Municipal road construction surrounding baffle mounting structure and construction method thereof

A technology for construction fences and municipal roads, applied to fences, building types, buildings, etc., can solve the problems of slow construction and dismantling, low construction efficiency, and a large amount of manpower, and achieve reduced manual operations, high safety, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

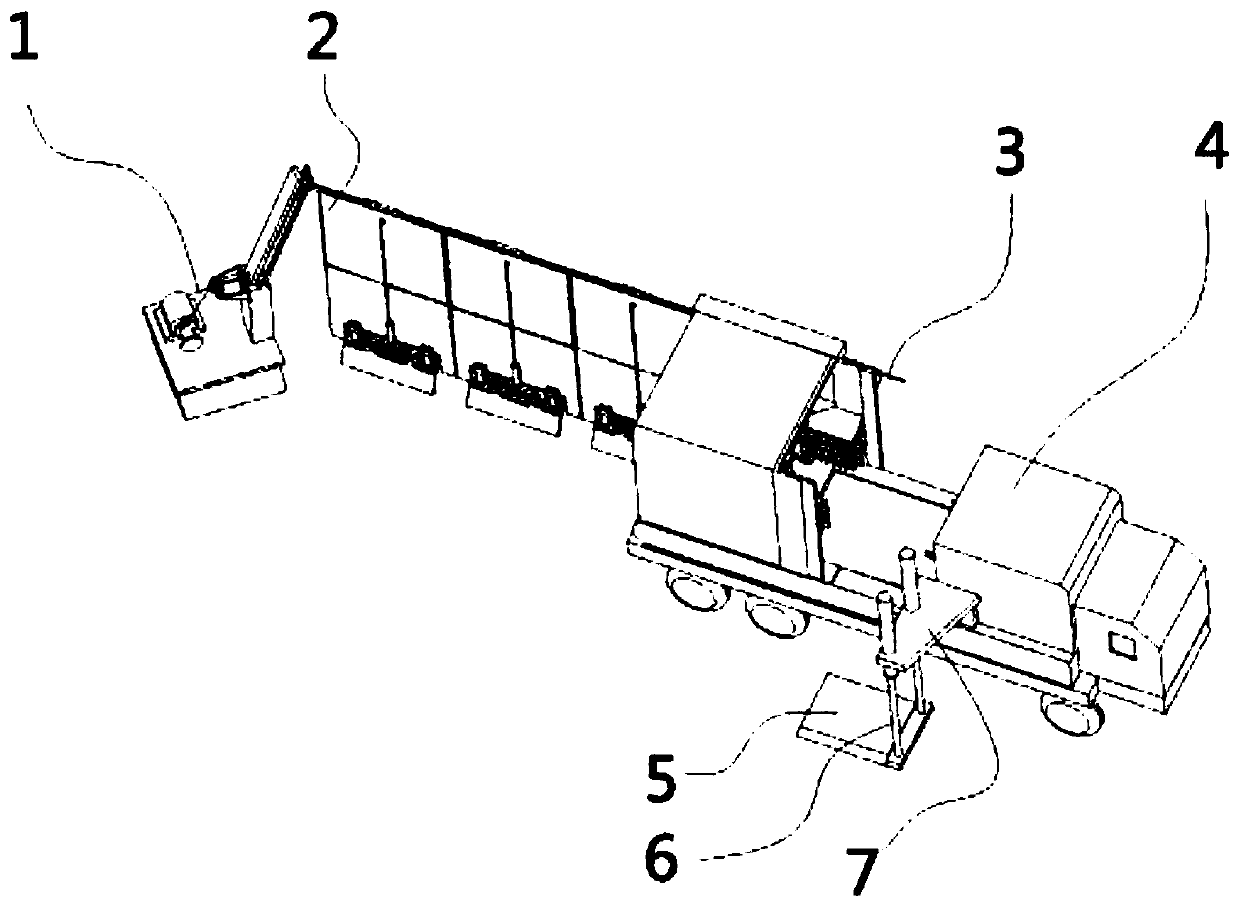

[0032] The installation structure of the municipal road construction enclosure baffle includes a pull wire device 1, an engineering vehicle 4, and a barrier 2. The engineering vehicle 4 is connected with the pull wire device 1 through a traction device; There is the hook that catches wire rope 3.

