Commercial vehicle frame assembly

A commercial vehicle and vehicle frame technology, applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problems of increasing radiator area, limited width, radiator assembly width, etc., and achieve the goal of increasing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but this embodiment should not be construed as limiting the present invention.

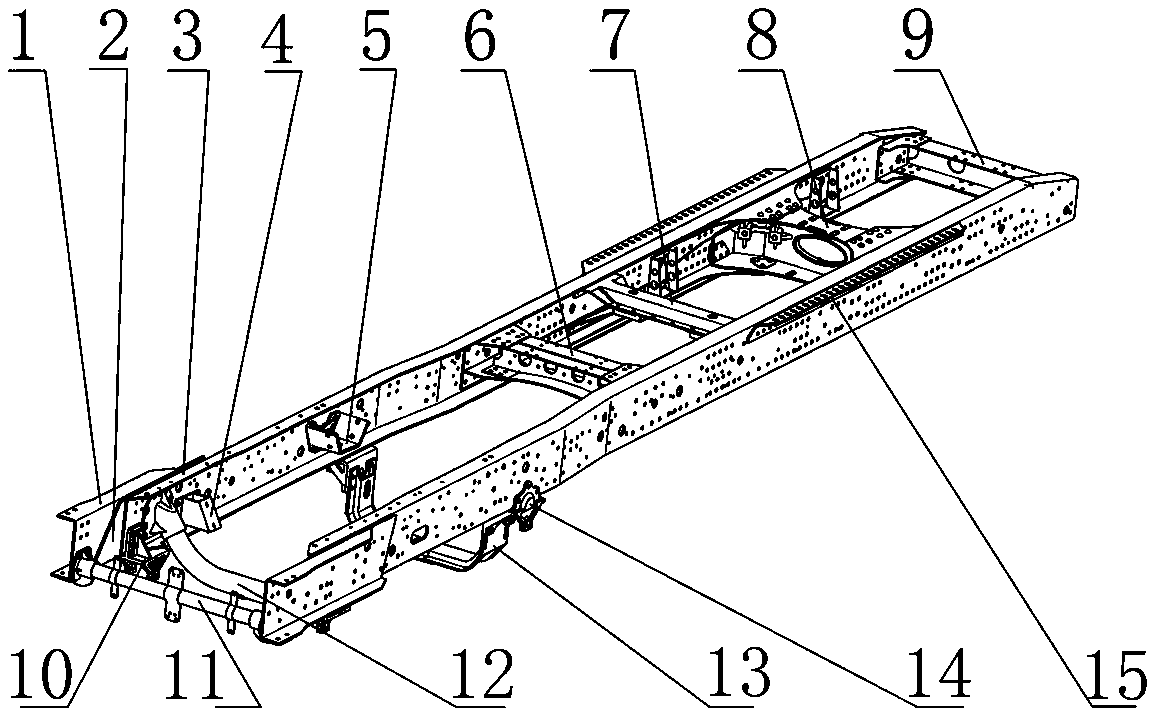

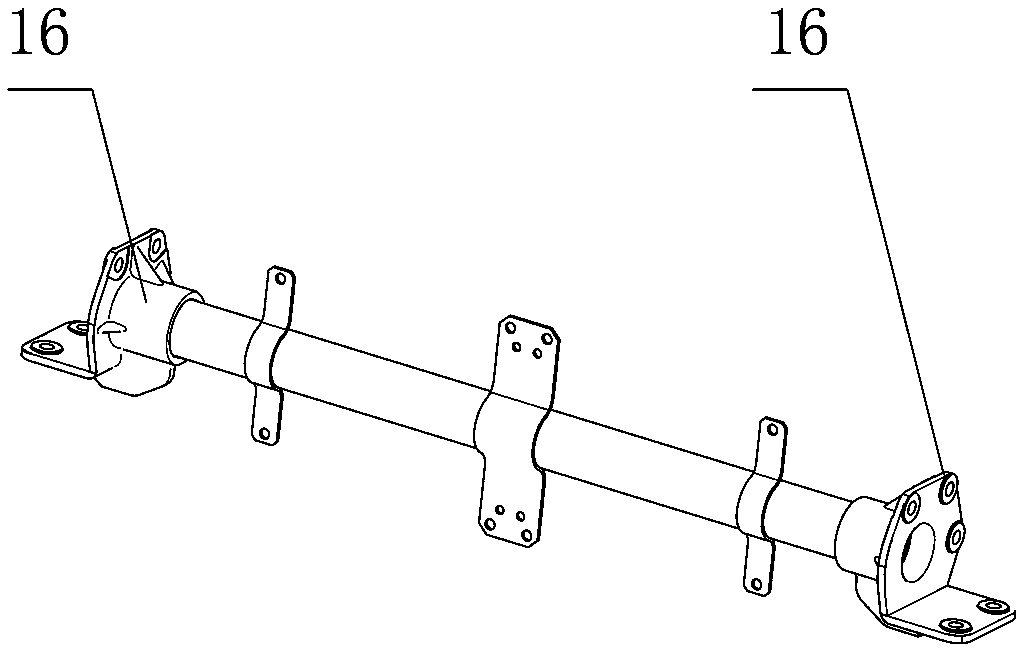

[0014] The present invention as Figure 1 to Figure 2 Shown:

[0015] A commercial vehicle frame assembly, comprising left and right longitudinal beams 3, the cross-section of the left and right longitudinal beams 3 is U-shaped and the openings are arranged inwardly, and the front-end ventral sides of the left and right longitudinal beams 3 are fixed with a The left and right side beams 1 are extended from the front ends of the left and right longitudinal beams 3, and the two ends of the first beam assembly 11 are respectively installed under the front ends of the left and right side beams 1;

[0016] The cross-section of the left and right valgus 1 is a U-shaped structure and the opening is set outward, and is fixedly connected with the outside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com