ITO film hot pressing forming device and method

A hot press forming, No. 1 technology, applied in the field of ITO film hot press forming equipment, can solve the problems of use limitation, inability to remove impurities and particles, and inability to solve mobile phone heating, etc., and achieve the effect of enhanced plasticity and convenient extrusion molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

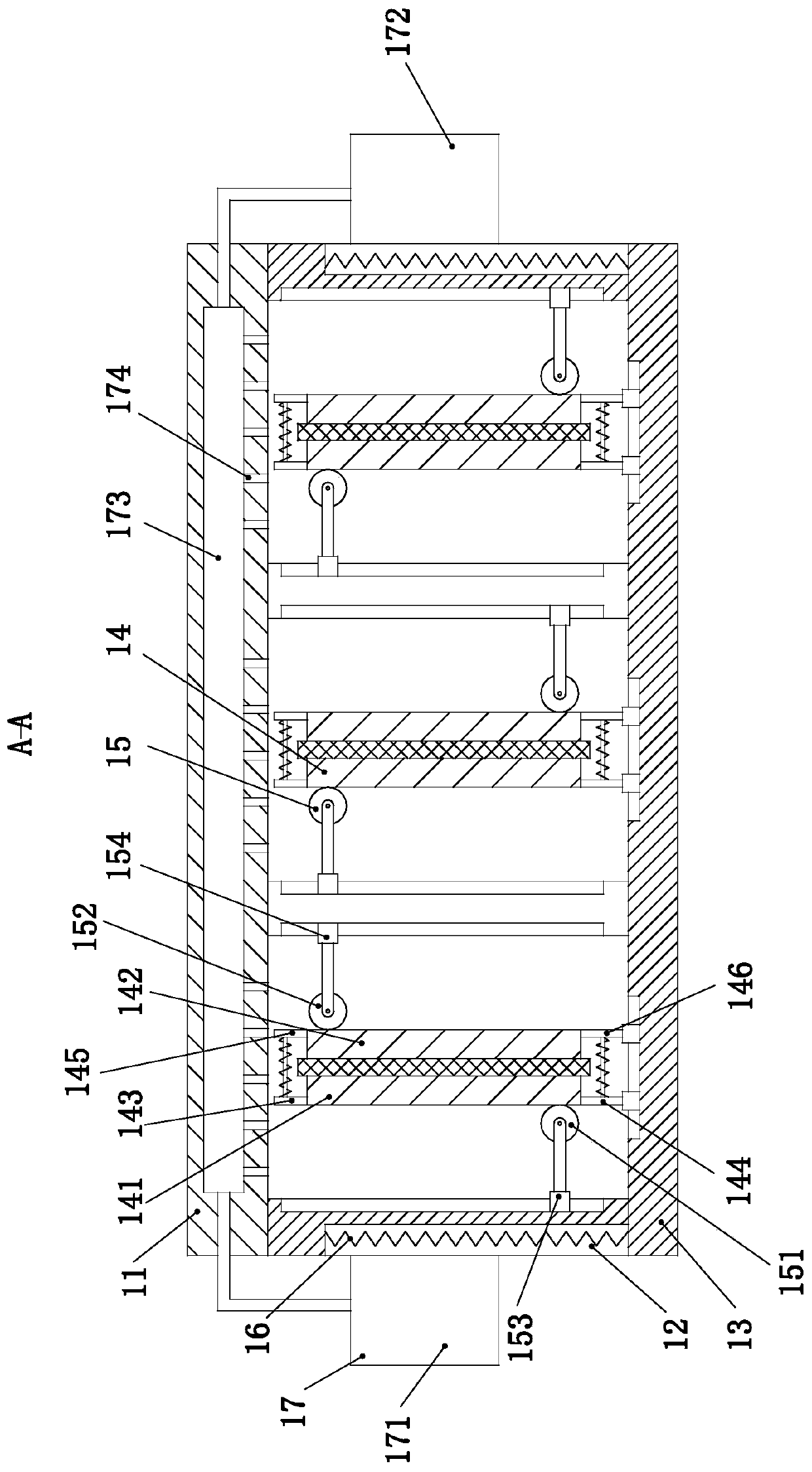

[0031] As an embodiment of the present invention, the clamping unit 14 includes a No. 1 extrusion plate 141, a No. 2 extrusion plate 142, a No. 1 installation block 143, a No. 2 installation block 144, a No. 3 installation block 145 and a No. 4 installation block. Mounting block 146, No. 1 mounting block 143 is fixedly installed on the upper end of No. 1 extrusion plate 141, No. 2 mounting block 144 is fixedly installed on the lower end of No. 1 extrusion plate 141, and No. 3 mounting block 144 is fixedly installed on the upper end of No. 2 extrusion plate 142. Block 145, No. 2 is fixedly installed with No. 4 installation block 146 with respect to the lower end of pressing plate, No. 1 extruding plate 141 and No. 2 extruding plate 142 cooperate to squeeze and fix ITO film;

[0032] The lower end of the No. 2 mounting block 144 is installed in the chute of the base plate 13 by the slide block, and the lower end of the No. 4 mounting block 146 is installed in the chute of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com