A pipe threading device for steel cage

A technology of pipe threading device and steel cage, which is applied in construction, infrastructure engineering, sheet pile wall, etc., can solve the problem of low efficiency of manual pipe threading, save time and labor for pipe threading, prevent collision damage, and realize dismantling. The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

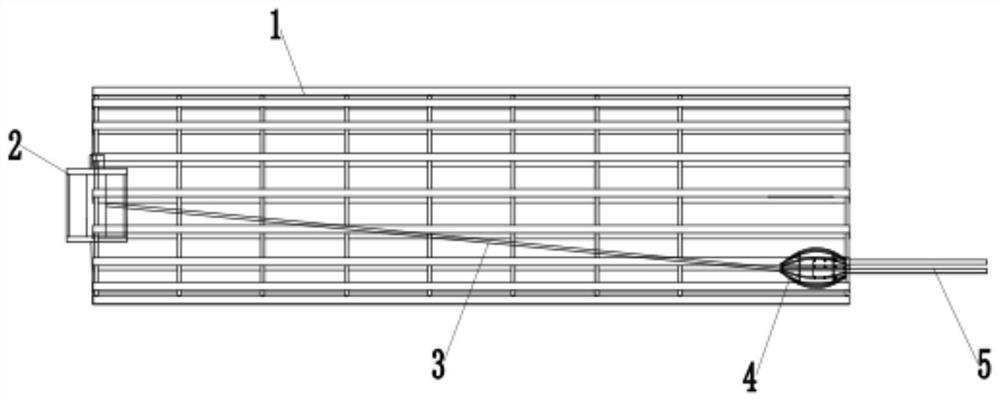

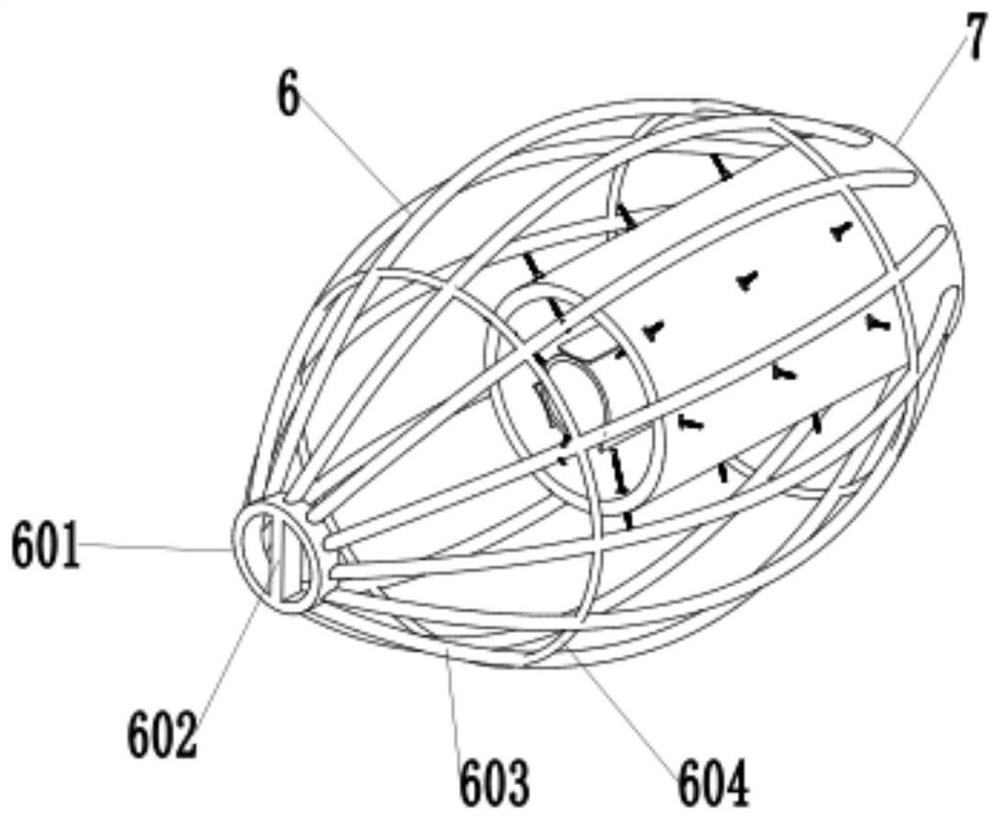

[0032] Such as figure 1 As shown, a pipe threading device for a reinforcement cage includes a guide 4 and a wire take-up device 2 connected to one end of the reinforcement cage 1, and the wire take-up device 2 passes a traction rope 3 Connect with bootstrap 4 like figure 2 As shown, the guide 4 includes a support frame 6 and a clamping device 7. The outer diameter of the support frame 6 gradually increases from both ends to the middle, and one end of the support frame 6 is connected with the traction rope 3, and the support frame 6 The other end is connected with a clamping device 7 , and the clamping device 7 is arranged in the support frame 6 .

