Method for preparing anode of aluminum-air battery by recovering aluminum

An aluminum-air battery and a technology for recycling aluminum, which is applied to battery electrodes, primary battery electrodes, fuel cell half-cells, and primary battery half-cells, etc., which can solve the difficulties in recycling waste aluminum materials and serious self-corrosion hydrogen evolution reactions , reduce the utilization rate of aluminum negative electrode and the output power of aluminum-air battery, and achieve the effect of improving the utilization rate of anode and battery power, reducing the rate of hydrogen evolution self-corrosion, and refining the alloy grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1

[0035] This embodiment specifically includes the following steps:

[0036] 1. Put the squashed and cleaned cans, aluminum scraps, and machined aluminum scraps directly into the cold processing crusher feed bin, and crush them into powder, with an average particle size of 1-3mm, and the particle shape is spherical, hemispherical and prismatic; For scrap aluminum wire and waste extruded profiles, first cut them into line segments, according to the requirements of the finished powder, cut off the length of 4 to 6 mm, and the uniform specifications of the line segment wool are processed by the cold processing crusher, and the average powder particle size is 1-3 mm , The shape of the particles is spherical, hemispherical and prismatic.

[0037] 2. Mix the waste aluminum powder, the foaming agent and the additional elements Mg and Sn in the following proportions, and then perform pressure molding: the foaming agent content is 1.0%, the specific content of Mg is 1%, the ...

Example Embodiment

[0039] Example 2

[0040] This embodiment specifically includes the following steps:

[0041] 1. Melt waste aluminum materials such as cans, aluminum wires, waste extruded profiles, aluminum plate scraps, machined aluminum scraps, and waste aluminum alloy cylinders into molten aluminum at a melting temperature of 720℃;

[0042] 2. By adding a thickener and stirring to thicken the melt, the selected thickener is industrial metal Ca with a mass fraction of 2.5%;

[0043] 3. Add foaming agent, add TiH2 with mass fraction of 1.2% and stir for 8min, temperature is 680℃;

[0044] 4. Thermal insulation foaming, take out the stirrer, and place the melt at 600°C for 12 minutes to complete the foaming process;

[0045] 5. Cool, take out the crucible from the furnace and cool down naturally at room temperature.

