Structure for protecting bearing adopting bidirectional spiral grooves

A technology for protecting bearings and two-way spirals, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of high manufacturing and processing requirements, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0033] This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, components are exaggerated for clarity.

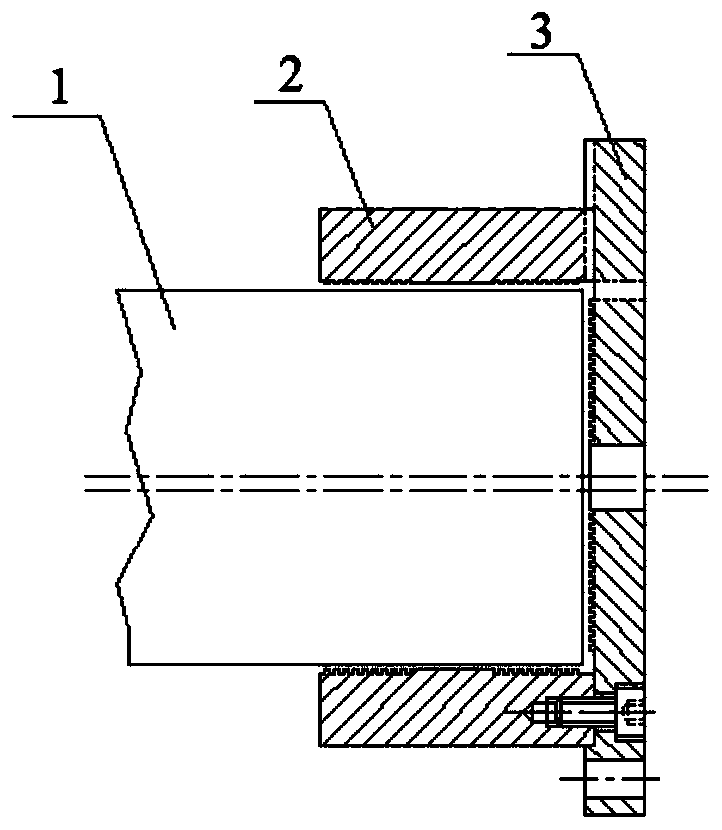

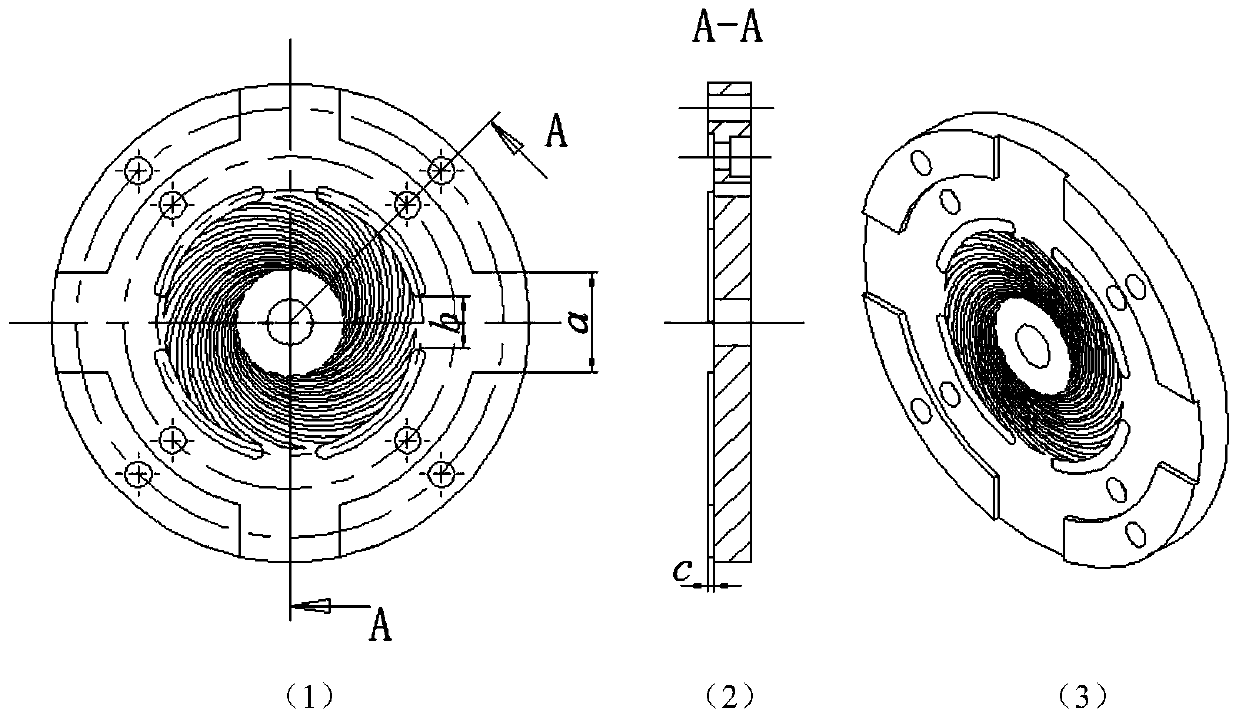

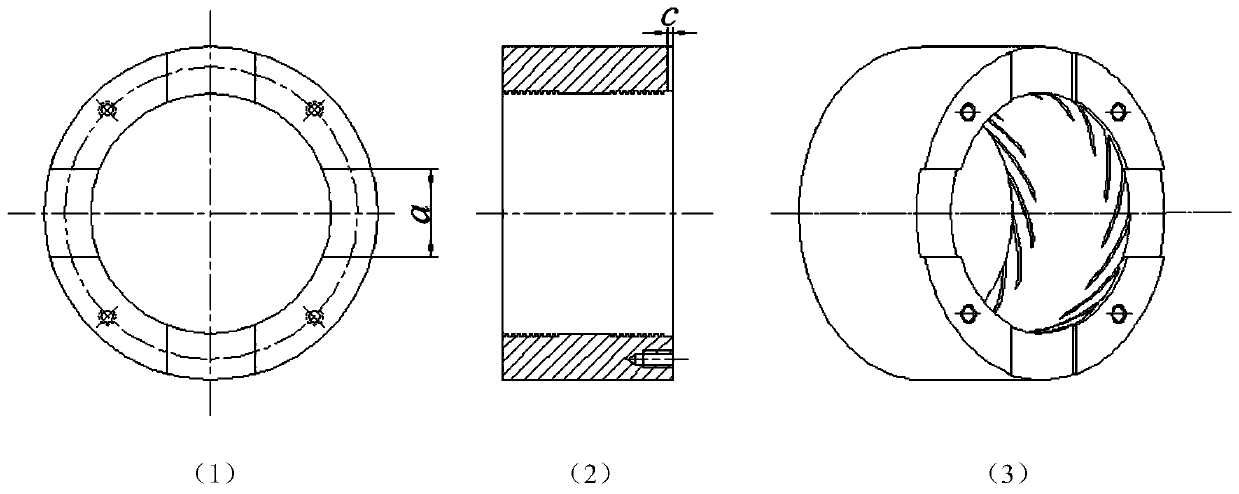

[0034] Such as figure 1 As shown, the present invention discloses a two-way spiral groove protection bearing, which includes a radial protection sleeve and an axial protection baffle;

[0035] The radial protection sleeve is a hollow tube with openings at both ends, so that the two ends are respectively end A and end B; the axial protection baffle is cylindrical, and the end faces on both sides are end face C, end face D .

[0036] Such as figure 1 , figure 2 As shown, the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com