Underwater engineering conveying belt

An underwater engineering, conveyor belt technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as the inability to work or rest underwater permanently, the traction motor has not been proposed or introduced, and cannot be

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

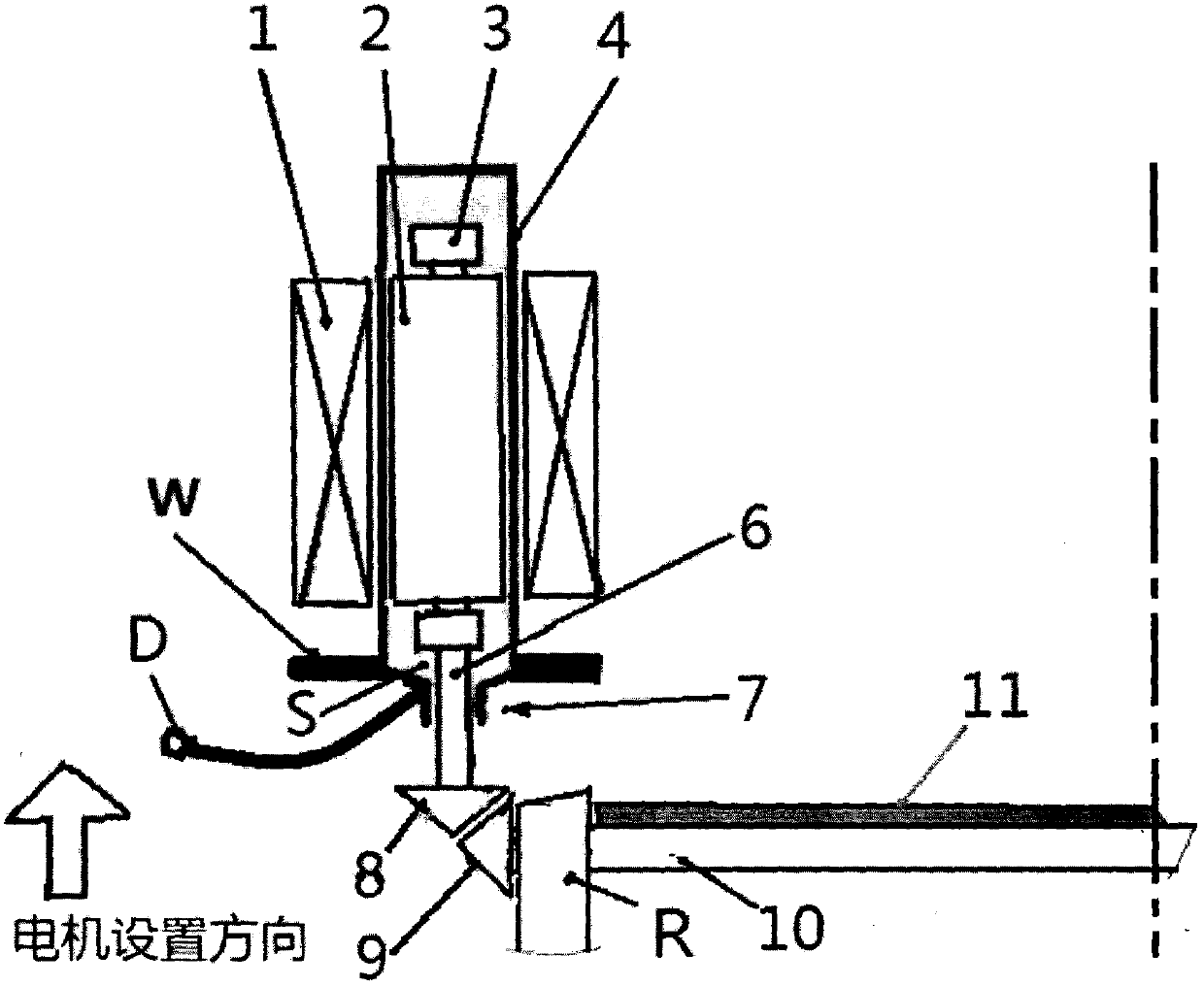

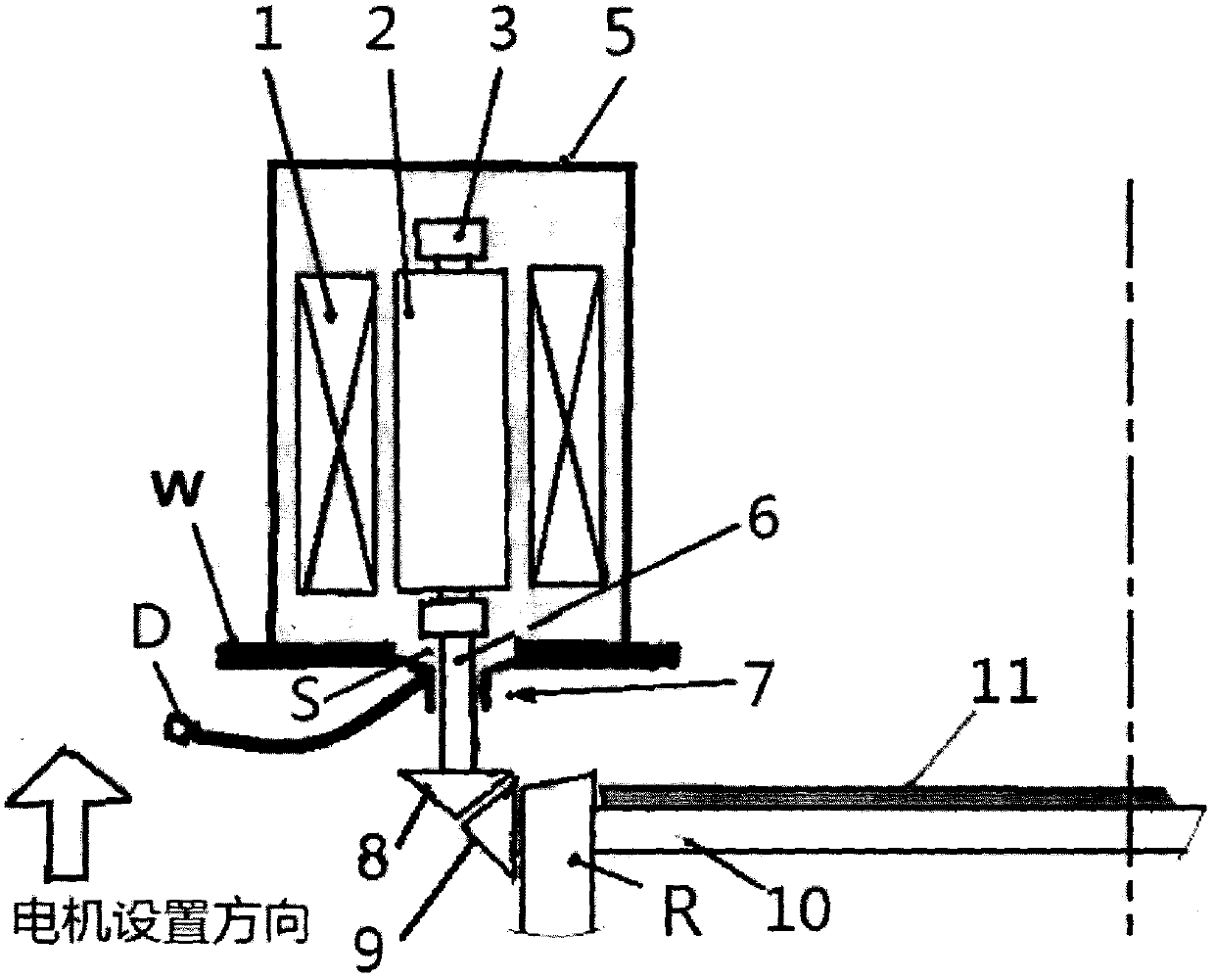

[0024] The present invention is composed of a conveyor belt structure with a support R suitable for being set underwater and a special underwater drag motor:

[0025] 1. Vertical drive (special requirements for underwater drag motors) The horizontal operation of the underwater conveyor belt 11:

[0026] The vertical helical gear 8 connected to the lower end of the vertical rotating shaft 6 and the horizontally rotating end transverse helical gear 9 connected with the horizontal roller 10 driving the horizontal conveyor belt 11 to move forward are driven as a reversing mode of mutual vertical tooth connection.

[0027] 2. The structure of an under-water drag motor:

[0028] Including: a drive motor composed of a rotor 2 and a stator 1 with embedded windings in a conventional structure to implement torque output through its shaft 6;

[0029] Its characteristics are:

[0030] At least let the rotor 2 or the rotor 2 and the stator 1 be surrounded by a narrow metal sealing isolation shield 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com