Full-closed fabricated stirrup with measurable overall length strain

A prefabricated, full-length technology, applied in the direction of measuring devices, instruments, structural elements, etc., can solve the adverse effects on the design accuracy and safety of reinforced concrete members, cannot ensure the effective restraint of the stirrups on the concrete, and cannot obtain the stirrup resistance. Contribution of shear bearing capacity and other issues to achieve the effect of ensuring readability, reducing errors, and ensuring constraint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

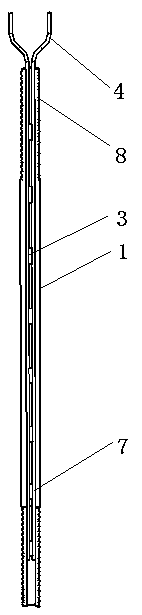

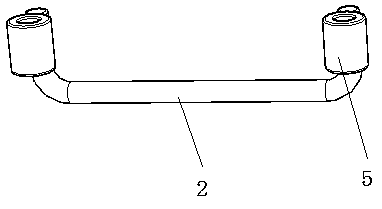

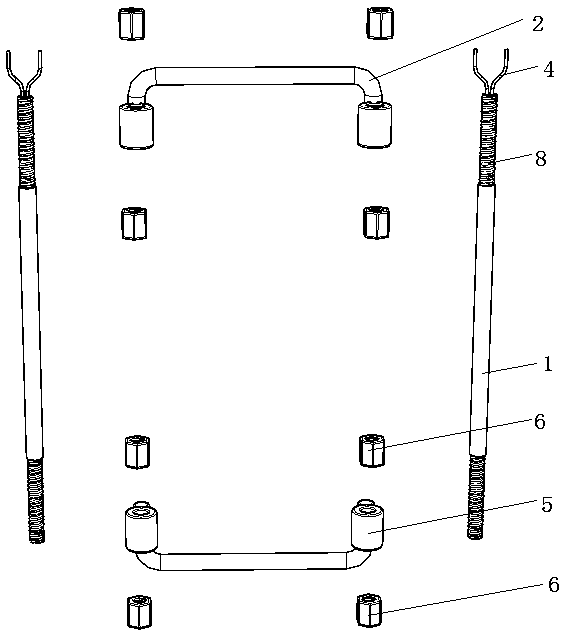

[0027] Such as figure 1 As shown, a fully closed assembled stirrup with measurable full-length strain in this embodiment includes two U-shaped steel bars 2 with the same structure, and a steel bushing 5 is welded to the free end of each of the U-shaped steel bars. , the steel bushings at both ends of the two U-shaped steel bars are respectively connected by a straight steel bar 1 to form a whole, and each straight steel bar is provided with a long straight groove 7 penetrating along its axial direction, so A group of strain gauges 3 are pasted at intervals on the inner wall of the long straight groove, and the strain gauges are connected by wires 4, and the wires protrude from the outside of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com