Shipborne circulating aquaculture system

A technology of recirculating aquaculture and recirculating water, applied in the field of aquaculture system, can solve the problems of large land occupation and low average aquaculture volume, and achieve the effects of improving economic benefits, reducing aquaculture risks, and diluting operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings.

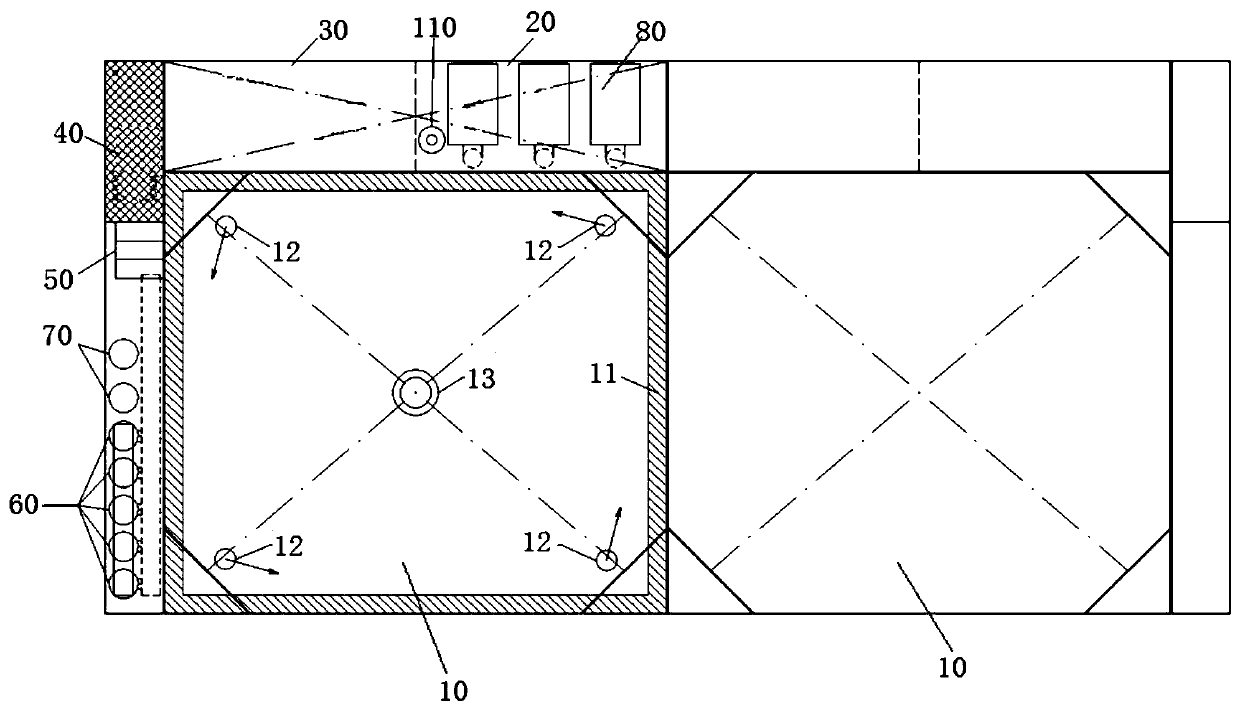

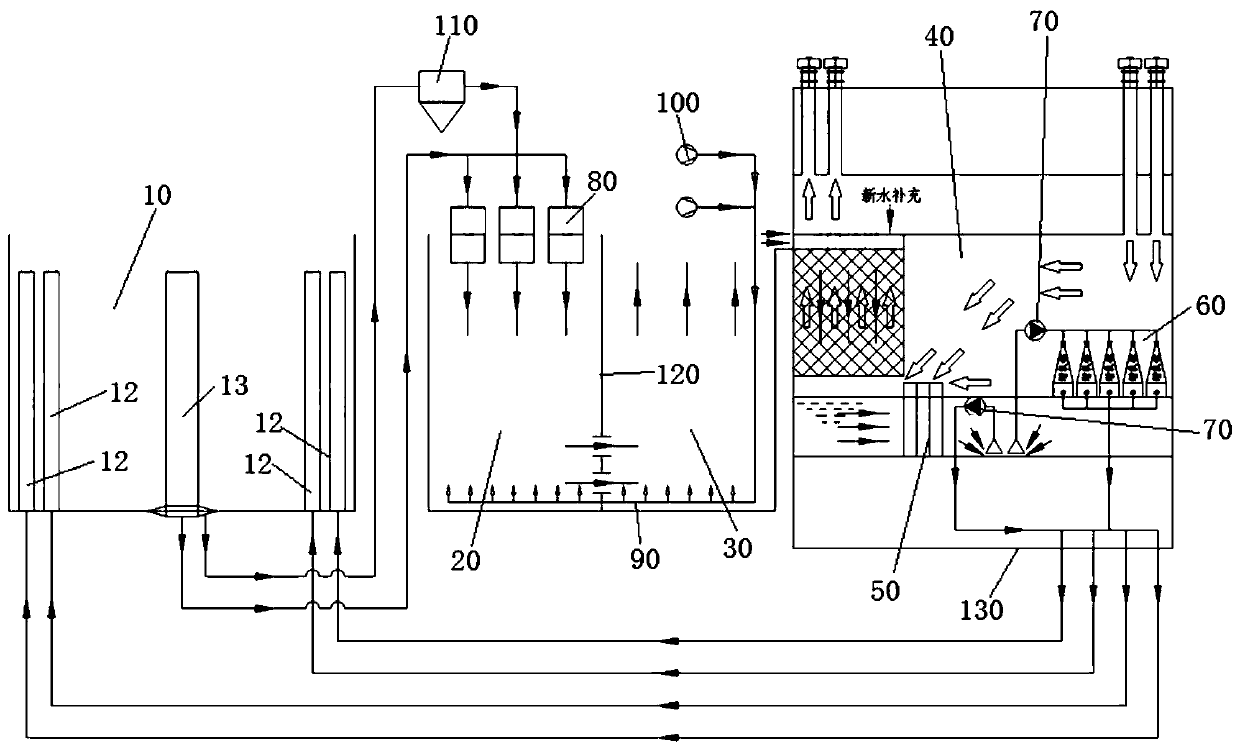

[0041] See figure 1 with figure 2 As shown, the present invention discloses a ship-borne circulating water aquaculture system, including several breeding cabins 10 and several circulating water treatment systems coordinated with the several breeding cabins. The number of breeding cabins 10 and circulating water treatment systems are set according to actual needs. No need to repeat here, one breeding cabin is equipped with a circulating water treatment system.

[0042] The horizontal section of the breeding cabin 10 is designed as an octagon (the four corners of the square are chamfered to form an octagon), and the chamfered side length of the square accounts for about 20% of the total side length; the breeding cabin is made of welded steel plates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com