Constant force amplitude changing mechanism

A luffing mechanism and constant force technology, applied in the direction of cranes, etc., can solve the problem of the unsteady lifting force of the oil cylinder, and achieve the effect of improving the performance, improving the service life and constant pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

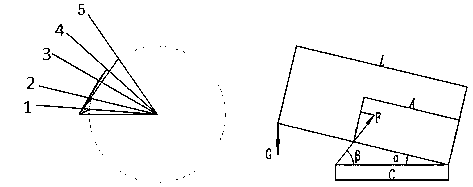

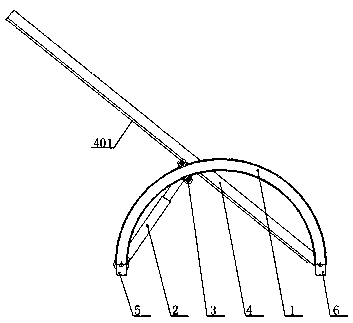

[0034] figure 2 and image 3 As shown, a constant force luffing mechanism includes a slide rail 1, a lifting cylinder 2, a sliding device 3 and a lifting arm 4. The slide rail is semicircular, and the slide rail is symmetrically fixed on the vehicle frame. The tail end of the oil cylinder is fixed on the frame through the hinge seat 5 of the oil cylinder, the working end of the lifting cylinder is rolled and supported on the two slide rails through the sliding device, and the tail end of the lifting arm is fixed on the frame through the hinge seat 6 of the lifting arm Above, the working end of the lifting arm is slidingly connected with the sliding device; during the lifting process of the lifting arm, the included angle between the lifting arm and the lifting cylinder is always a right angle;

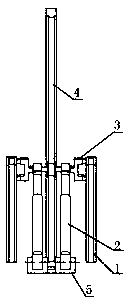

[0035] like Figure 4 As shown, the structure of the sliding device 3 is as follows: comprising a roller bracket 301, the roller bracket is hinged with the working end of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com