Sheet metal locking cover for a cam phaser

A technology of cam phaser and locking cover, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of large cam phaser, high manufacturing cost, and reducing the strength of the locking cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

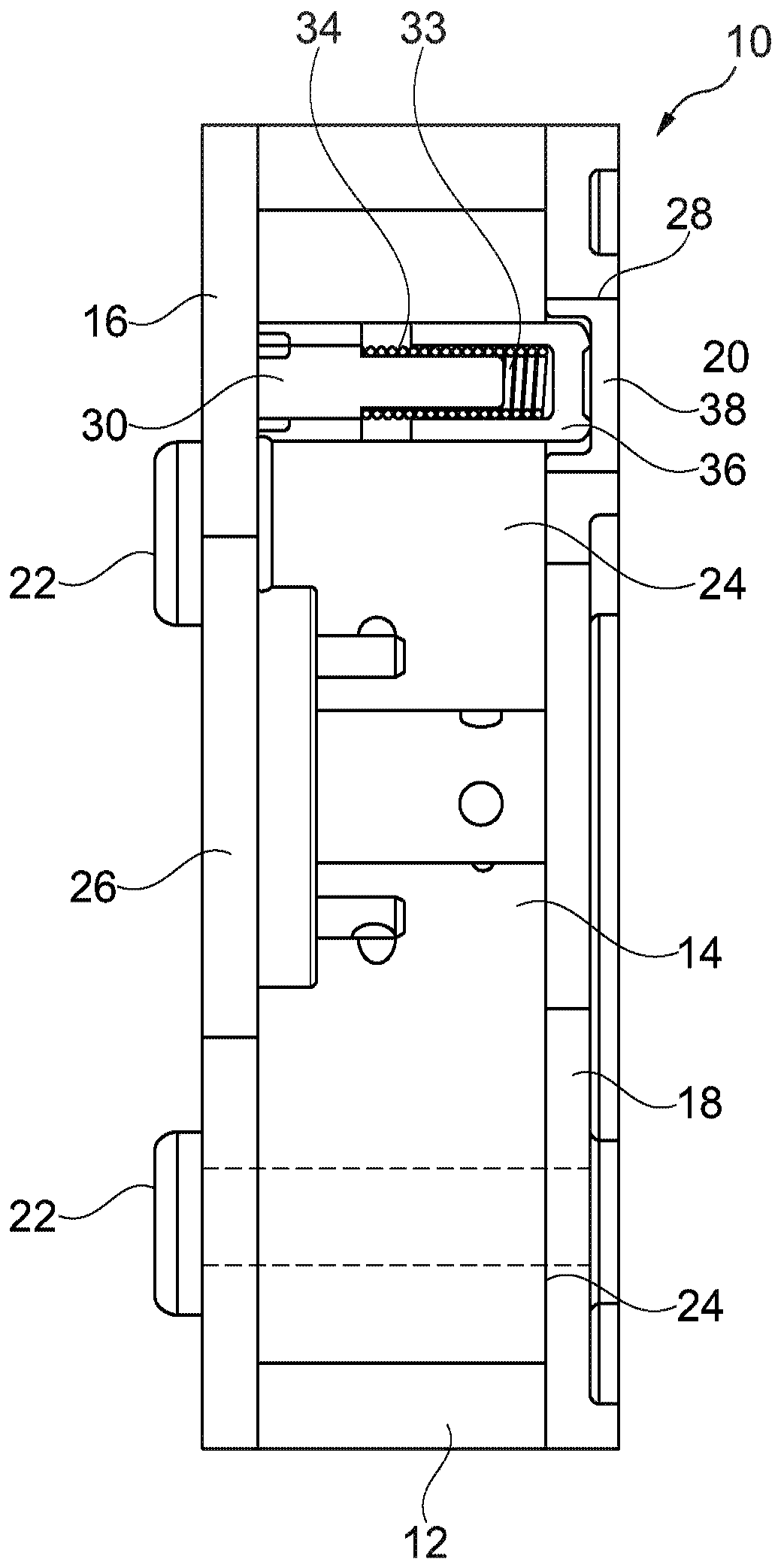

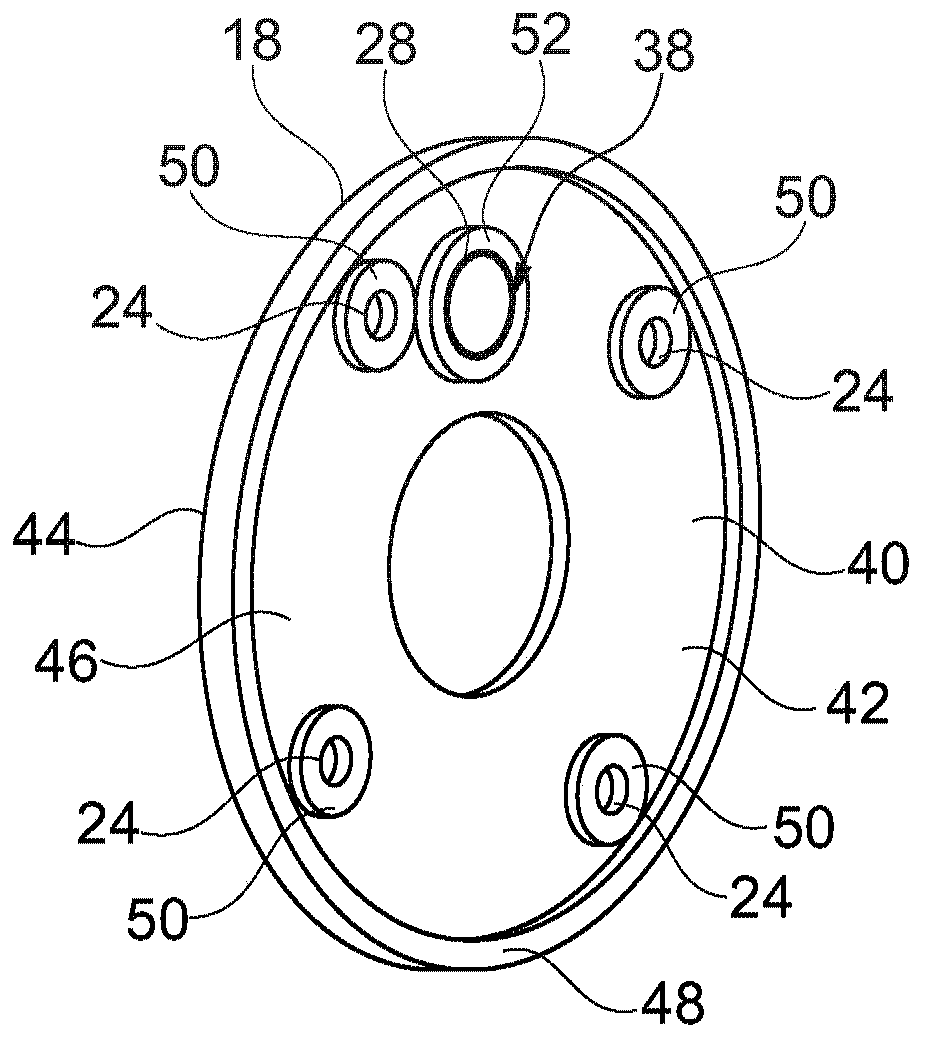

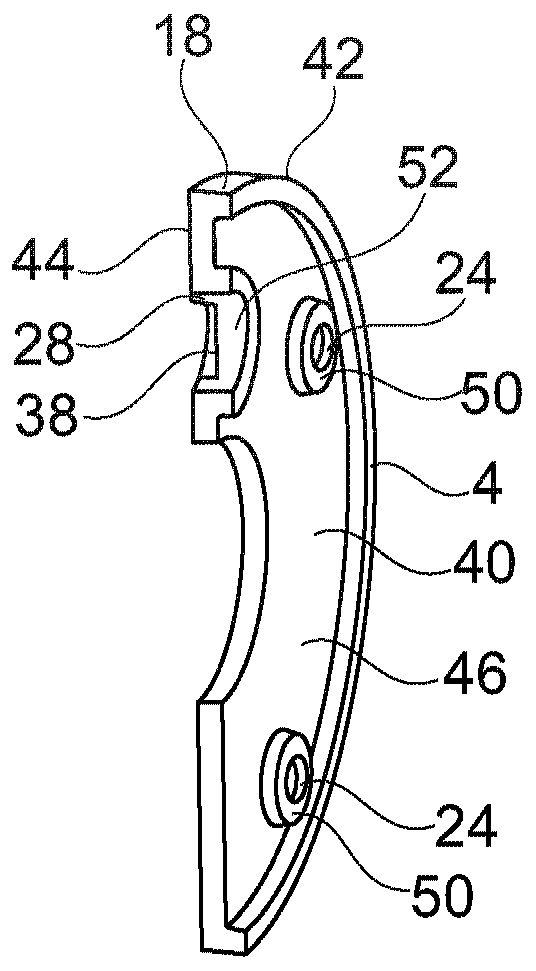

[0016] figure 1 An exemplary cam phaser 10 is shown. Cam phaser 10 is preferably used in conjunction with an engine, such as an internal combustion engine, to vary valve timing in a manner known in the art (eg, via hydraulic pressure). For example, the cam phaser 10 may be a vane unit type cam phaser. The cam phaser 10 preferably includes at least a stator 12 , a rotor 14 , a cover plate 16 , a locking cover 18 , a locking pin assembly 20 and a plurality of fasteners 22 . Depending on the application, cam phaser 10 may include additional components not described here. For example, some configurations may include components such as solenoids, torsion springs, housing pieces, cam pieces, shafts, and the like.

[0017] A rotor 14 is positioned within and rotates within stator 12 (eg, by hydraulic pressure) to vary valve timing in a manner known in the art. For example, a plurality of hydraulic chambers (not shown) may be formed between the rotor 14 and the vanes of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com