IC (integrated circuit) turning mechanism for fully-automatic COG (Chip On Glass) bonder

A technology of flipping mechanism and bonding machine, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of wasting manpower, small freedom of movement, wasting time, etc., to avoid low efficiency, avoid large errors, Precise flip and take over effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

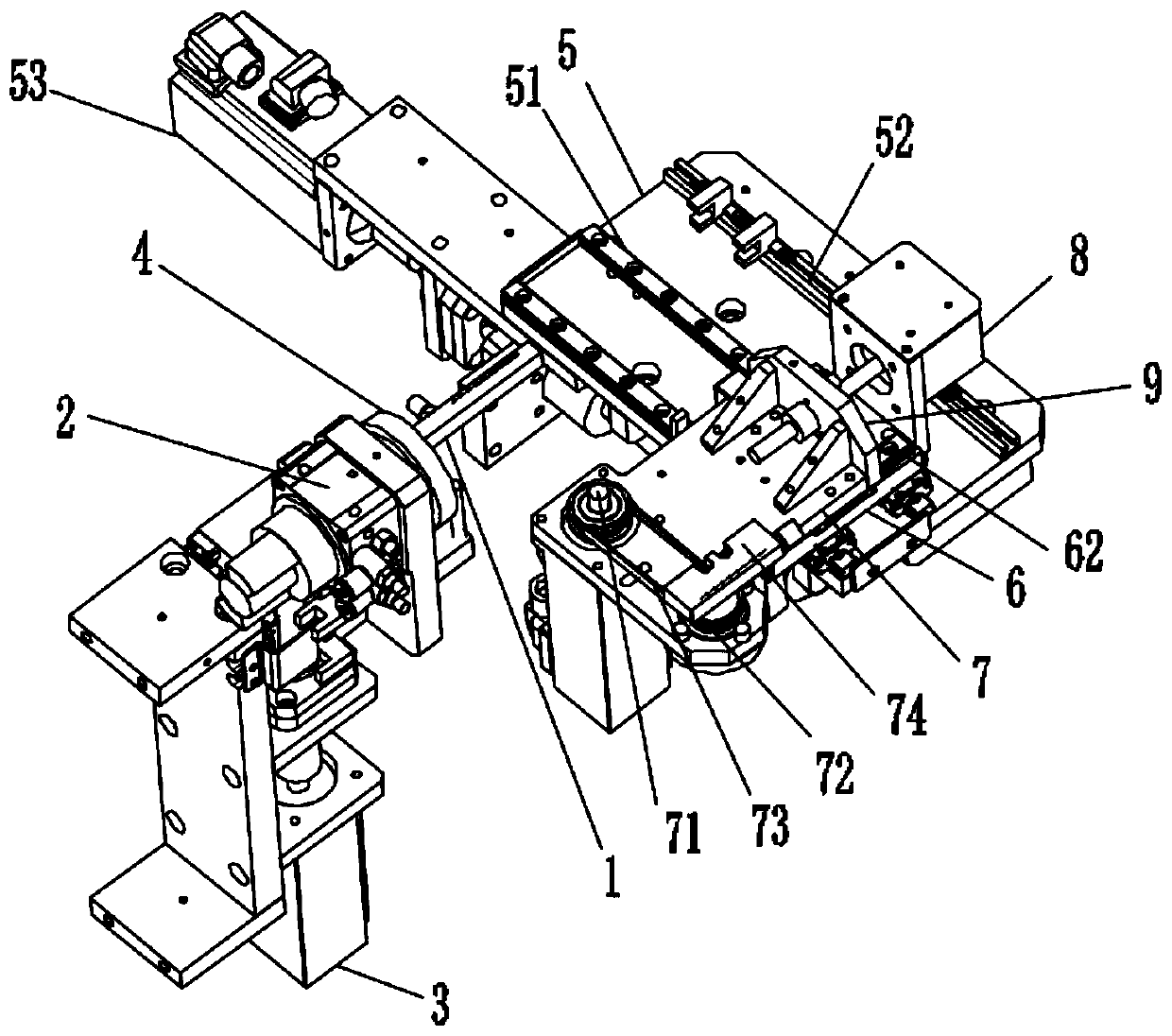

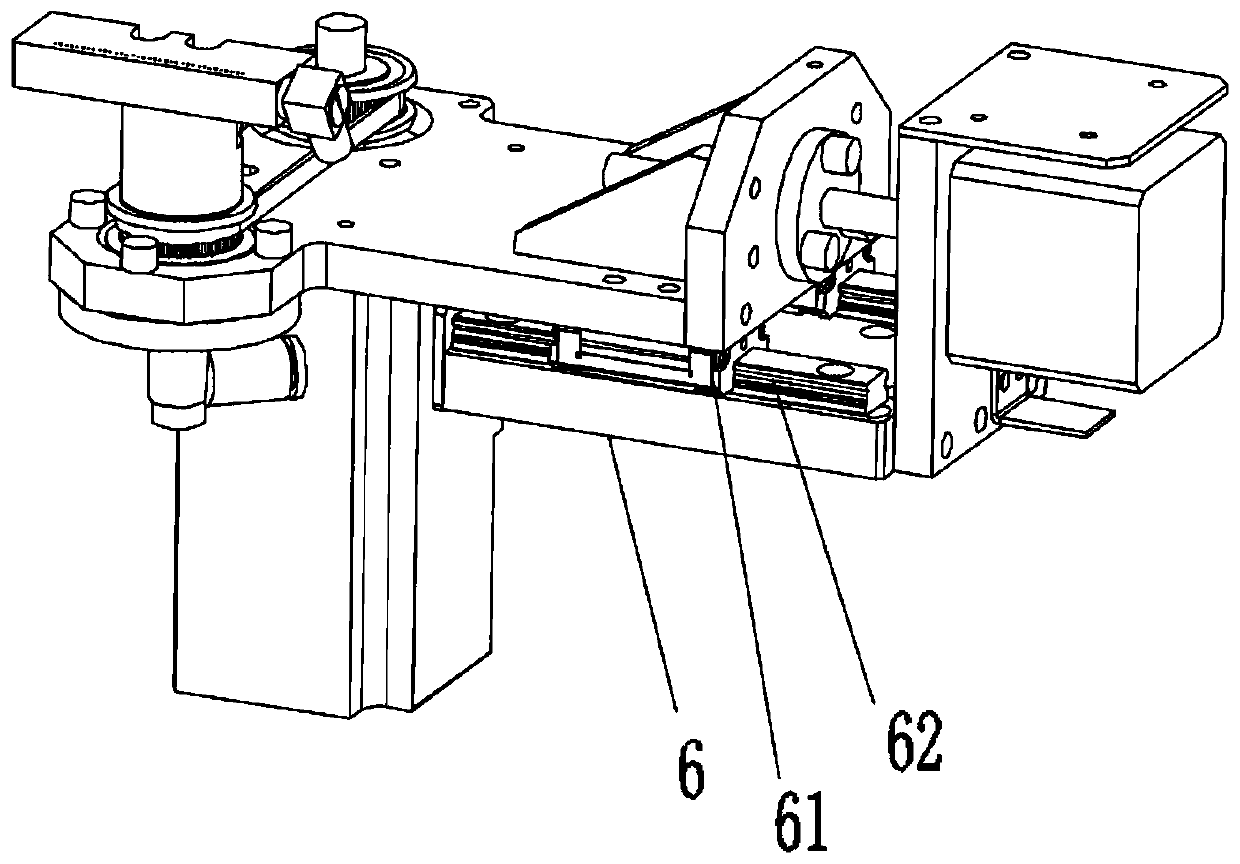

[0022] like figure 1 and figure 2 As shown, a fully automatic COG bonding machine IC flipping mechanism of the present invention includes a flipping part and a bearing part; the flipping part includes:

[0023] Turning platform 1, turning platform 1 is fixed on a rotary cylinder 2 that can drive turning platform 1 to rotate, and the rotation axis of turning platform 1 faces the horizontal direction and is located in the same plane with turning platform 1;

[0024] The speed valve can control the turning speed.

[0025] The connection mode of rotary cylinder 2 and turning platform 1 can be like this: turning platform 1 is vertically and eccentrically fixed on a circular rotating plate 4, and rotating cylinder 2 drives rotating plate 4 to rotate by force transmission element (rotating 4 plates go around a circle The center rotates, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com