Method and system for automatically detecting backlight of panel

A technology of automatic detection and detection algorithm, applied in the direction of optics, nonlinear optics, instruments, etc., can solve the problems of low detection efficiency and low accuracy, and achieve the effect of improving accuracy, ensuring accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

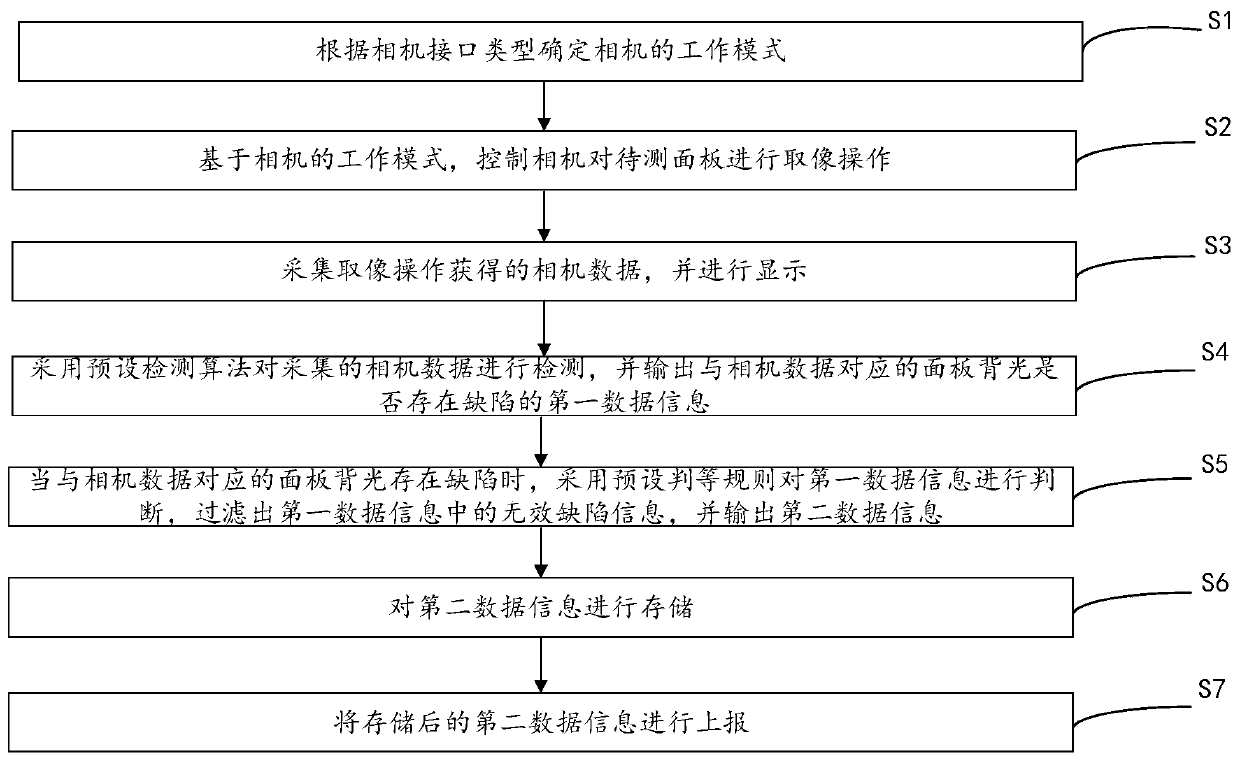

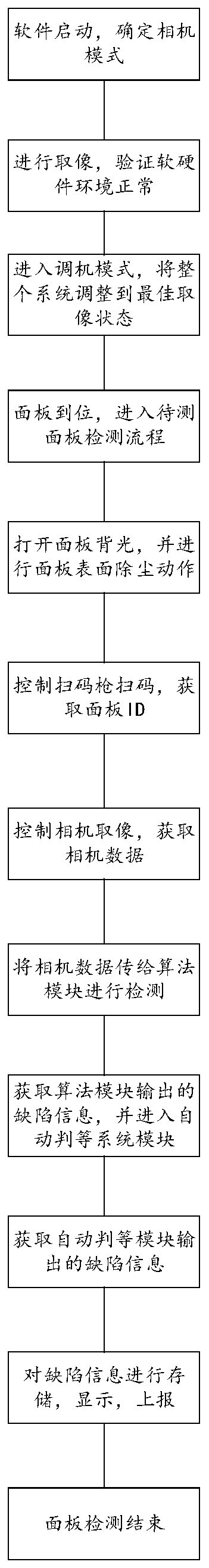

[0058] This embodiment provides a method for automatically detecting panel backlight, please refer to figure 1 , the method includes:

[0059] First execute step S1: determine the working mode of the camera according to the type of the camera interface.

