Infinite dragging motor capable of deep diving

A technology of dragging motors and deep diving, applied in conveyors, electromechanical devices, electrical components, etc., can solve problems such as oil leakage to the outside of plastic bags, inability to work or rest underwater permanently, and inability to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

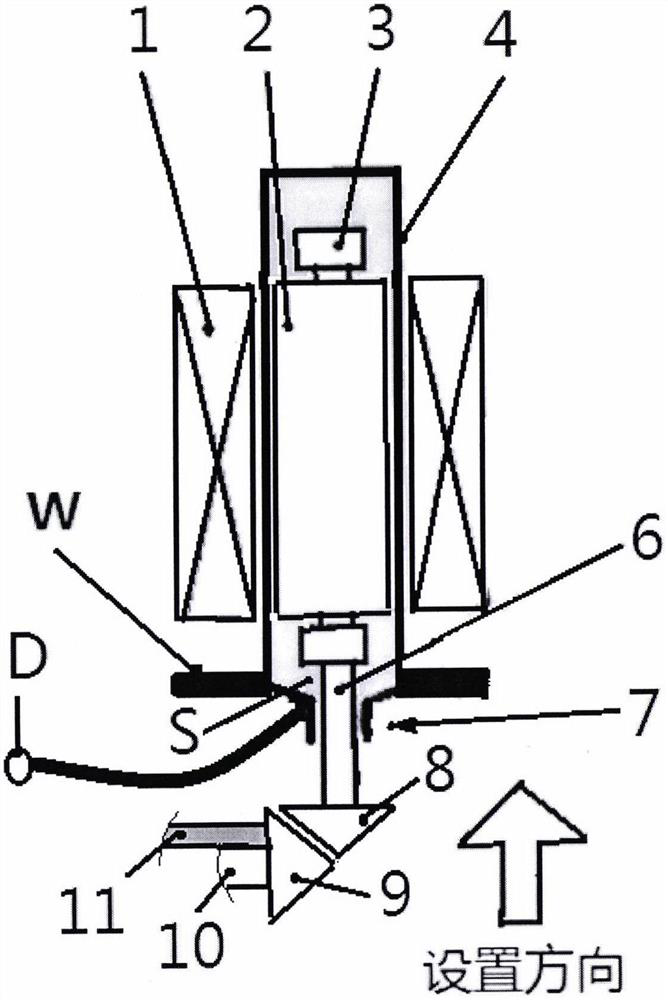

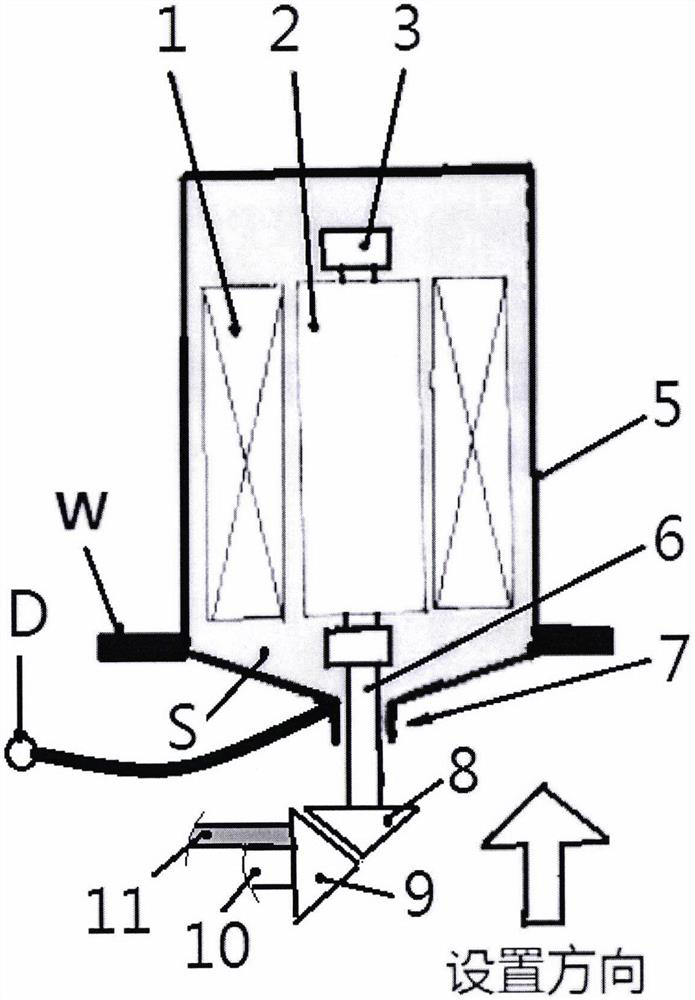

[0023] In order to achieve the purpose of the present invention, you adopt the following technology, which is characterized in that:

[0024] The present invention is a submersible drag motor that is filled with incompressible oil and is composed of a rotor 2 and a stator 1 embedded in a winding, and implements torque output through its rotating shaft 6 that is arranged vertically downward. On the same horizontal plane as the shaft seal position 7 (it can be determined by visual inspection with errors) there is an oil filling nozzle D or an oil filling nozzle D provided through the pipe joint at other places at this position.

[0025] The structure of the present invention is as follows:

[0026] It allows the rotor 2 or the rotor 2 and the stator 1 to be surrounded by a narrow metal-sealed isolation shield 4 or a wide metal-sealed isolation shield 5 in a three-dimensional form, and, in the narrow-type metal-sealed isolation shield 4 or wide-type metal-sealed isolation shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com