Cross flow type fan wing device

A cross-flow fan and cross-flow technology, used in transportation and packaging, aircraft, motor vehicles, etc., can solve the problems of reducing aerodynamic efficiency, fan wing lift fluctuation, device vibration, etc., to reduce fluctuation and vibration, improve assembly efficiency, The effect of improving aerodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

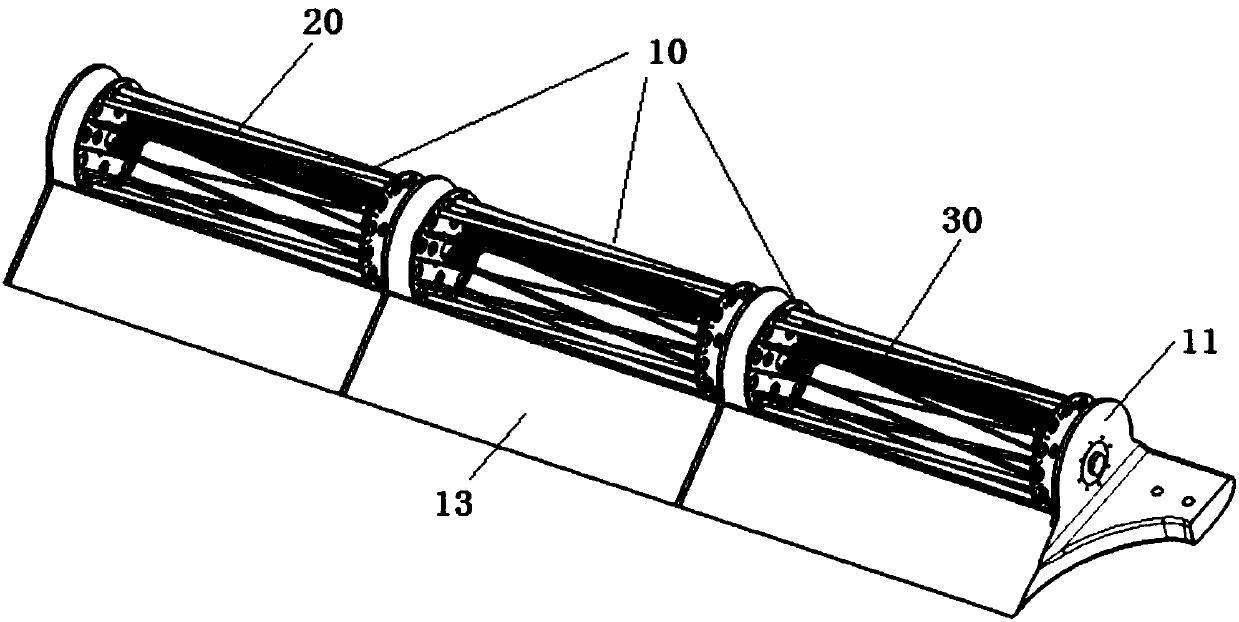

[0052] Such as figure 1 As shown, a cross-flow fan blade device includes several fan blade segments 10 connected in series and a cross-flow fan 20 that is mathematically equivalent to the fan blade segments, and two adjacent fan blade segments are fixedly connected.

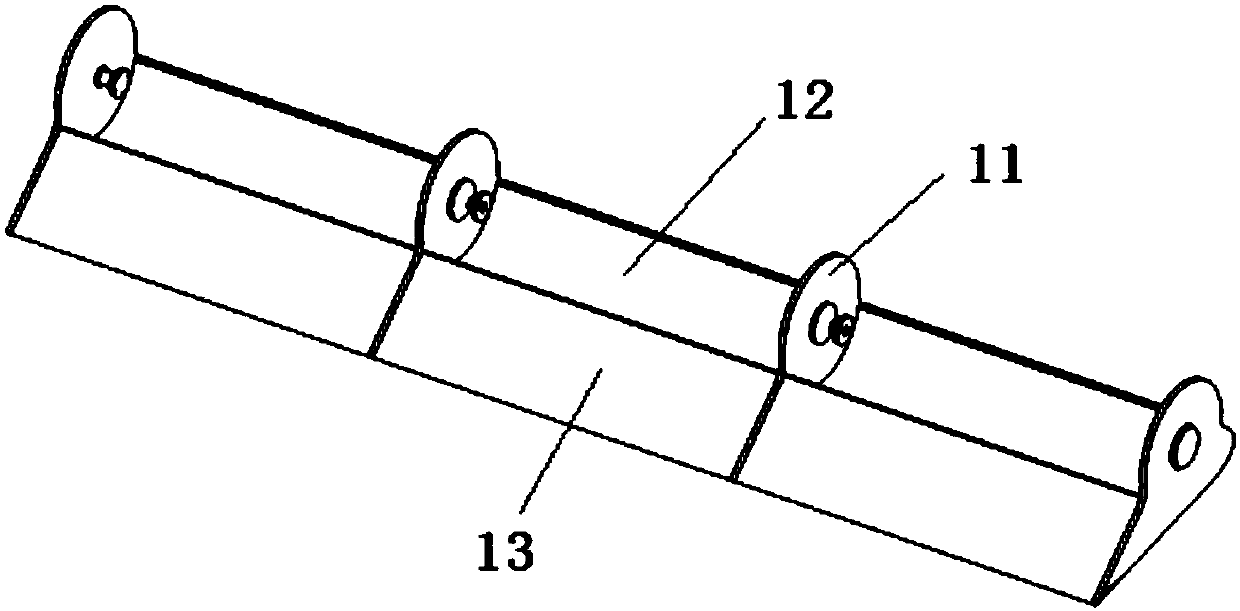

[0053] Such as image 3 As shown, each fan wing segment includes a support plate 11, an aerodynamic upper surface and a lower surface, the front of each fan wing segment forms a leading edge, and the rear of each fan wing segment Form the trailing edge.

[0054] The support plate 11 is preferably arranged on one end surface or both end surfaces of each fan wing segment, when the support plate is arranged on one end surface of each fan wing segment, such as image 3 As shown, two adjacent fan wing segments share a support plate.

[0055] When the support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com