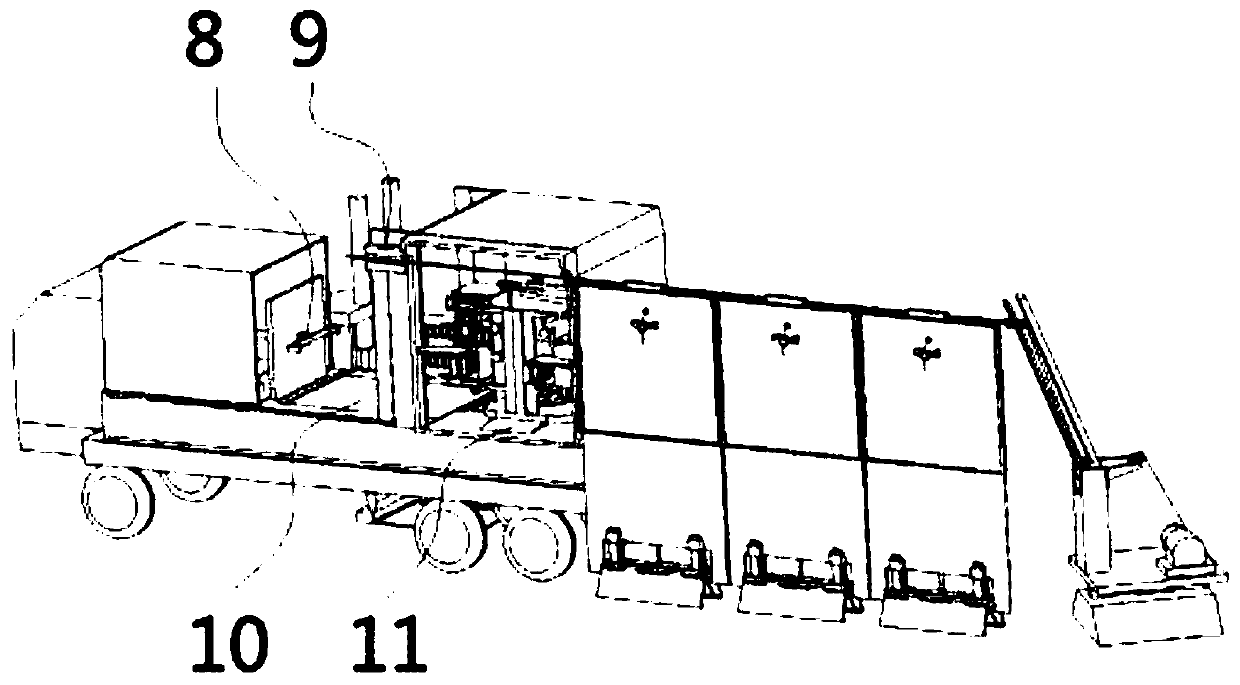

[0033] The front section of engineering vehicle 4 is equipped with push arm 8, and described push arm 8 is connected with the hydraulic push rod 22 that is fixed on engineering vehicle 4, and described hydraulic push rod 22 and push arm 8 contact places are installed with baffle plate 23, and baffle plate 23 to prevent barrier 2 from falling. The middle section of the engineering vehicle 4 is equipped with a conveyor belt 10. During the construction process, the conveyor belt 10 can move or not. Meanwhile, the transmission speed can also be adjusted. In this embodiment, the conveyor belt 10 moves slowly.

[0034] The rear end of engineering vehicle 4 is equipped with frame body 24,...

