Fully-automatic rice soaking equipment

A fully automatic rice soaking technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of easy dust entry, low work efficiency, high labor intensity, etc., to save work intensity , saving workload, reasonable equipment structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

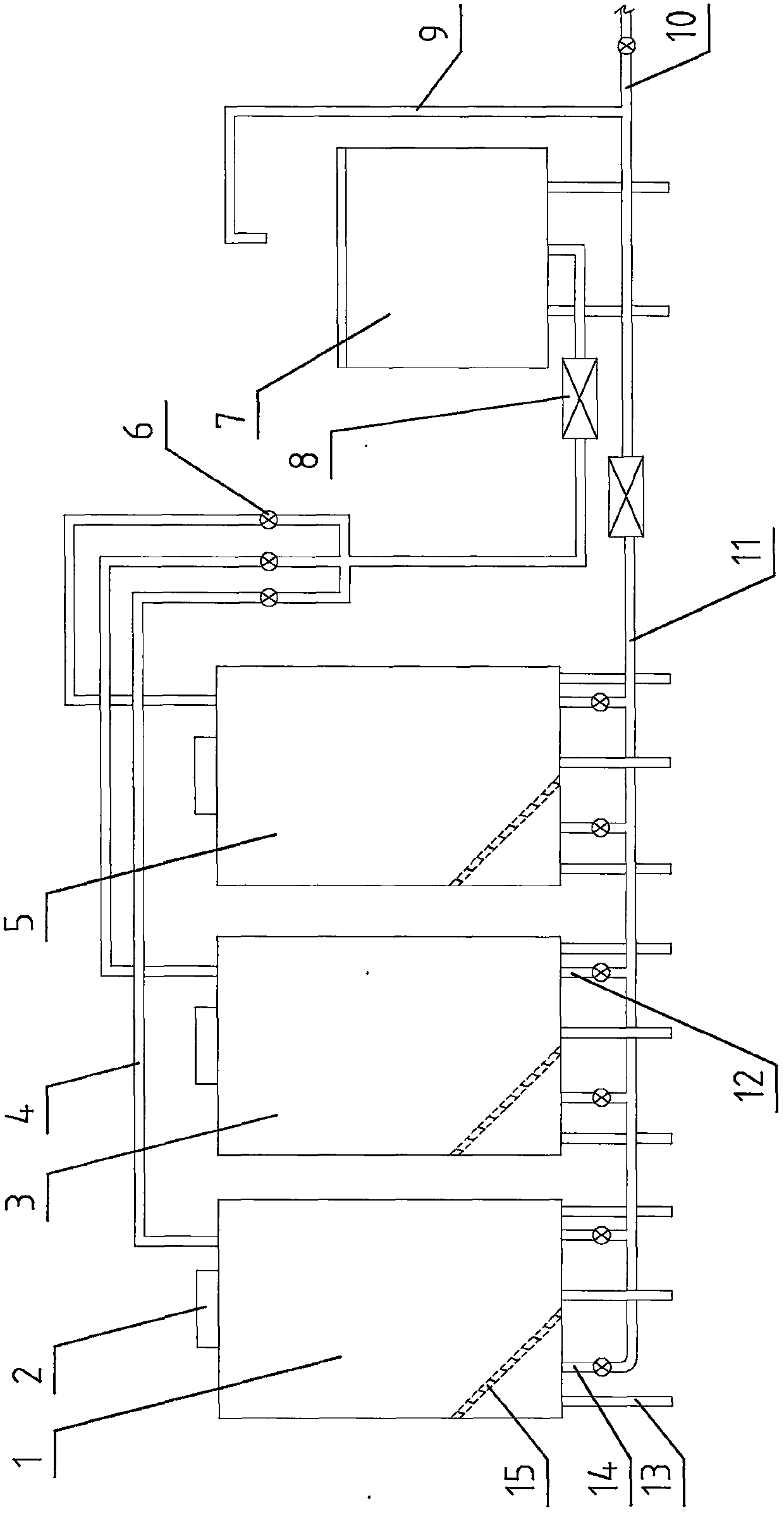

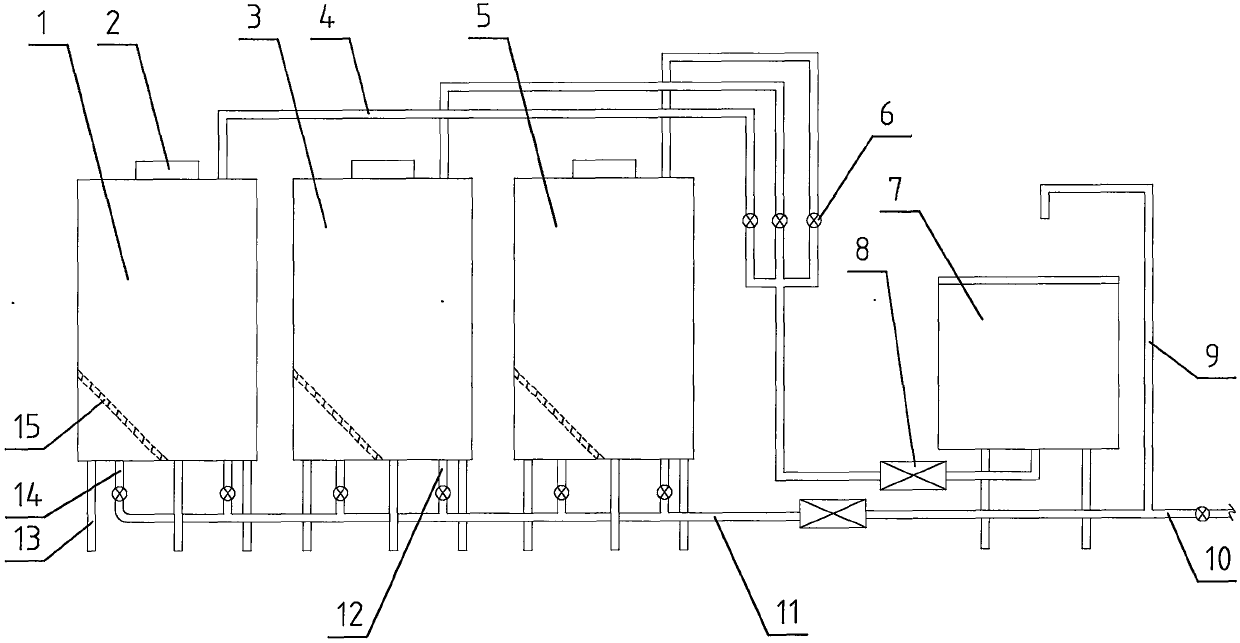

[0019] As shown in the figure, a fully automatic rice soaking equipment consists of a first rice soaking tank 1, a second rice soaking tank 3, a feed pipe 4, a third rice soaking tank 5, a valve 6, a feeding tank 7, a sanitary Pump 8, discharge pipe 9, drain pipe 10, main discharge pipe 11, discharge pipe 12, water outlet pipe 14, filter screen 15 parts.

[0020] As shown in the figure, the upper ends of the first soaked rice tank 1, the second soaked rice tank 3, and the third soaked rice tank 5 are all provided with an inspection port 2 and a feed pipe 4. The first soaked rice tank 1 and the second soaked rice tank 3. The lower end of the third soaking rice tank 5 is provided with a discharge pipe 12, a support frame 13, and a water outlet pipe 14. The first soaking rice tank 1, the second soaking rice tank 3, and the third soaking rice tank 5 are all provided with filter Net 15.

[0021] The three feeding pipes 4 are all provided with a valve 6, and the three feeding pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com