[0060]Specifically, the camera interface is divided into a USB interface, a network interface and an AOI hardware platform interface. In this embodiment, these three interfaces are supported. When the optical scheme is determined, the appropriate interface control method can be selected according to the camera type selected in the optical scheme, so that the cost can be minimized.

[0061] Then step S2 is executed: based on the working mode of the camera, the camera is controlled to perform an image capturing operation on the panel to be tested.

[0062] In one embodiment, controlling the camera to perform an image capturing operation of the panel to be tested includes:

[0063] By adjusting the angle and focal length of t...

Embodiment 2

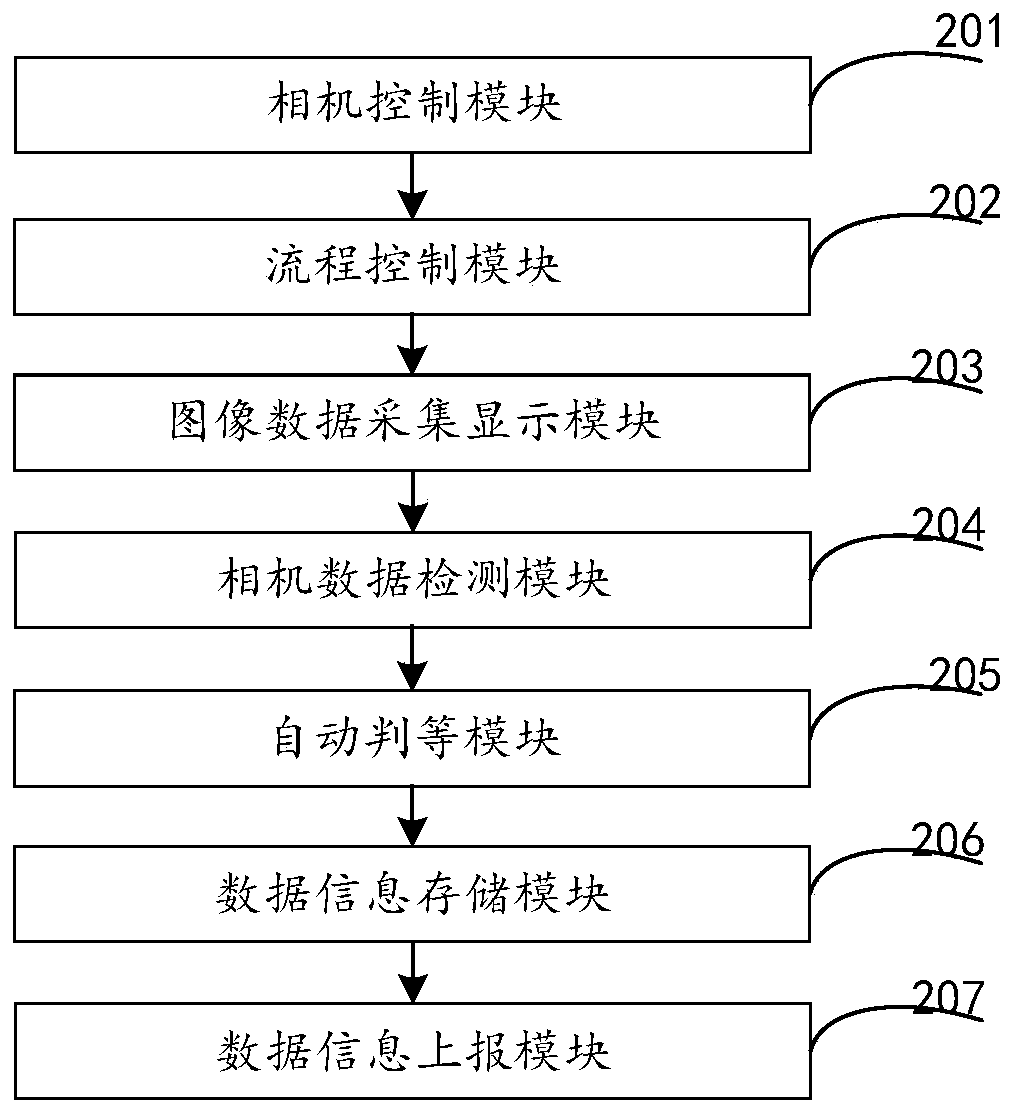

[0101] This embodiment provides a system for automatically detecting panel backlight, please refer to figure 2 , the system consists of:

[0102] A camera control module 201, configured to determine the working mode of the camera according to the type of the camera interface;

[0103] A process control module 202, configured to control the camera to perform an imaging operation on the panel to be tested based on the working mode of the camera;

[0104] The image data collection and display module 203 is used to collect and display the camera data obtained by the imaging operation;

[0105] The camera data detection module 204 is configured to detect the collected camera data by using a preset detection algorithm, and output the first data information of whether the panel backlight corresponding to the camera data is defective;

[0106] The automatic judgment module 205 is used for judging the first data information by using preset judgment rules when the panel backlight cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com