Shipborne supervision and rescue terminal

A terminal and ship-borne technology, applied in the field of ship supervision and rescue integrated devices, can solve the problems of high maintenance cost, small space, occupying ships, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

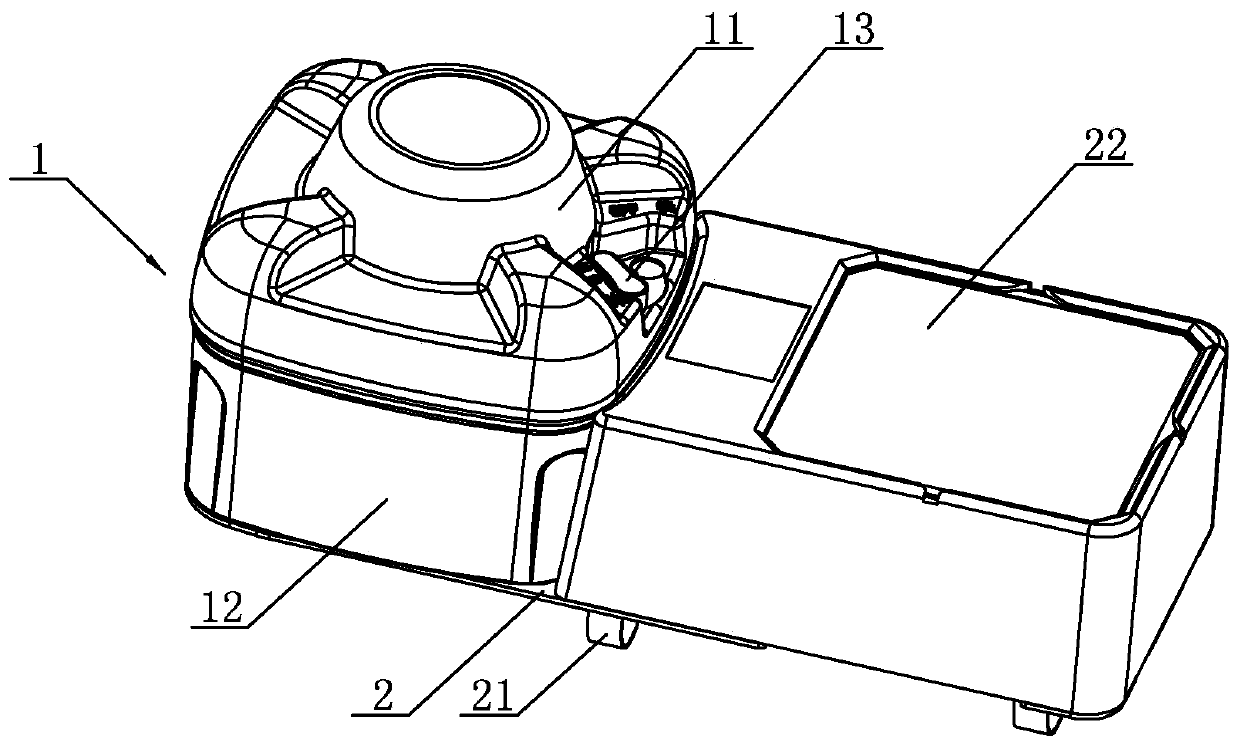

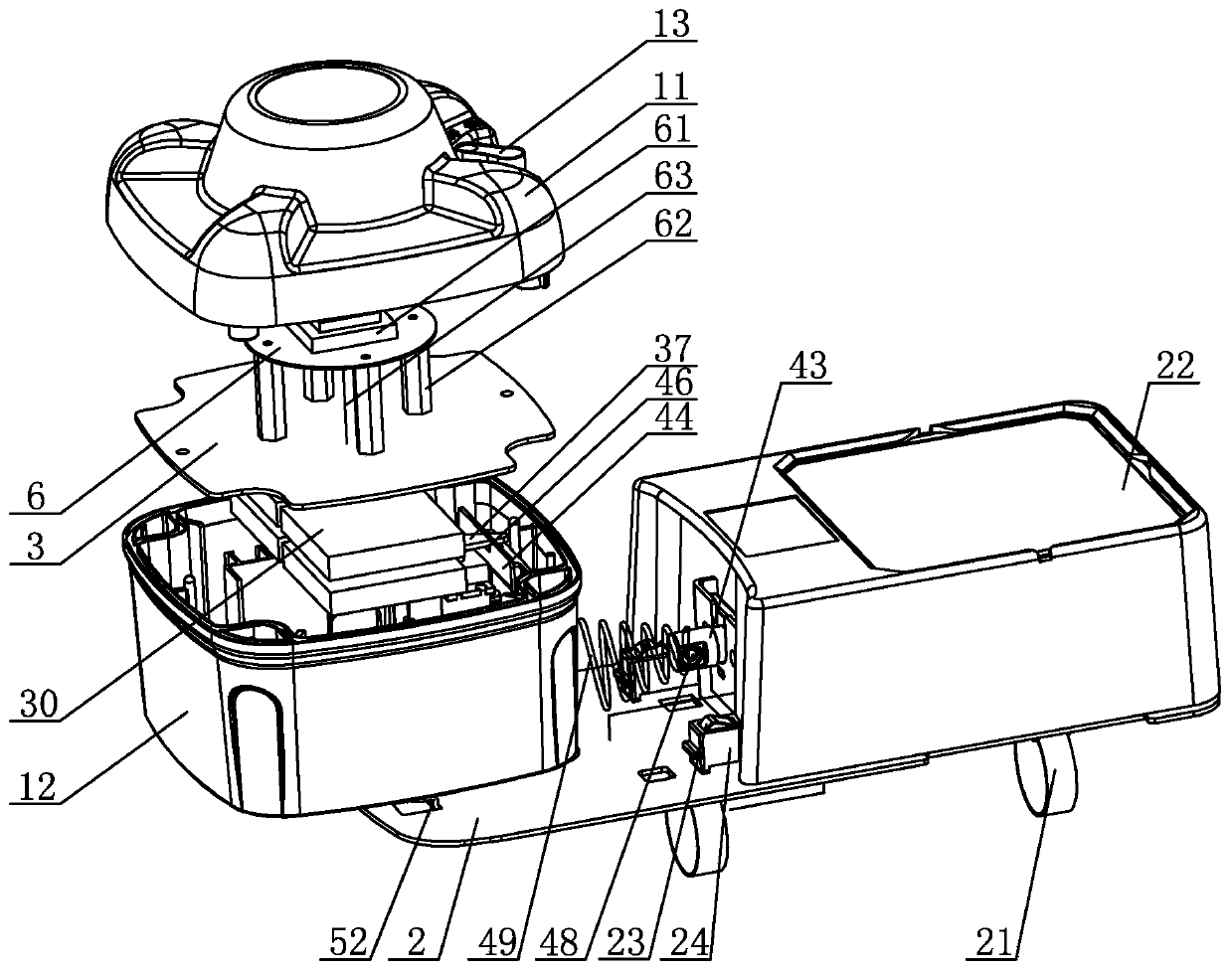

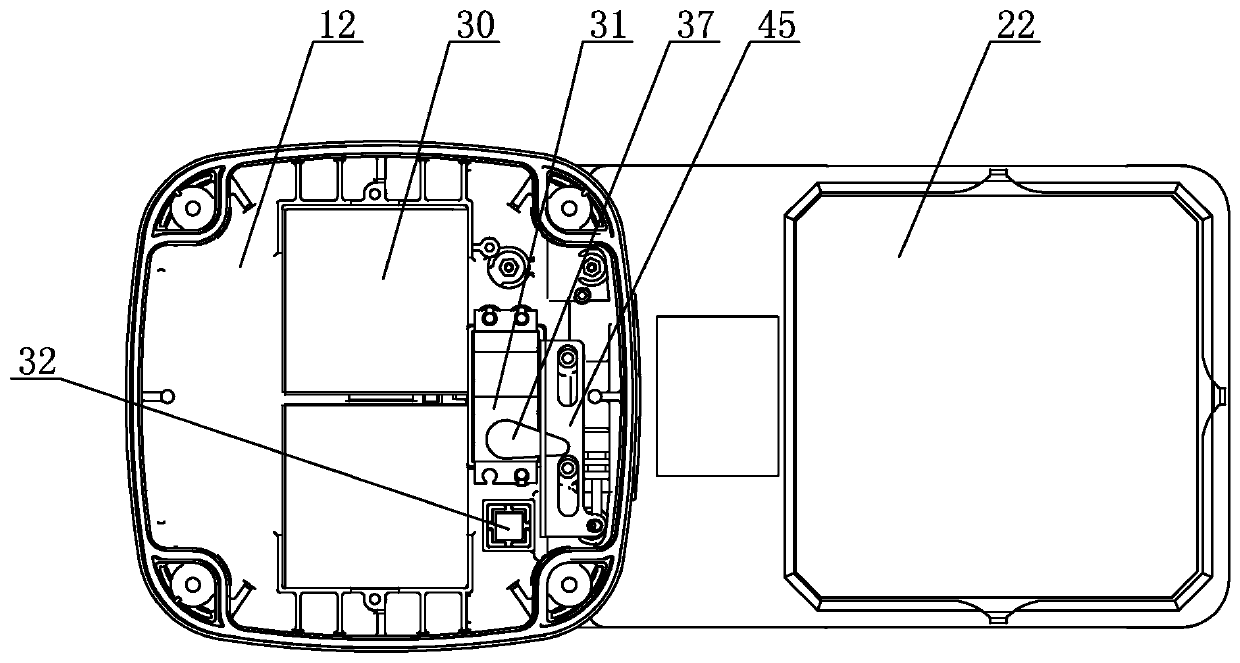

[0025] The ship-borne supervision and rescue terminal of embodiment 1, as shown in the figure, includes a buoy 1 and a sheet metal base 2, the buoy 1 includes an upper cover 11 and a bottom shell 12, and two hoops 21 are installed on the bottom surface of the sheet metal base 2, and the sheet metal base 2 The gold base 2 is installed on the railing or mast of the ship through two hoops 21. A magnetic emergency lever 13 is installed on the outside of the upper cover 11. The upper cover 11 is fixed on the bottom shell 12. The upper cover 11 and the bottom shell 12 A sealed cavity 14 is formed, and a main