Mixed masonry method forrefractory material protective lining on outer side of hanging cylinder block

A technology of hanging cylinders and protective linings, applied in the direction of lining support, lining repair, etc., can solve the problems of easy falling off of bricks, large masonry errors, large thermal expansion and deformation, etc., to simplify the masonry process, reduce errors, and avoid loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

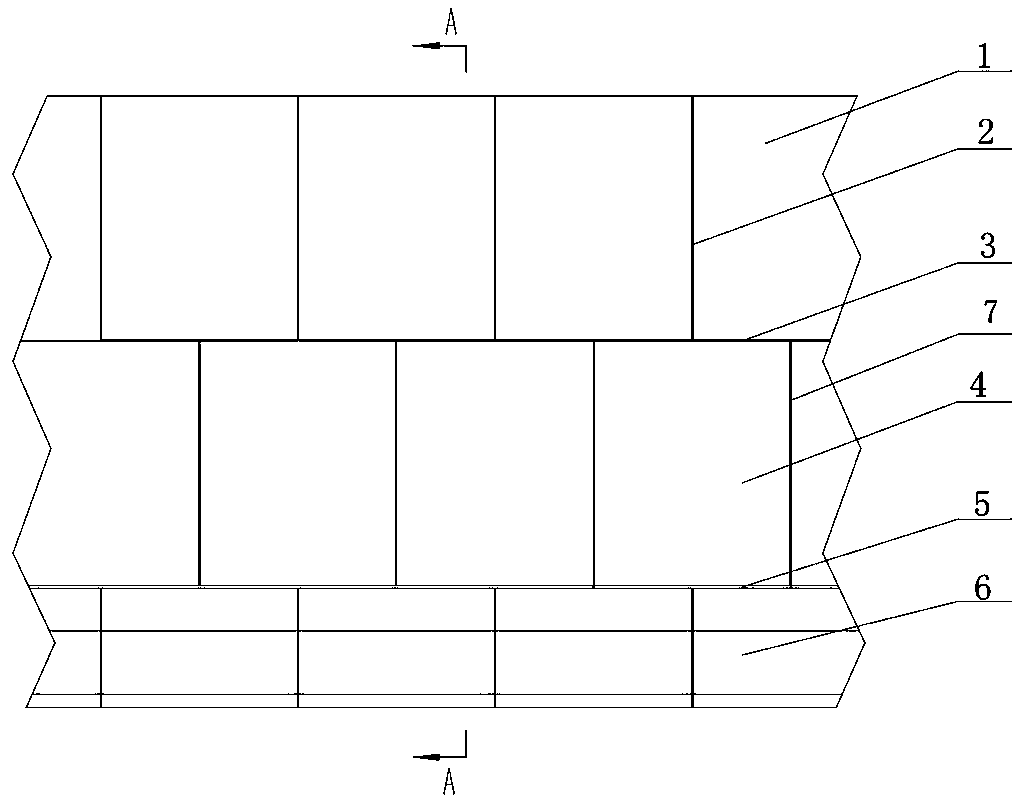

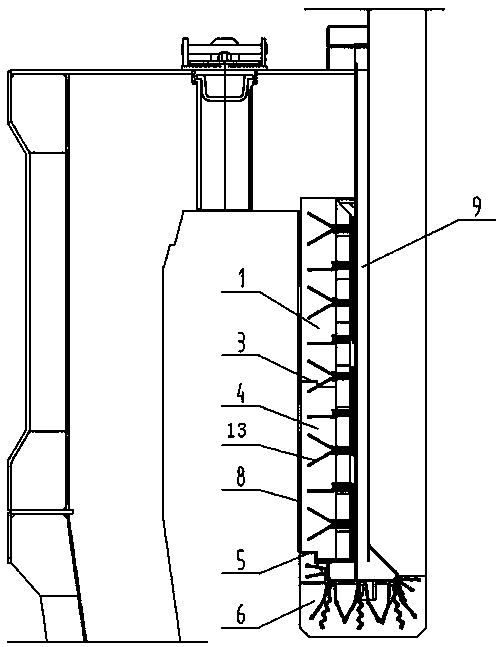

[0031] Refer to attached figure 1 , 2 , before pouring the lower castable material 4, pour a layer of bottom castable material 6 at the bottom of the suspension cylinder body 9 as a support, and lay a layer of refractory ceramic fiber board 3 with a thickness of 12mm on the top of the bottom castable material 6 ; Then utilize the steel mold 10 to cast the lower castable 4 block by block on the circumferential direction outside the suspension cylinder block 9 .

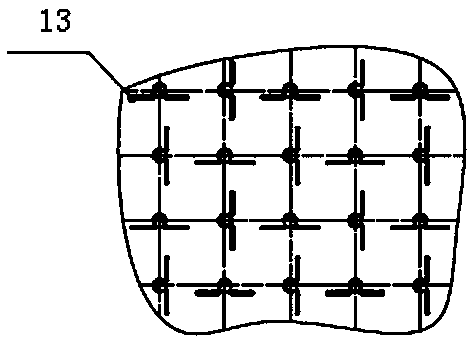

[0032] Refer to attached Figure 5 , 6 , 7. The profile of the cross section of the steel mold is a fan shape matched with the suspension cylinder body 9, one side of the fan shape is provided with a groove 11, and the other side of the fan shape is provided with a protrusion matching the groove 11 12. The grooves 11 and protrusions 12 on the steel mold 10 can make the bite between two adjacent castables stronger after pouring and prevent them from falling off after being heated and expanded.

[0033] Refer to att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com