Metod and apparatus for continuously producing clouring polyester

A polymerization equipment and polyester technology, applied in the field of colored polyester manufacturing, can solve the problems of numerous procedures, environmental pollution, high cost, etc., and achieve the effects of uniform dispersion, easy operation and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

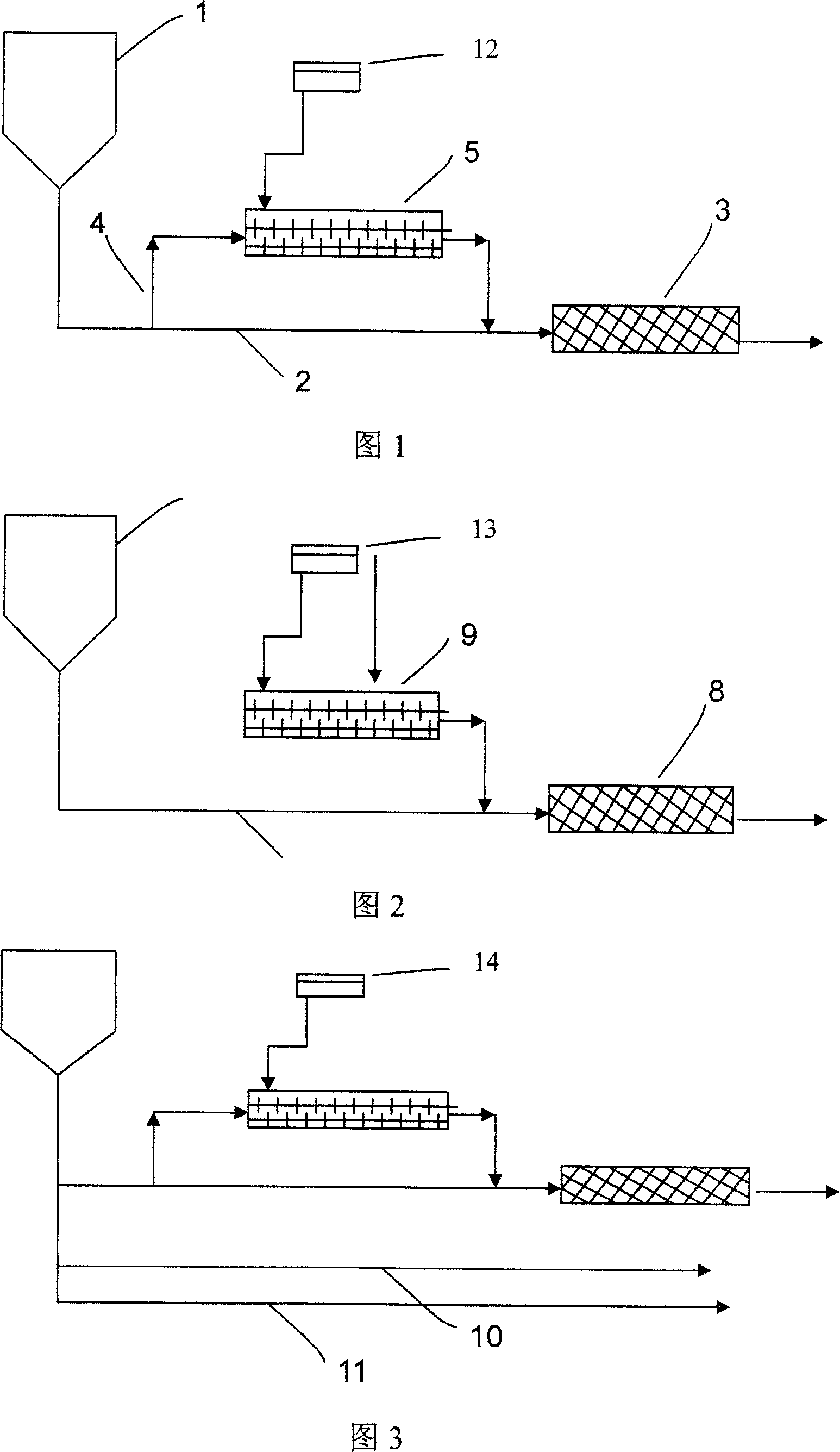

[0018] Use terephthalic acid and ethylene glycol as raw materials to carry out esterification reaction at 200-260°C, and then carry out recondensation reaction at 280-300°C under a vacuum lower than 300Pa to continuously produce poly(p-phenylene) with a viscosity of 0.655 Ethylene glycol diformate (abbreviated as: PET) melt. The polyethylene terephthalate melt in the continuous polymerization equipment 1 is input through the main pipeline 2 at a speed of 1000kg / h at a temperature of 220-320°C (for example, 220°C, 240°C, 280°C, 320°C). Co-mixing device 3, while branch pipe 4 inputs polyethylene terephthalate into screw kneader 5, and the supply rate is 5kg / h; cyan dye powder (functional particle) (or iron oxide red, medium chrome yellow , titanium dioxide or cobalt black, phthalocyanine green, toluidine purple dye) first add the dispersant polyethylene glycol (or trimethylolethane, metal stearate, polyvinylpyrrolidone, aluminum-titanium composite coupling agent) Pulverize and ...

Embodiment 2

[0019] Embodiment 2: preparation technology is the same as embodiment 1, and difference is that polyester feed rate and pigment consumption are different (see table 1) in the branch pipe, and the amount that contains cyan dye in the colored polyester of production is 4wt%.

Embodiment 3

[0020] Embodiment 3: preparation technology is the same as embodiment 1, and difference is that polyester feed rate and pigment consumption are different (see table 1) in the branch pipe, and the about 12wt% that contains the amount of cyan dye in the colored polyester of production

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com