[0033] Such as figure 1 As shown, a plurality of pipes are clamped and fixed at the same time by the clamping device 7, the staff pulls the end of the traction rope and connects it with the guider, and pulls the pipes by winding the traction rope 3 through the wire take-up device 2. Under the premise of the pipe, the automatic p...

Embodiment 2

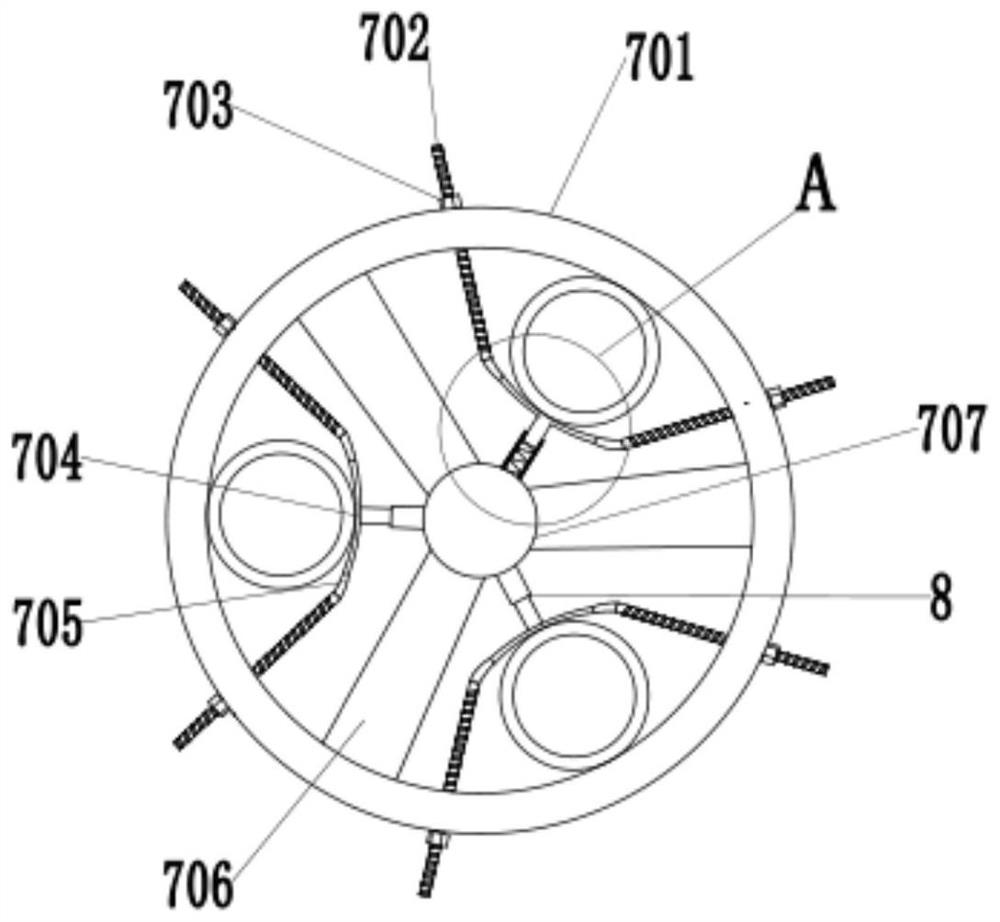

[0042] In order to increase the convenience of installing the pipe into the guide, such as image 3 , 4 As shown, the middle part of the clamp tube 701 is provided with a mounting column 707, the side wall of the mounting column 707 is connected to the inner wall of the clamp tube 701 through a connecting rod 706, and the mounting column 707 is connected to the pressure tube arc plate 704 A puller device 8 is provided between them.

[0043] The puller device 8 includes a puller 801, a spring 802, and a pull rod 803. One end of the puller 801 is connected to the mounting column 707, and the other end of the puller 801 is set on the puller 803. The puller 801 is provided with Spring 802, one end of the spring 802 is connected to the mounting column 707, the other end of the spring 802 is connected to the pull rod 803, and the end of the pull rod 803 away from the spring 802 is connected to the pressure tube arc plate 704, the pull plate device 8 is simple in structure and low i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com