Flexible laser cleaning system applicable to bend pipeline

A technology for laser cleaning and bending pipes, which is applied in the field of flexible laser cleaning systems, can solve problems such as large noise, limitations, and high precision damage, and achieve the effects of improving laser cleaning efficiency, improving movement coordination, and improving bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

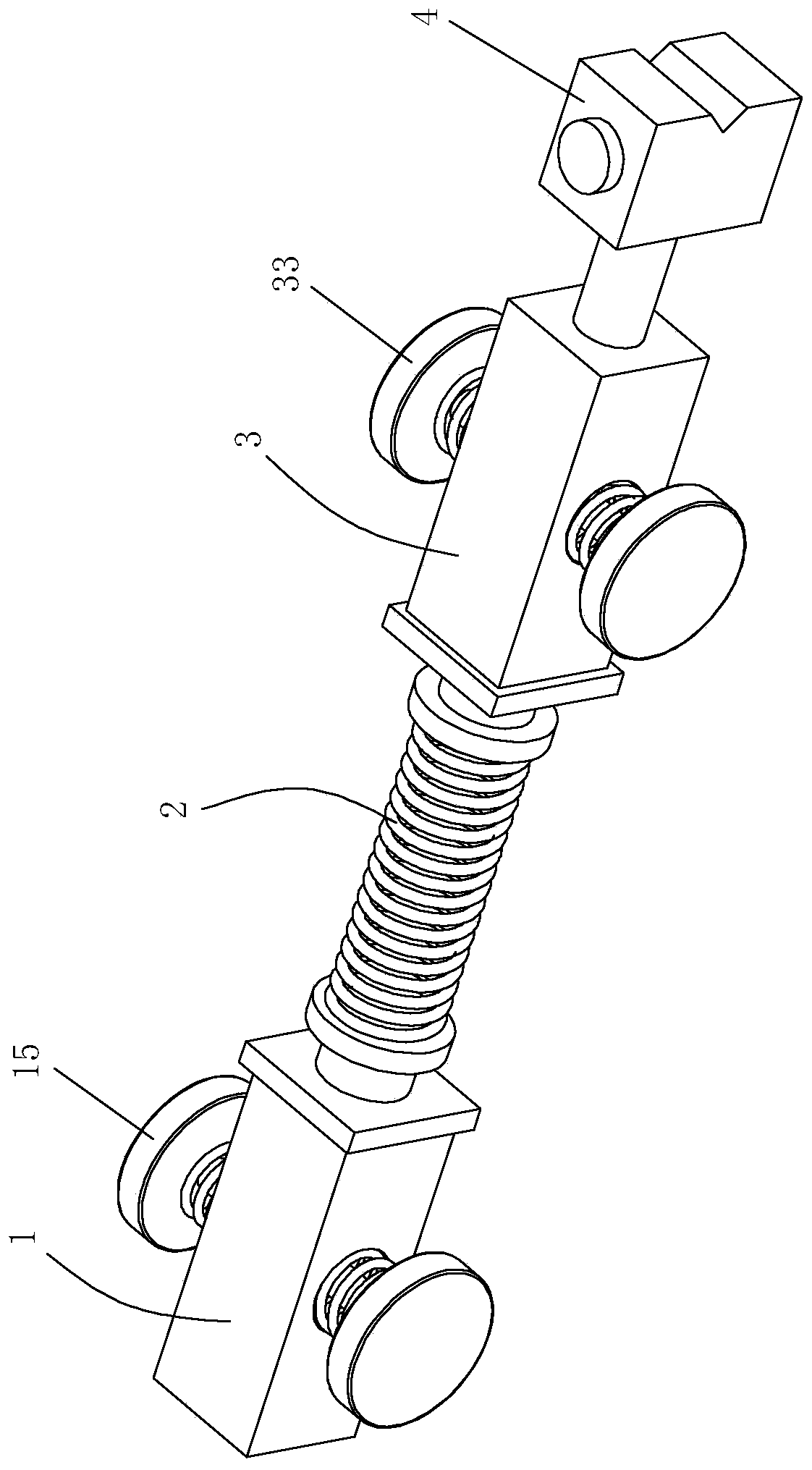

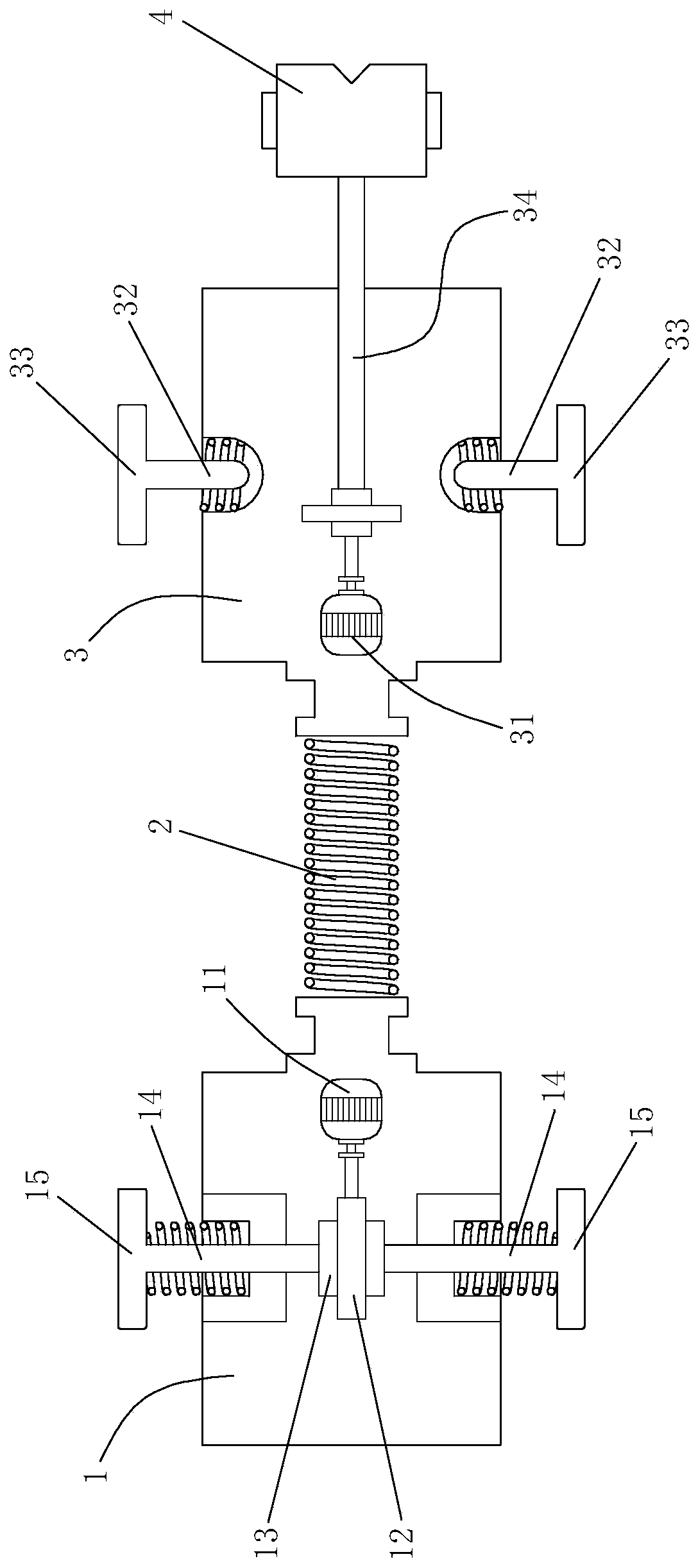

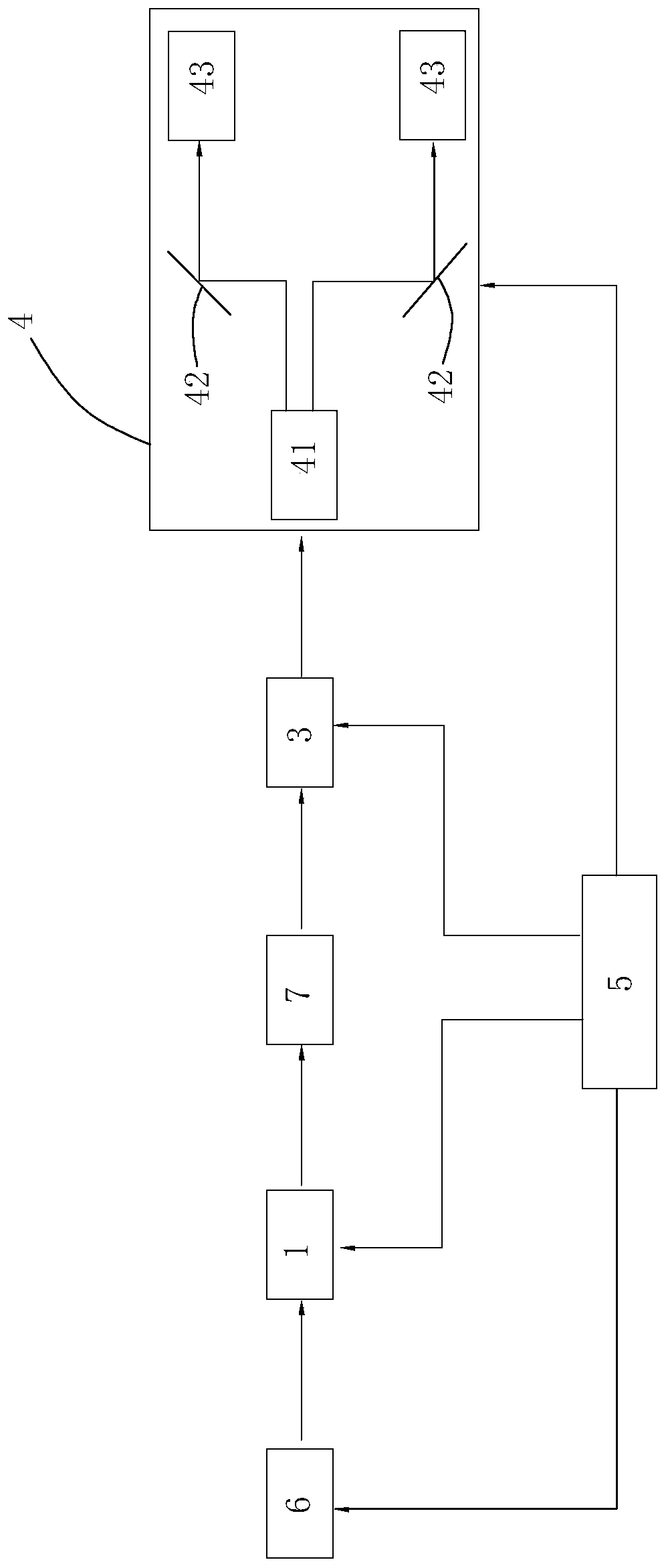

[0027] like Figure 1 to Figure 3 Shown is a flexible laser cleaning system suitable for curved pipelines. The pipeline is a metal pipeline. The laser cleaning system includes a laser 6, a crawling device and a control system 5. The laser 6 is set outside the pipeline when in use, and the laser 6 is an optical fiber. As for the laser, the output laser wavelength is 1064nm, and the laser 6 can also be any one of fiber laser, pulse laser, carbon dioxide laser and semiconductor laser.

[0028] The crawling device comprises a front housing 1, a rear housing 3 and a laser cleaning head 4. The front housing 1 has a driving motor 11, a front driving wheel 15 and a laser access port, and the driving motor 11 is built in the front housing 1, and is connected to the front housing 1. The drive wheels 15 are connected to drive the front drive wheels 15 to rotate. The rear casing 3 has a cleaning motor 31 and a rear driven wheel 33. The cleaning motor 31 is built in the rear casing 3, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com