circuit board 3, a battery 30, a steering gear 31 and a water pressure sensor 32 are installed in the cavity 14, the main circuit board 3 is powered by the battery 30, and an MCU unit is arranged on the main circuit board 3 33, GPS antenna 34, GPS module 35 and GPRS module 36, MCU unit 33 is electrically connected with GPS module 35 and GPRS module 36 respectively, GPS antenna 34...

Embodiment 2

[0027] The difference between the ship-borne supervision and rescue terminal in Embodiment 2 and Embodiment 1 is that in Embodiment 2, a clamping mechanism is provided between the bottom case 12 and the sheet metal base 2, and the clamping mechanism includes a metal strip 51 and two pieces of cards. The tightening piece 52 and the metal strip 51 are fixed on the side of the bottom surface of the bottom shell 12 away from the trip plate 43, and the two clamping pieces 52 are respectively fixed on the sheet metal base 2, and the bottom surface of the bottom shell 12 is provided with two positioning slots 19. The two positioning grooves 19 are respectively arranged on one side of the metal strip 51, and the side of each positioning groove 19 away from the metal strip 51 is a slanted groove 10, and the two clamping pieces 52 are respectively limited in the two positioning grooves 19 And hook on the metal bar 51.

Embodiment 3

[0028] The difference between the ship-borne supervision and rescue terminal of Embodiment 3 and Embodiment 1 is that in Embodiment 3, a Beidou board 6 is installed in the cavity 14, and the Beidou board 6 and the main circuit board 3 are connected by studs 62 and pin headers. 63 for physical and electrical connection, the Beidou board 6 is equipped with a Beidou antenna 61 and a Beidou module (not shown in the figure), the Beidou module is electrically connected to the MCU unit 33, and in an environment without GPRS signals, the MCU unit 33 activates the Beidou module , and send the data packet to the remote control center through the Beidou network.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com