Embodiment 2

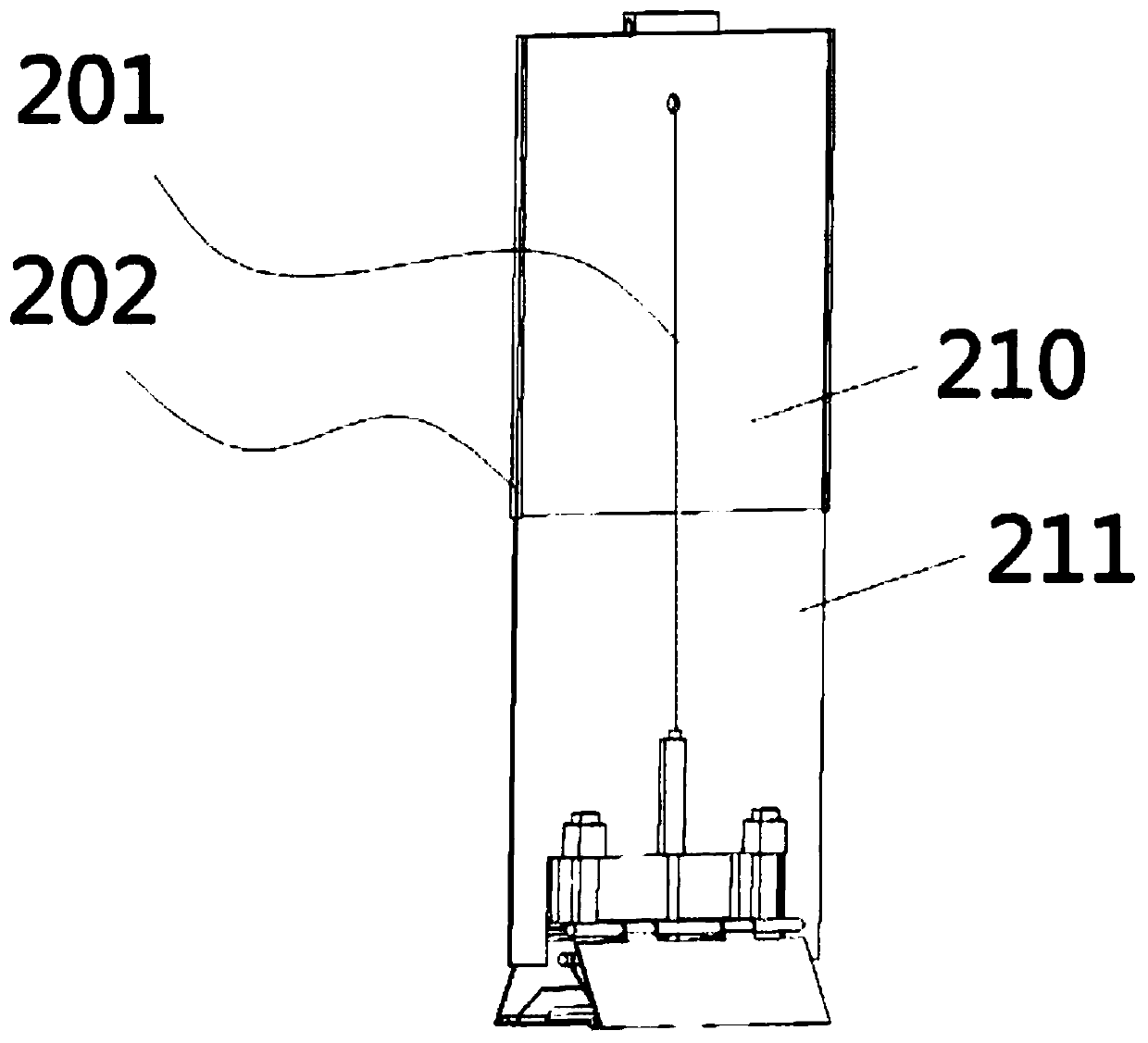

[0046] Municipal road construction fence installation structure, including pull wire device 1, engineering vehicle 4, barrier 2, said engineering vehicle 4 is connected with pull wire device 1 through traction device; The quantity of each transportation is limited. In order to solve this problem, save the volume of the barrier and increase the transportation volume, in the present embodiment, the barrier barrier 2 includes an upper barrier 210 and a lower barrier 211, and the two sides of the upper barrier 210 are provided with sideslips Groove 202 slides into the inside of upper barrier 210 for lower barrier 211; The top of described upper barrier 210 ' is equipped with hanging groove 203, and cable locker 204 is installed on the upper barrier 210, and it is locked on it and has to pass through from the back. The steel cable 201 is connected with the lower barrier 211 at the same time, and a folded barrier can also be used at the same time.

[0047] The front section of engin...

Embodiment 3

[0060] Municipal road construction fence installation structure, including pull wire device 1, engineering vehicle 4, barrier 2, said engineering vehicle 4 is connected with pull wire device 1 through traction device; The quantity of each transportation is limited. In order to solve this problem, save the volume of the barrier and increase the transportation volume, in the present embodiment, the barrier barrier 2 includes an upper barrier 210 and a lower barrier 211, and the two sides of the upper barrier 210 are provided with sideslips Groove 202 slides into the inside of upper barrier 210 for lower barrier 211; The top of described upper barrier 210 ' is equipped with hanging groove 203, and cable locker 204 is installed on the upper barrier 210, and it is locked on it and has to pass through from the back. The steel cable 201 is connected with the lower barrier 211 at the same time, and a folded barrier can also be used at the same time. In addition, in order to solve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com