A kind of prefabricated door cover structure and its production process

A door cover and connecting plate technology, which is applied in the direction of manufacturing tools and wood processing appliances, etc., can solve problems such as difficult to meet the aesthetic requirements of interior decoration, door cover installation, painting quality cannot be guaranteed, and long construction time. The effect of project quality problems, shortened construction period, not easy to deform or open seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

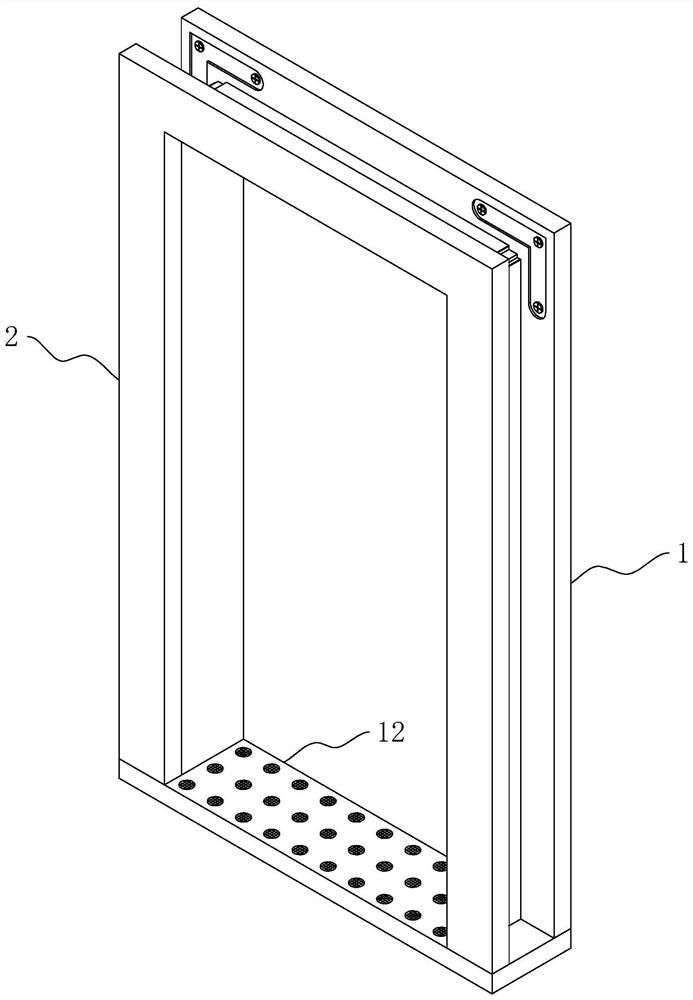

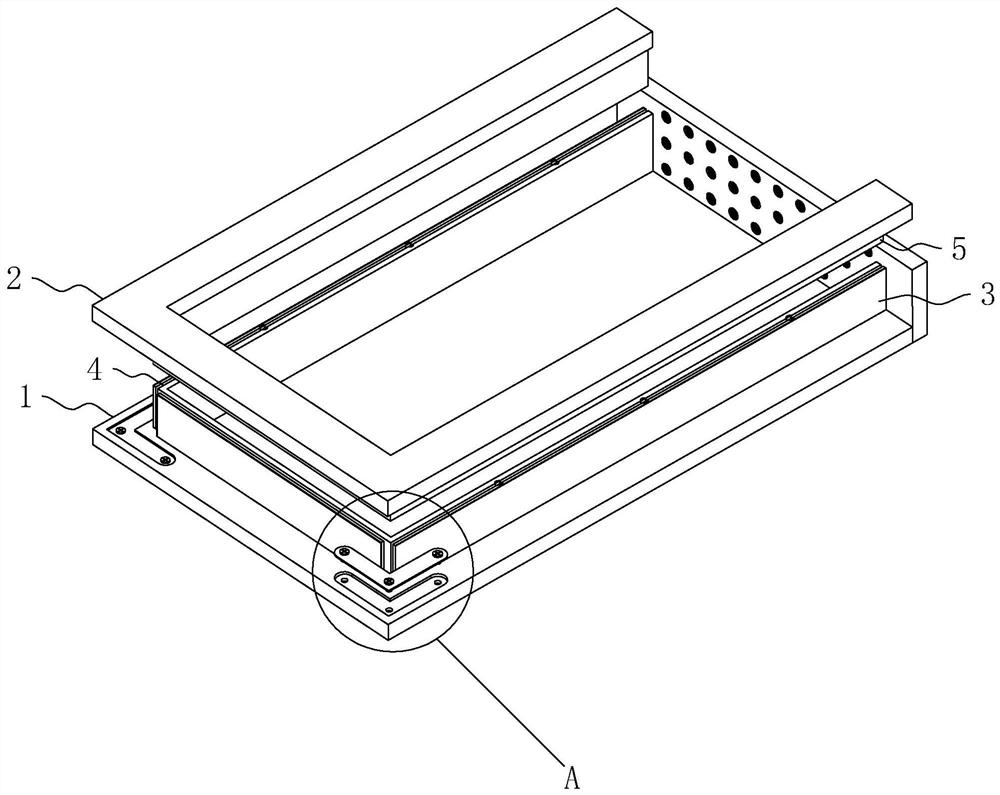

[0043] A prefabricated door pocket structure such as figure 1 , 2 As shown, it includes a door cover base plate 1 and a door cover inserting plate 2. The upper