Steel wire rope monitoring device applied to active safe elevator

An active safety and monitoring device technology, applied in transportation, packaging, elevators, etc., can solve problems such as the inability to guarantee the absolute safety of elevators, hidden dangers of elevator safety, and incomplete investigation, so as to prevent the failure of real-time monitoring functions, reduce workload, and reduce The effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

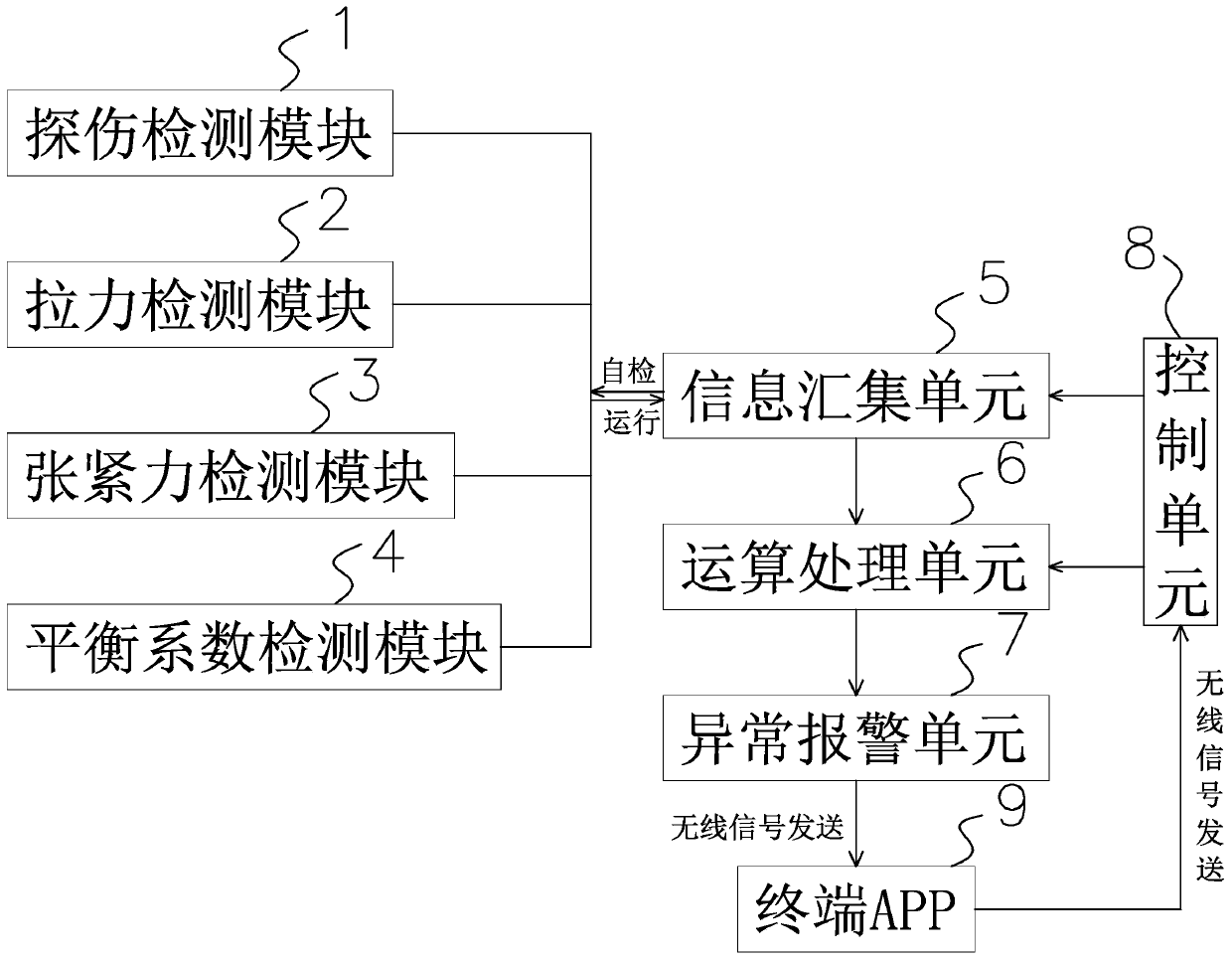

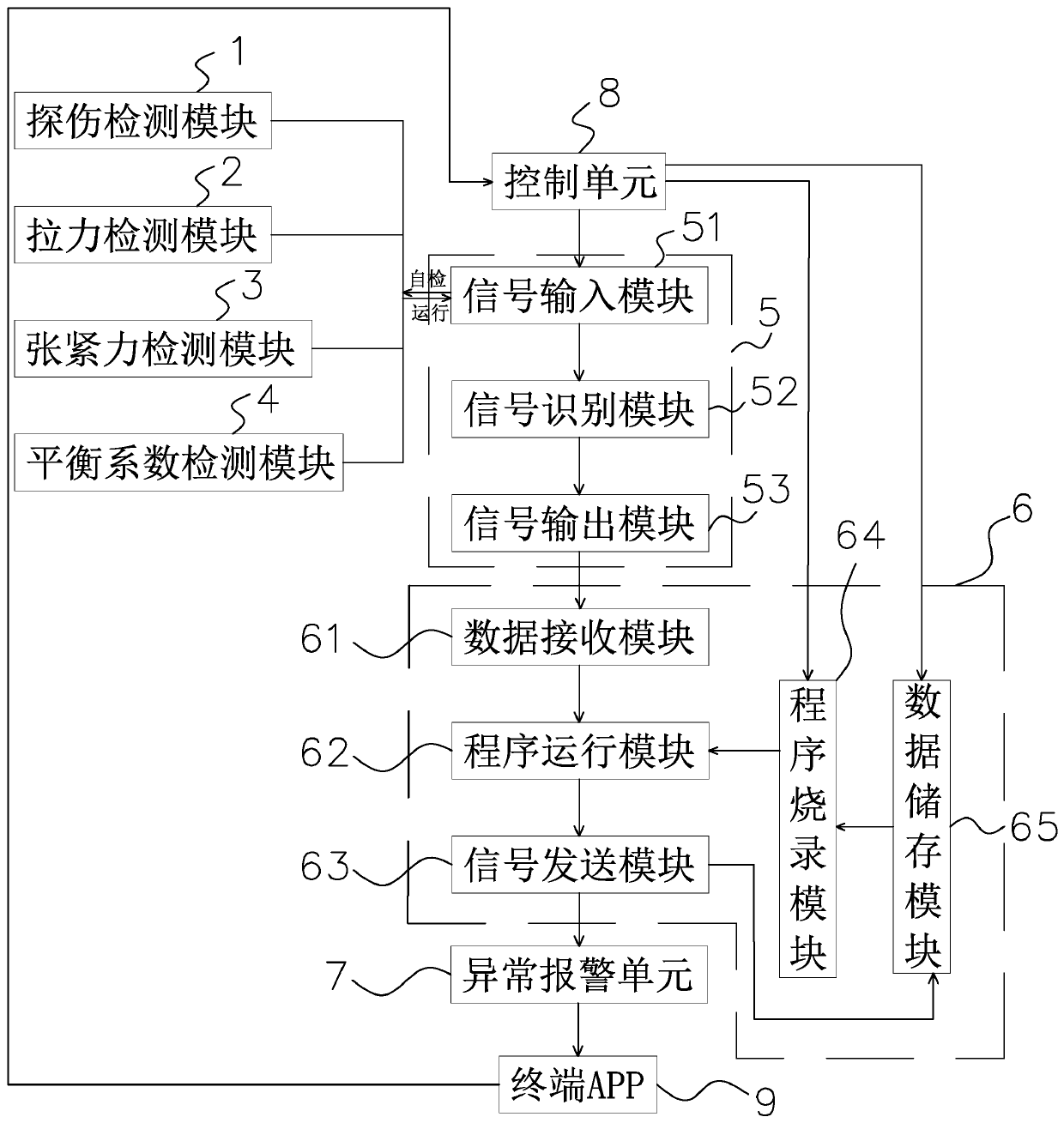

[0029] This embodiment discloses a wire rope monitoring device applied to an active safety elevator, including a flaw detection detection module 1, a tension detection module 2, a tension detection module 3, a balance coefficient detection module 4, an information collection unit 5, and an operation processing unit 6. Abnormal alarm unit 7, control unit 8;

[0030] The flaw detection module 1 is connected to the information collection unit 5, and the flaw detection module 1 is used to collect geometric image information of the elevator wire rope;

[0031] The tension detection module 2 is connected to the information collection unit 5, and the tension detection module 2 is used to detect the magnitude of the tensile force suffered by the elevator wire rope;

[0032] The tension detection module 3 is connected to the information collection unit 5, and the tension detection module 3 is used to detect the tension of each elevator wire rope;

[0033] The balance coefficient detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com