Waste incineration power generation safety monitoring system

A safety monitoring system and waste incineration technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as endangering the personal safety of workers and endangering their own safety, so as to improve safety, reduce the possibility of accidents, and improve The effect of safe processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

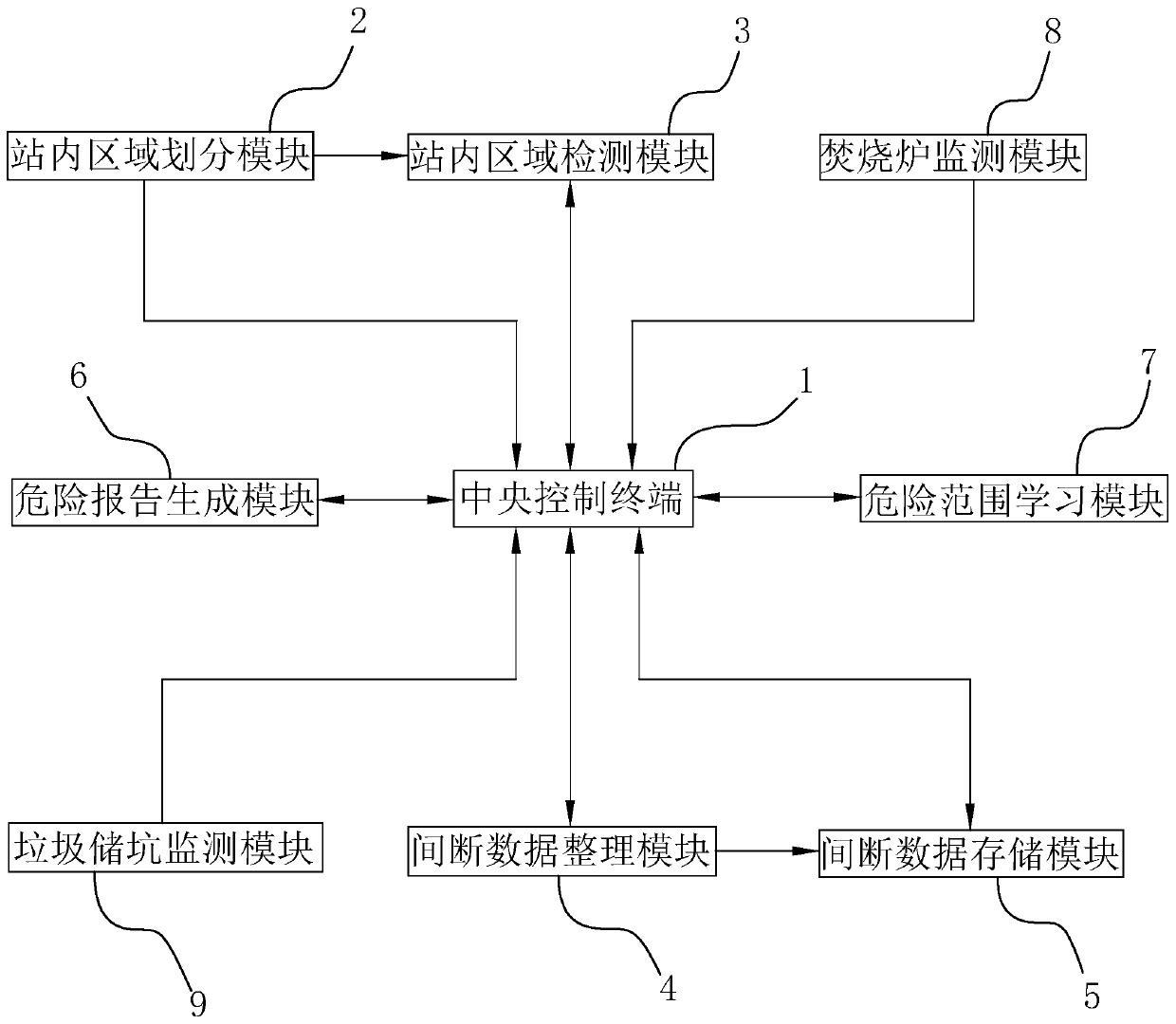

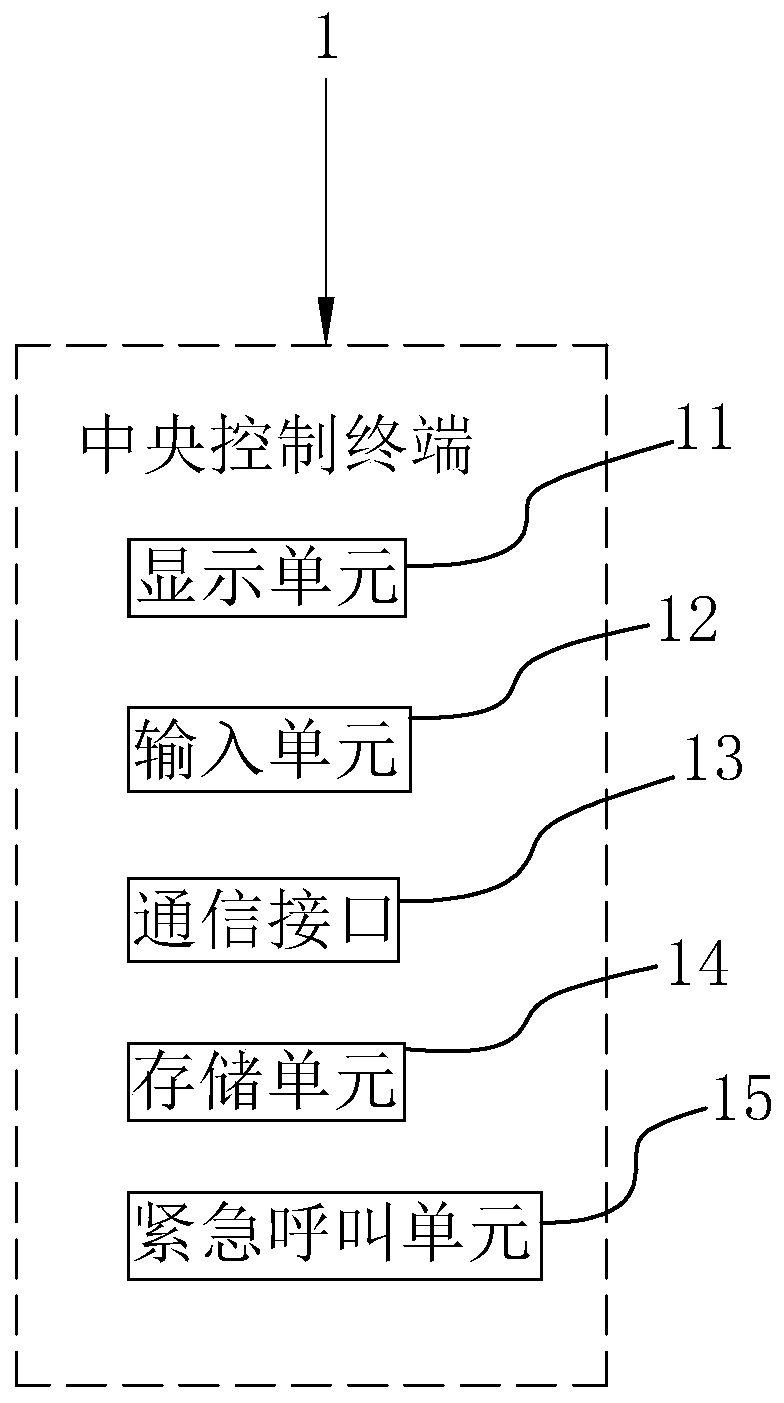

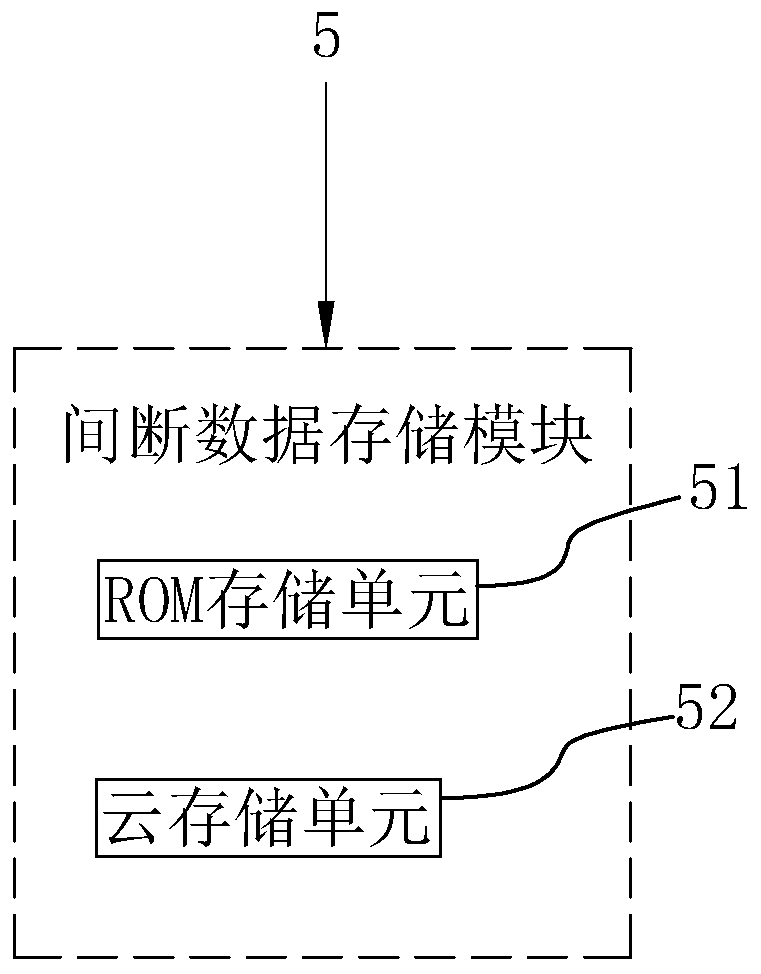

[0059] Embodiment: a kind of waste incineration power generation safety monitoring system, such as figure 1 and figure 2 As shown, it includes the station area division module 2, the station area detection module 3, the garbage storage pit monitoring module 9, the incinerator monitoring module 8, the intermittent data sorting module 4, the intermittent data storage module 5, the danger report generation module 6 and the danger range learning The module 7 also includes a central control terminal 1 installed in the waste incineration power station. In-station area division module 2, in-station area detection module 3, garbage storage pit monitoring module 9, incinerator monitoring module 8, intermittent data sorting module 4, intermittent data storage module 5, hazard report generation module 6 and hazard range learning module 7 are all set In the central control terminal 1. The central control terminal 1 includes a display unit 11 , an input unit 12 , a communication interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com