end of the door cover base plate 1 is fixed with a U-shaped connecting plate 3, and the connecting plate 3 is provided with a clamping groove 4, and the door cover inserting plate 2 is fixed with a The clamping plate 5 is U-shaped and tenon-jointed in the clamping groove 4 .

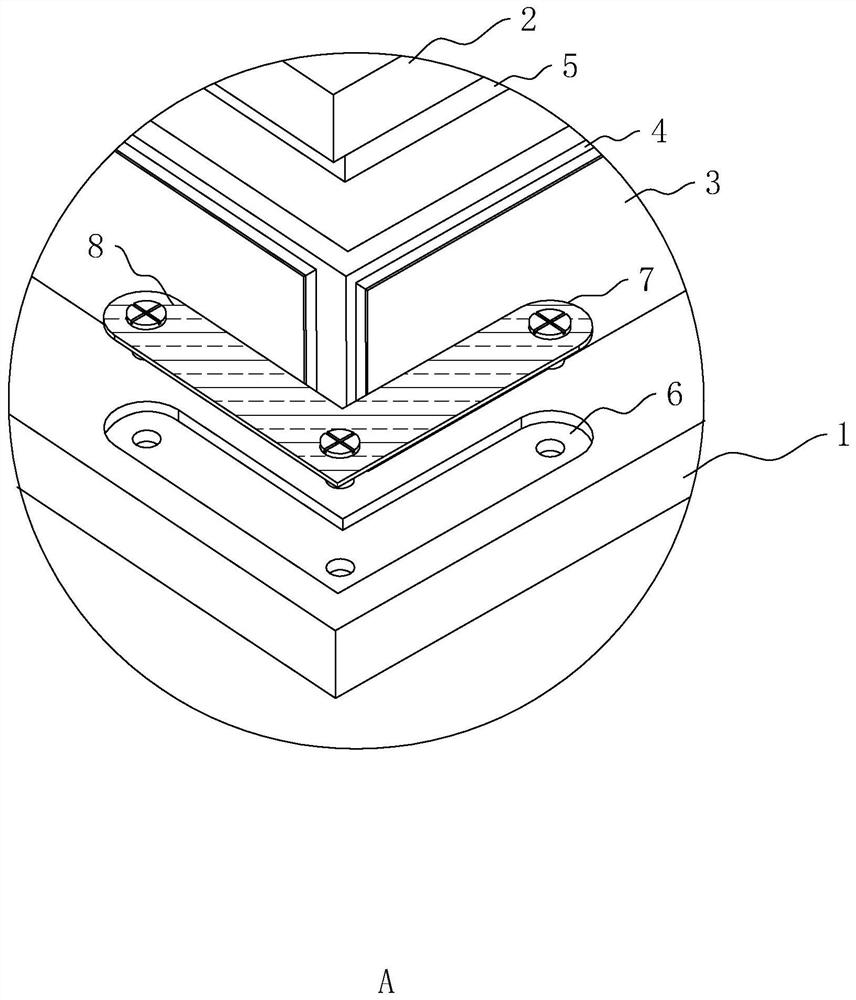

[0044] like image 3 As shown, an L-shaped reinforcement groove 6 is provided at the corner of the door casing base plate 1 and the door casing inserting plate 2, and a metal reinforcement plate 7 is arranged in the reinforcement groove 6, and the metal reinforcement plate 7 is fixed in the reinforcement groove 6 by bolts. Since the door cover base plate 1 and the door cover inserting plate 2 are subjected to high force streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com