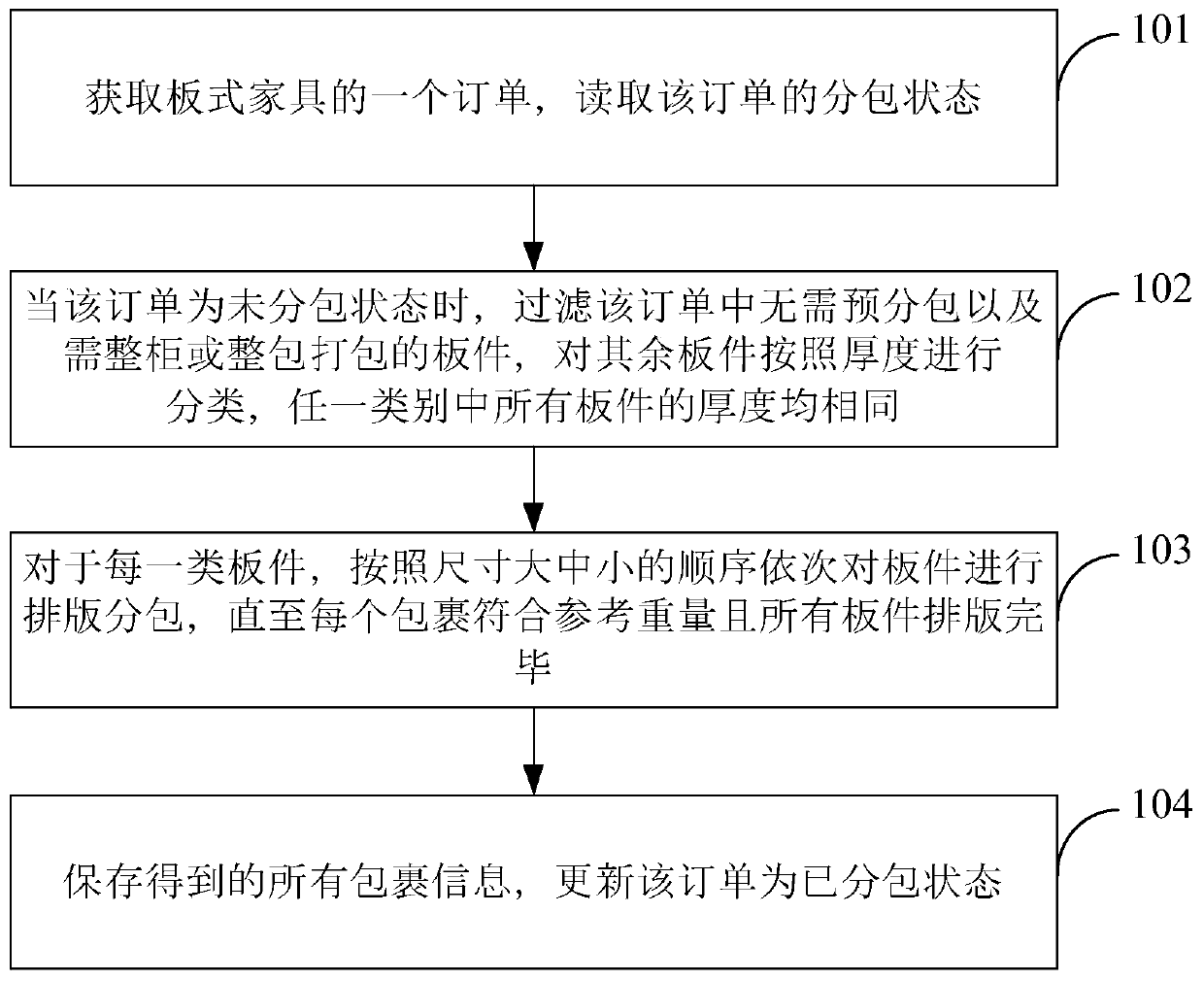

[0056] figure 1 It is a flowchart of a method for intelligent panel subcontracting according to an embodiment of the present application. see figure 1 , the method includes:

[0057] 101: Obtain an order for panel furniture, and read the subcontracting status of the order;

[0058] 102: When the order is not subcontracted, filter the boards that do not need to be pre-subcontracted and that need to be packaged in the whole cabinet or package, and classify the remaining boards according to their thickness. The thickness of all boards in any category are the same;

[0059] 103: For each type of board, typesetting and subpackaging the boards in the order of large, medium and small in size until each package meets the reference weight and all boards are sorted;

[0060] 104: Save all the obtained package information, and update the order to be subcontracted.

[0061] In this embodiment, optionally, for each type of board, typesetting and subpackaging the boards in order of lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com