Stress reducing thread form

A thread and thread surface technology, applied in threaded connections, threaded fasteners, bolts, etc., can solve problems such as loose connections, failures, and thread interface failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

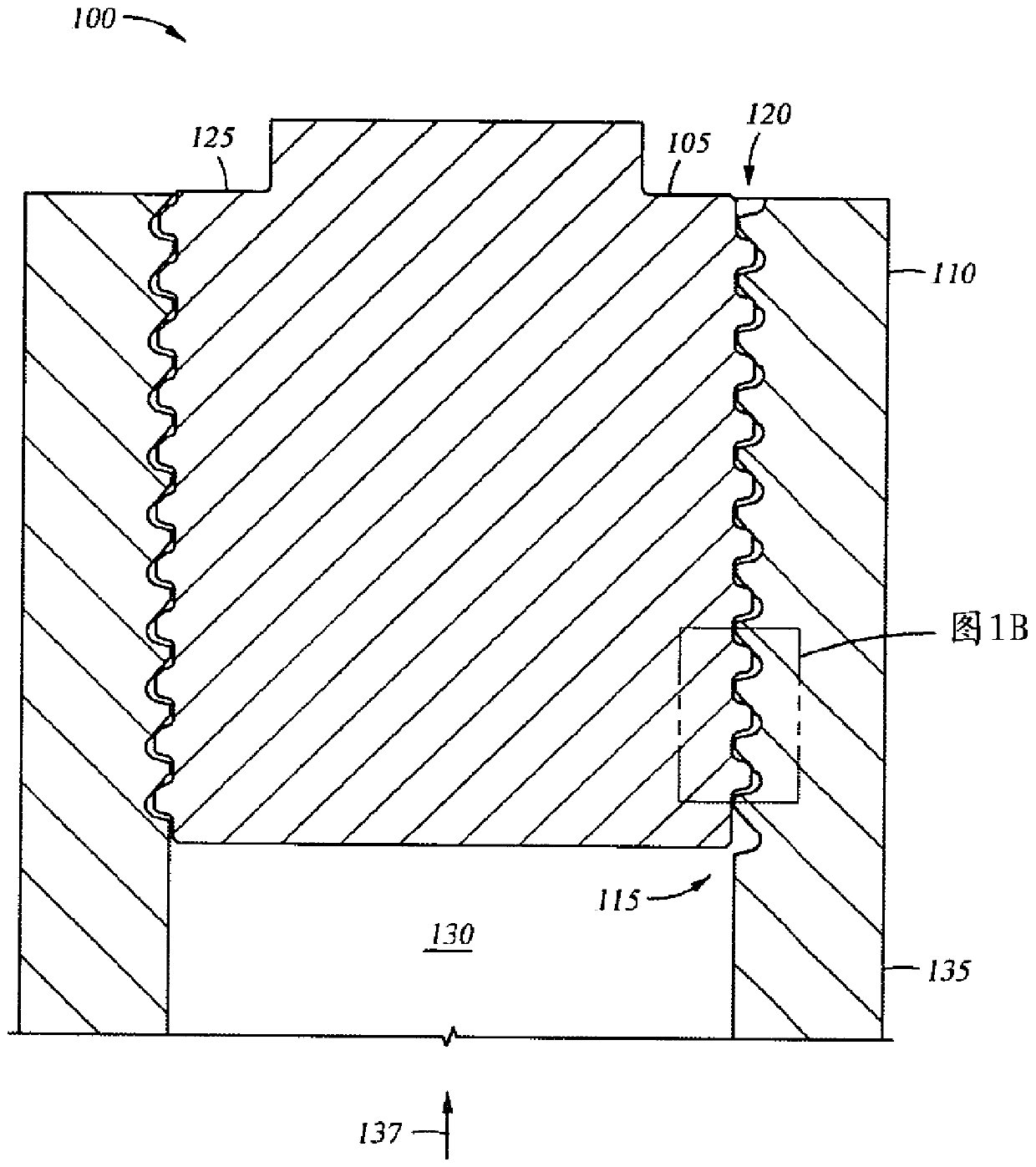

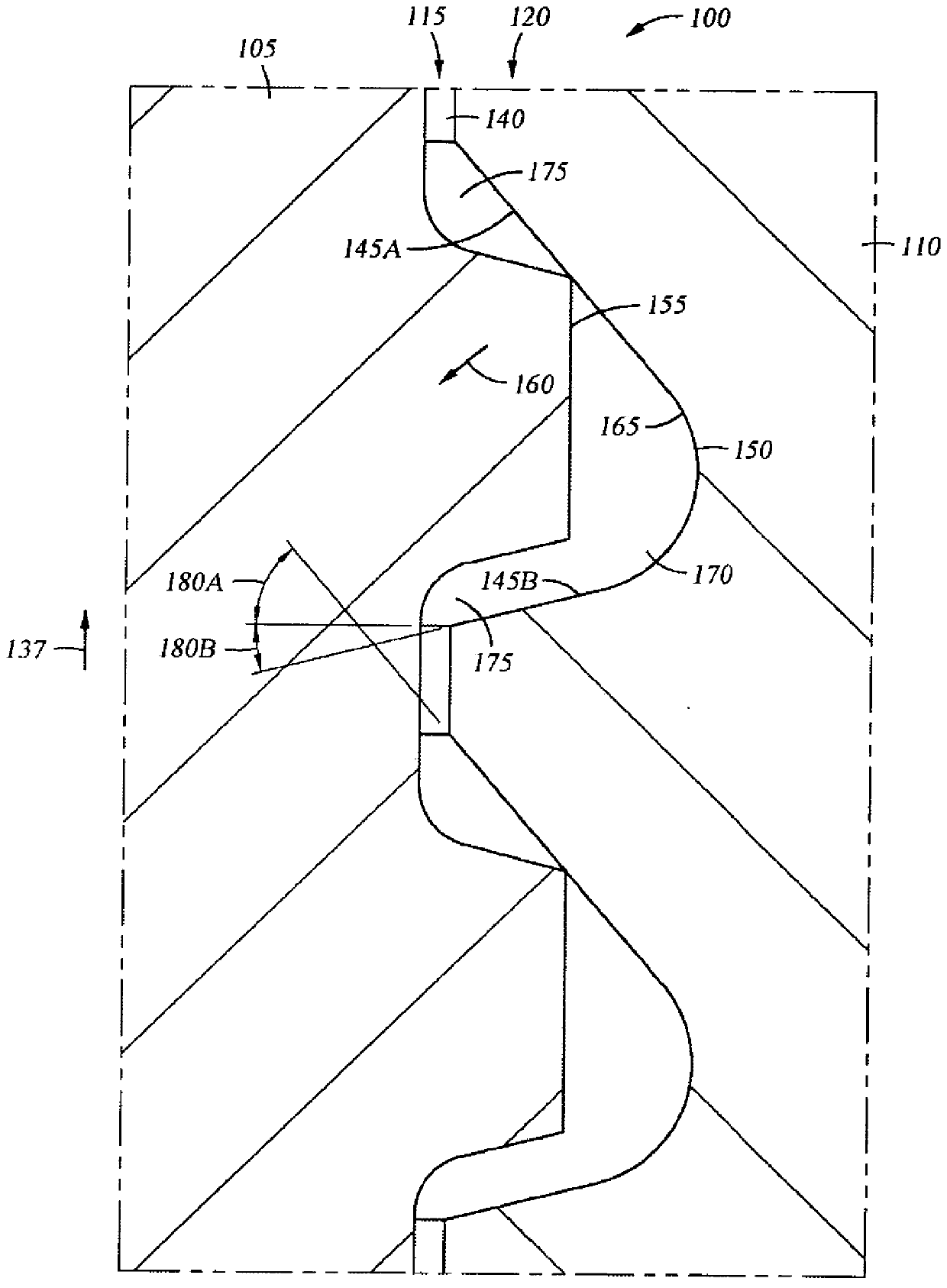

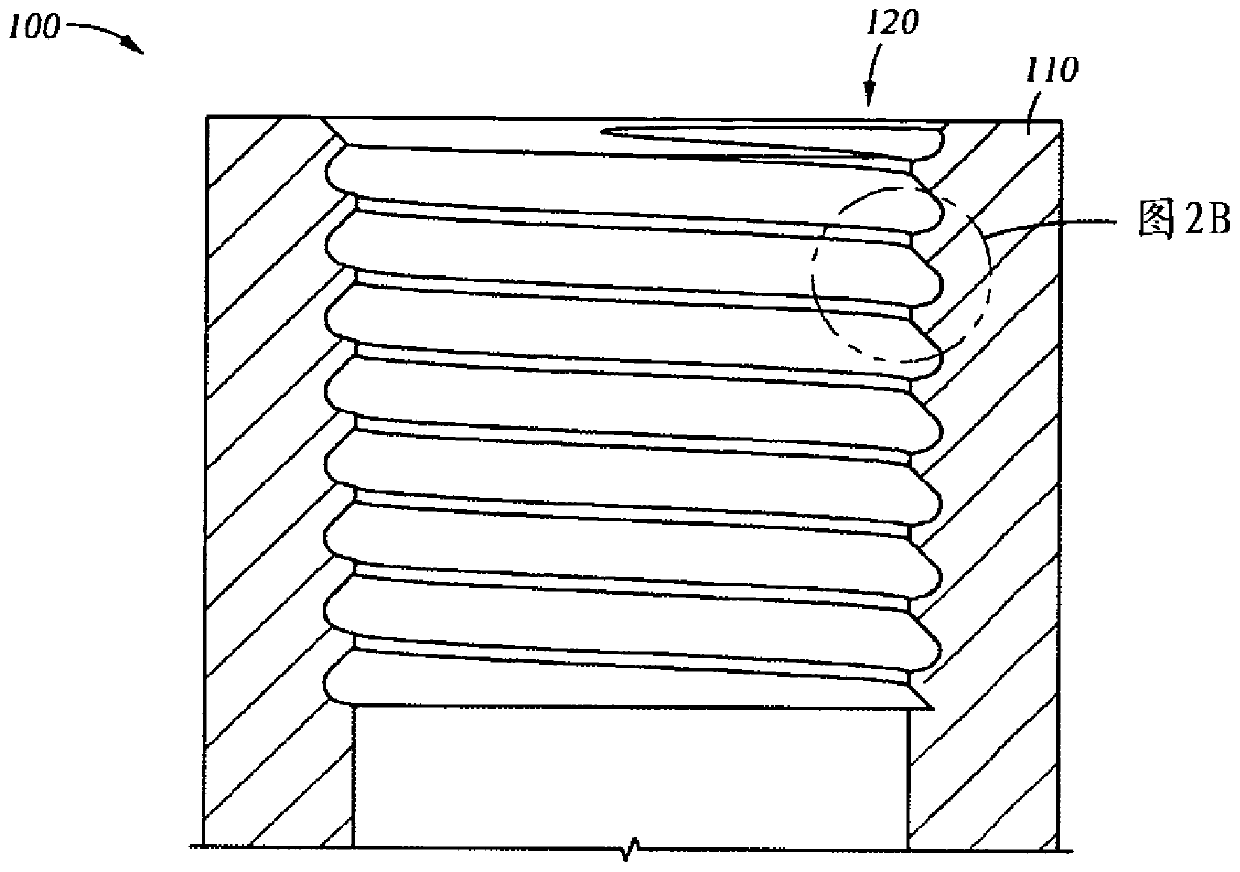

[0013] Embodiments of the present disclosure overcome disadvantages of conventional threaded connections. In conventional threaded connections, the male and female threads are identical or similar in structure, which generates large shear stresses along the longitudinal axis of the threaded connection when subjected to cyclic tension. This high shear stress often causes the threaded connection to fail at the root of the thread upon fatigue. Additionally, the male and female thread structures of conventional threaded connections fit tightly together, which results in galling and / or hydrolocking.

[0014] Embodiments of the present disclosure include stress relief threading. Embodiments of the present disclosure include threaded structures with improved fatigue life that can be used in cyclic loading situations, such as high pressure reciprocating pumps used in the oil and gas industry. Embodiments of the present disclosure include a threaded connection that includes a male th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com