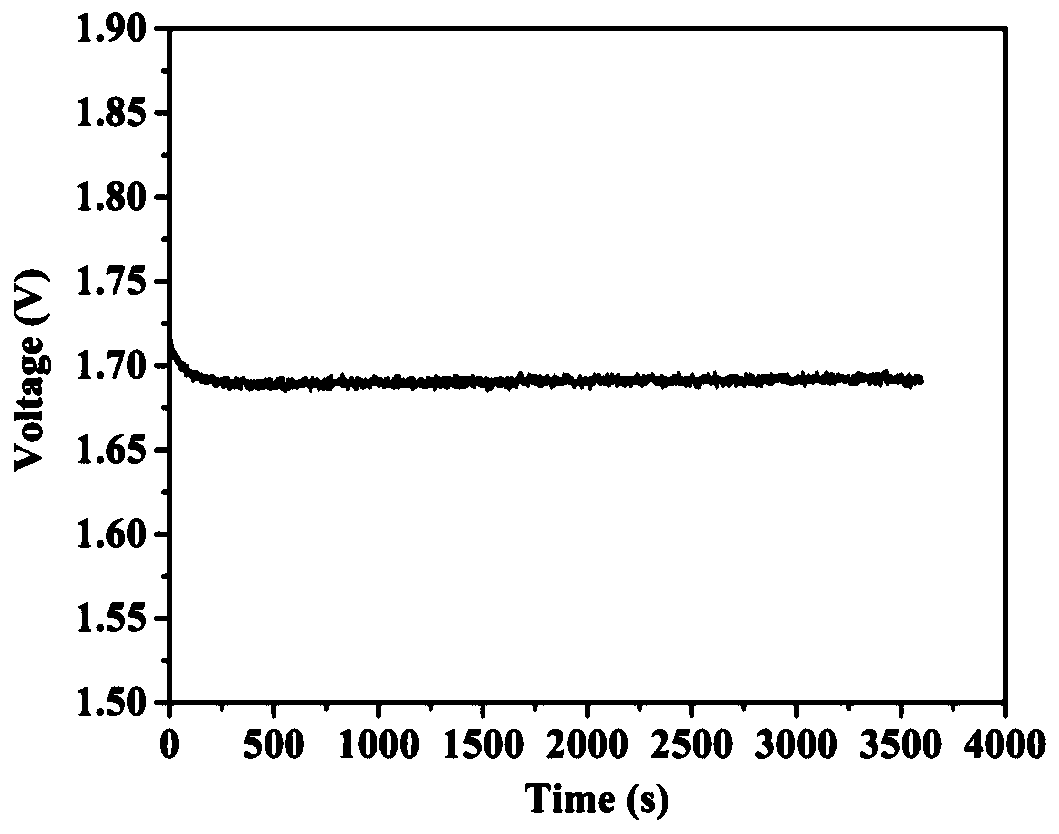

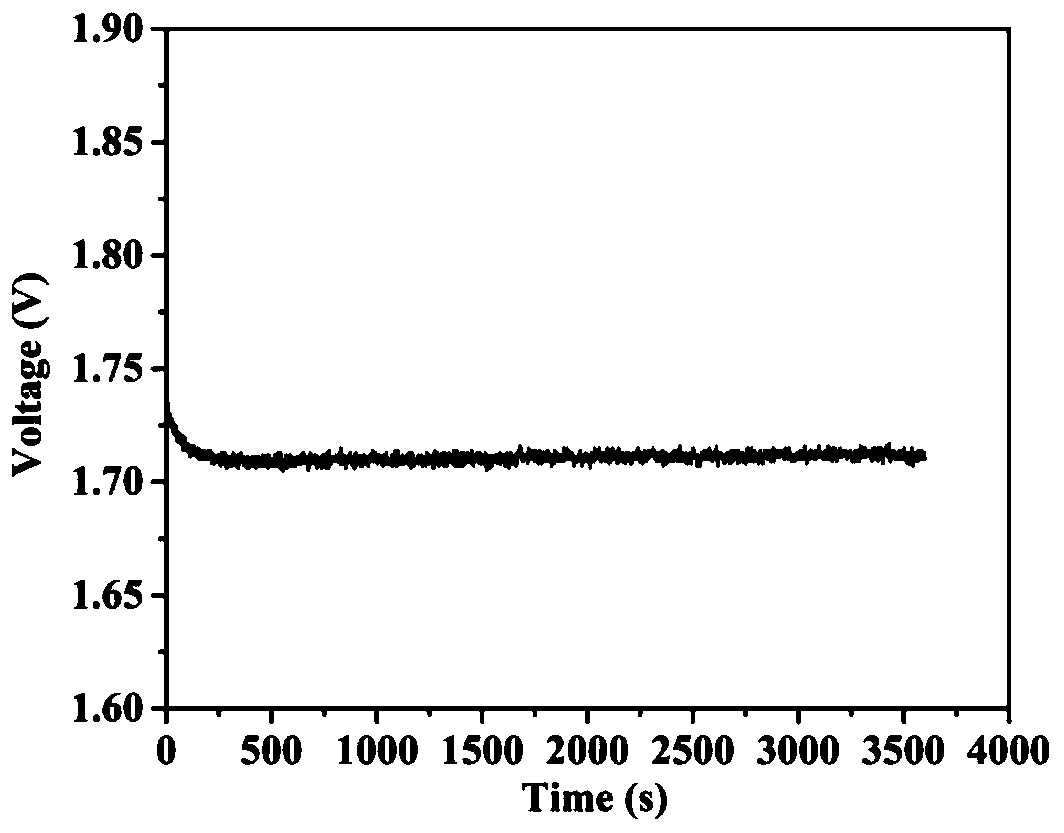

[0046] The foamed aluminum alloy material prepared by the above method is further subjected to extrusion and cutting to obtain the aluminum alloy anode material; the prepared anode material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com