Method and equipment for continuous production of antistatic polyester

A technology of antistatic and polymerization equipment, which is applied in the field of continuous production of antistatic polyester and equipment, can solve the problems of degraded blend quality deterioration, environmental impact, high cost, etc., and achieve low production costs, stable varieties, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

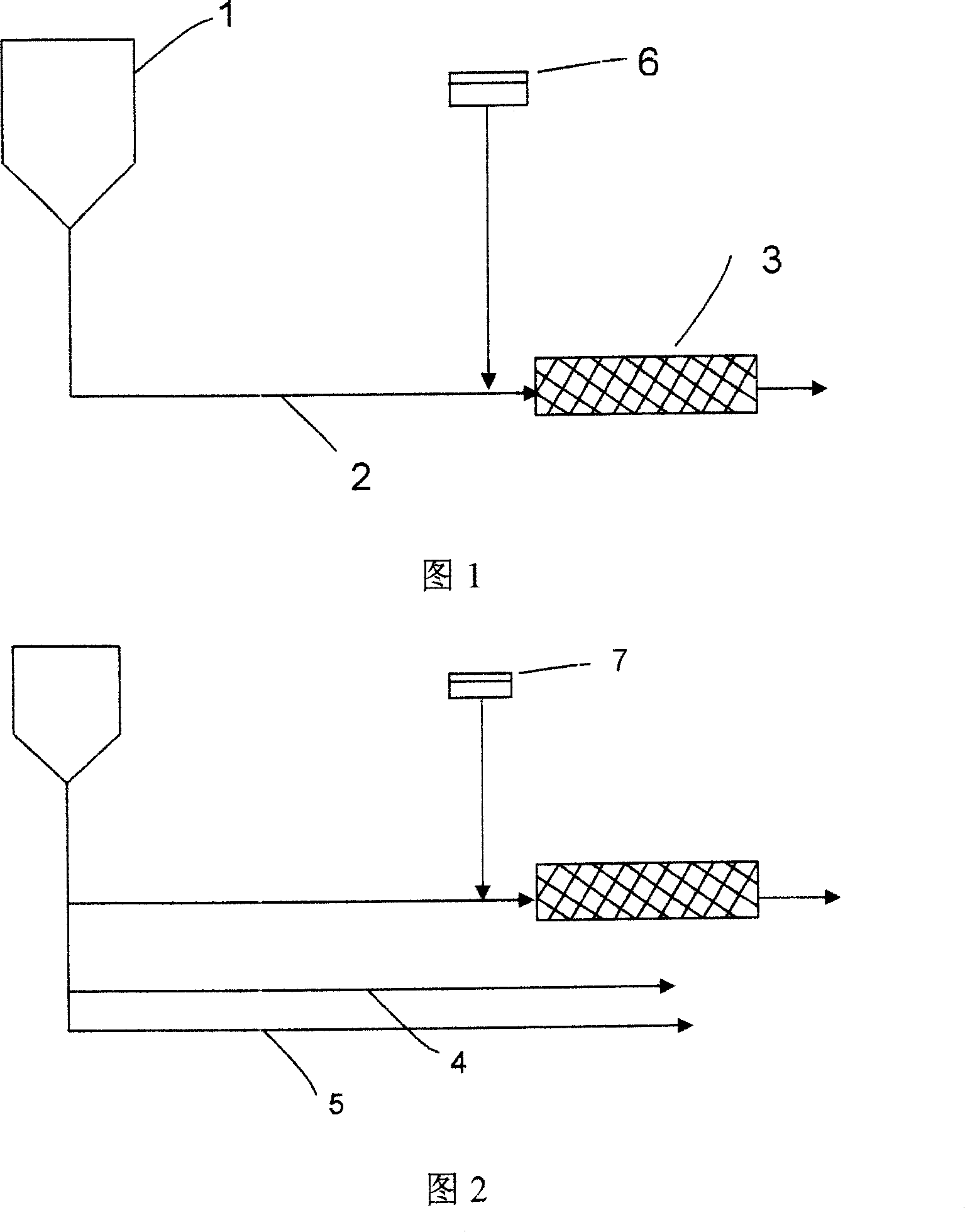

Embodiment 1

[0023] Use terephthalic acid and ethylene glycol as raw materials to carry out esterification reaction at 200-260°C (example 200°C, 230°C, 260°C), and then carry out esterification reaction at 280-300°C (example 280°C, 290°C, 300°C) ) temperature and lower than 300Pa vacuum to carry out recondensation reaction, and continuously produce polyethylene terephthalate (abbreviated as: PET) melt with a viscosity of 0.655. The polyethylene terephthalate melt in the continuous polymerization equipment 1 is input through the main pipeline 2 at a speed of 1000kg / h at a temperature of 220-300°C (for example, 220°C, 240°C, 280°C, 300°C). In the blending device 3, the antistatic masterbatch is added to the hopper 6, connected to the polyester main pipeline through a pipeline, and the supply rate is 5kg / h. The mixture further enters the blending device 3 for blending treatment to obtain antistatic polyester. The blending temperature in the blending device 3 was 280°C. The content of the an...

Embodiment 6

[0027] Use terephthalic acid and ethylene glycol as raw materials to carry out esterification reaction at 200-260°C (example 200°C, 230°C, 260°C), and then carry out esterification reaction at 280-300°C (example 280°C, 290°C, 300°C) ) temperature and lower than 300Pa vacuum to carry out recondensation reaction, and continuously produce polyethylene terephthalate (abbreviated as: PET) melt with a viscosity of 0.655. The polyethylene terephthalate melt in the continuous polymerization equipment 1 is input through the main pipeline 2 at a speed of 1000kg / h at a temperature of 220-300°C (for example, 220°C, 240°C, 280°C, 300°C). Co-mixing device 3; antistatic masterbatch and antioxidant IR1010 (or antioxidant 1076, antioxidant TNP, 168) are mixed and then added to the hopper 6, connected to the polyester main pipeline through a pipeline, and the supply rate is 5kg / h. The mixture further enters the blending device 3 for blending treatment to obtain antistatic polyester. The blen...

Embodiment 7

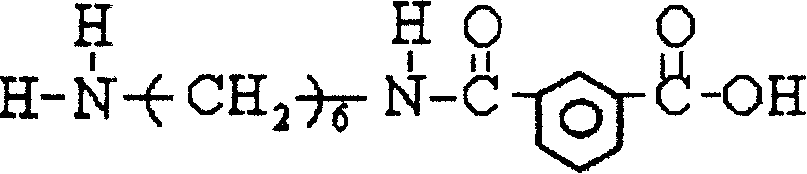

[0029] The polyester melt synthesized in the polymerization equipment is polyethylene terephthalate or polybutylene terephthalate or polypropylene terephthalate; polyester, antistatic masterbatch two The amount of raw materials for each component is calculated by weight percentage: polyester 97% to 99.5% (97%, 98%, 99.5%), antistatic masterbatch 0.5% to 3% (3%, 2%, 0.5%) ). Excess polyester output pipes 4 and 5 are connected to the main pipe in the equipment, and the rest are the same as in embodiment 1. Hopper 7 is arranged among the figure. The excess polyester that is shunted out can be directly used for spinning, film-forming processing or making polyester chips.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com