A miniaturized high-precision optical gravimeter with optical cooling

A high-precision, gravimeter technology, applied in the field of precision measurement, can solve the problems of complex reset, large volume, and many error factors, and achieve the effect of no initial speed error, no mechanical support change, and reduced position uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

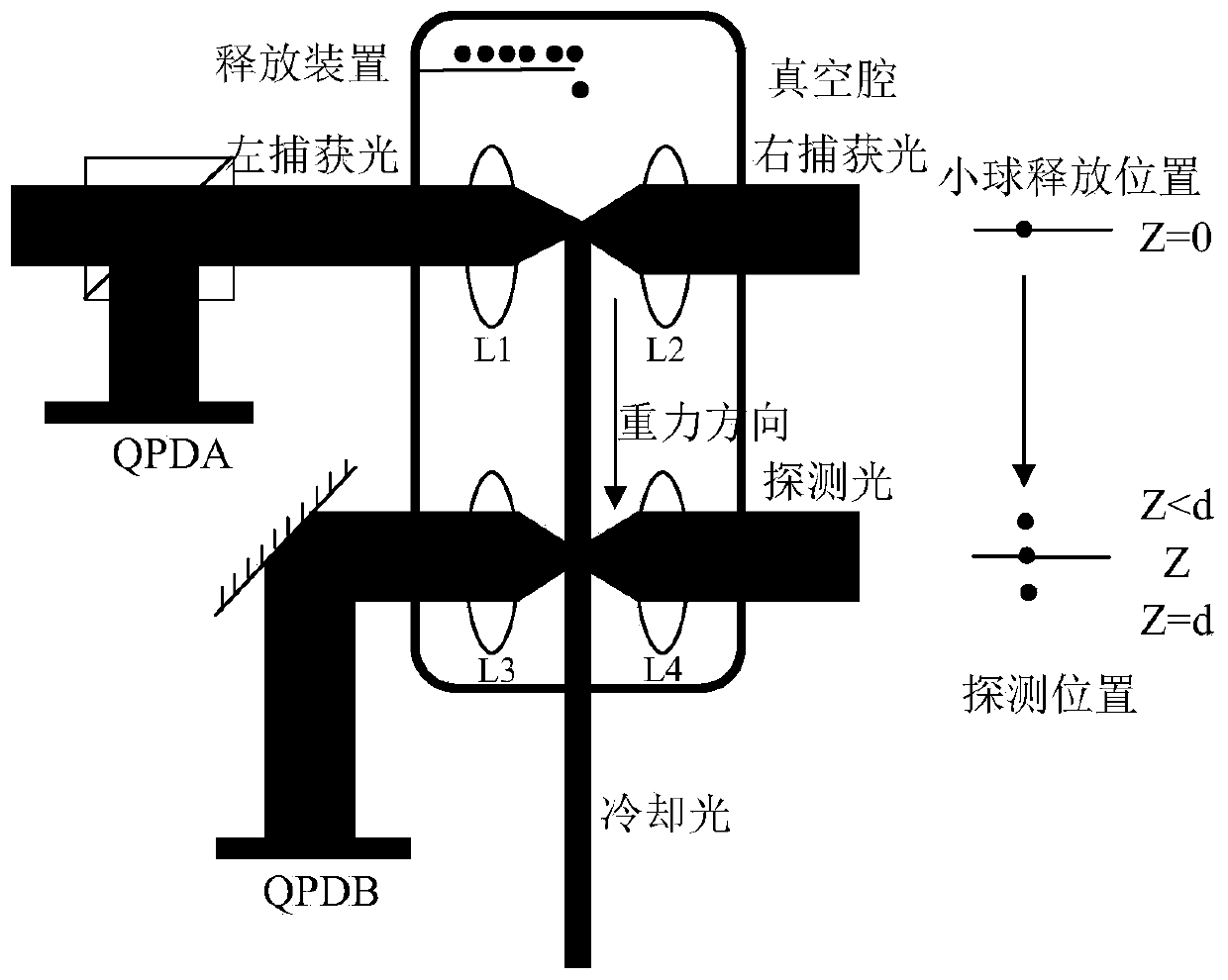

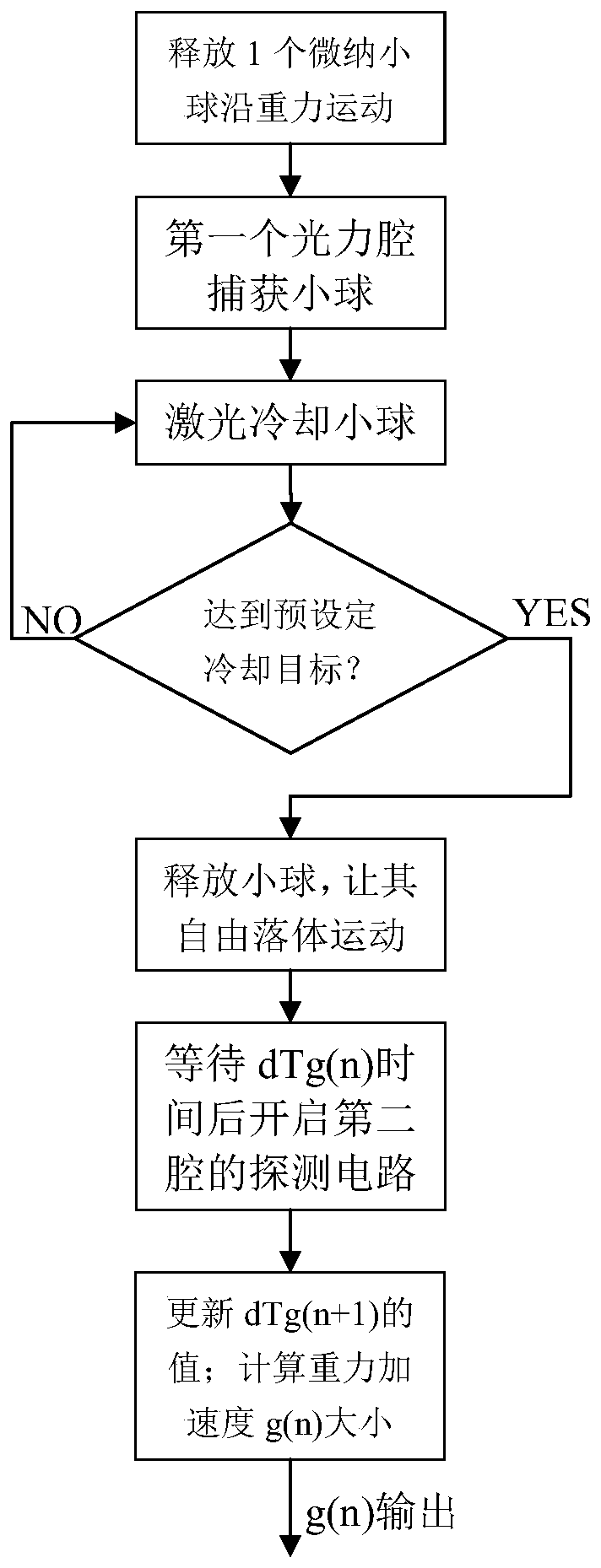

[0062] Such as figure 2 As shown, the gravimeter includes a vacuum chamber and a release device located in the vacuum chamber, a laser cooling chamber, an optical detection chamber and micro-nano balls; the release device is on the top of the vacuum chamber, and the initial micro-nano balls are loaded in the release device , the laser cooling cavity and the optical detection cavity are respectively located above and below the middle of the vacuum cavity, and the release position of the release device, the laser cooling cavity and the optical detection cavity are arranged in sequence from top to bottom along the vertical direction of gravity;

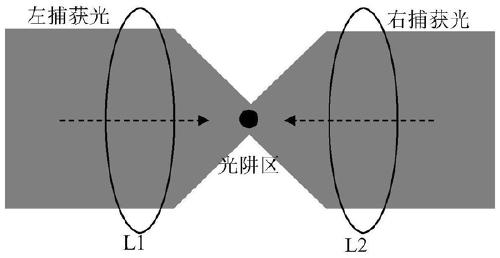

[0063] Such as figure 2 As shown, the laser cooling cavity is equipped with a laser capture device of micro-nano balls. The laser capture device includes two lenses L1 and L2 arranged horizontally opposite to the opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com