A self-regulating dust collector

A dust collector and self-adjusting technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of poor dust removal effect and low utilization rate of dust collectors, and achieve the best effect of absorbing tiny dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

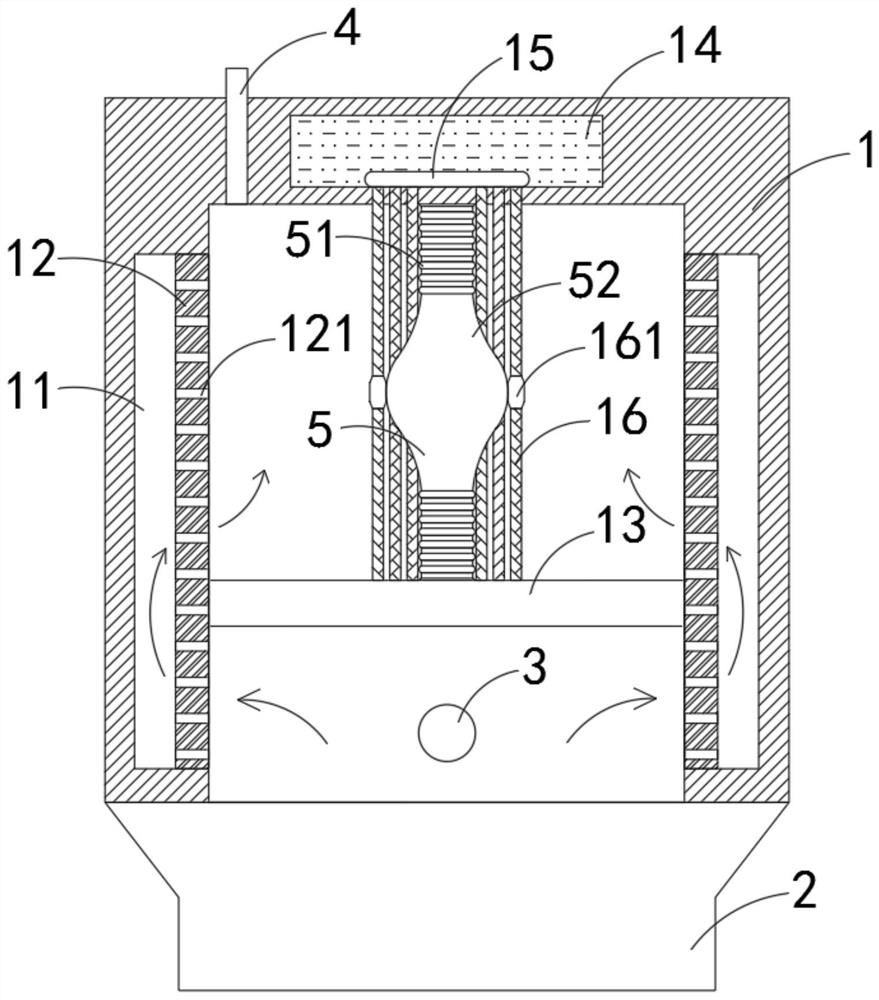

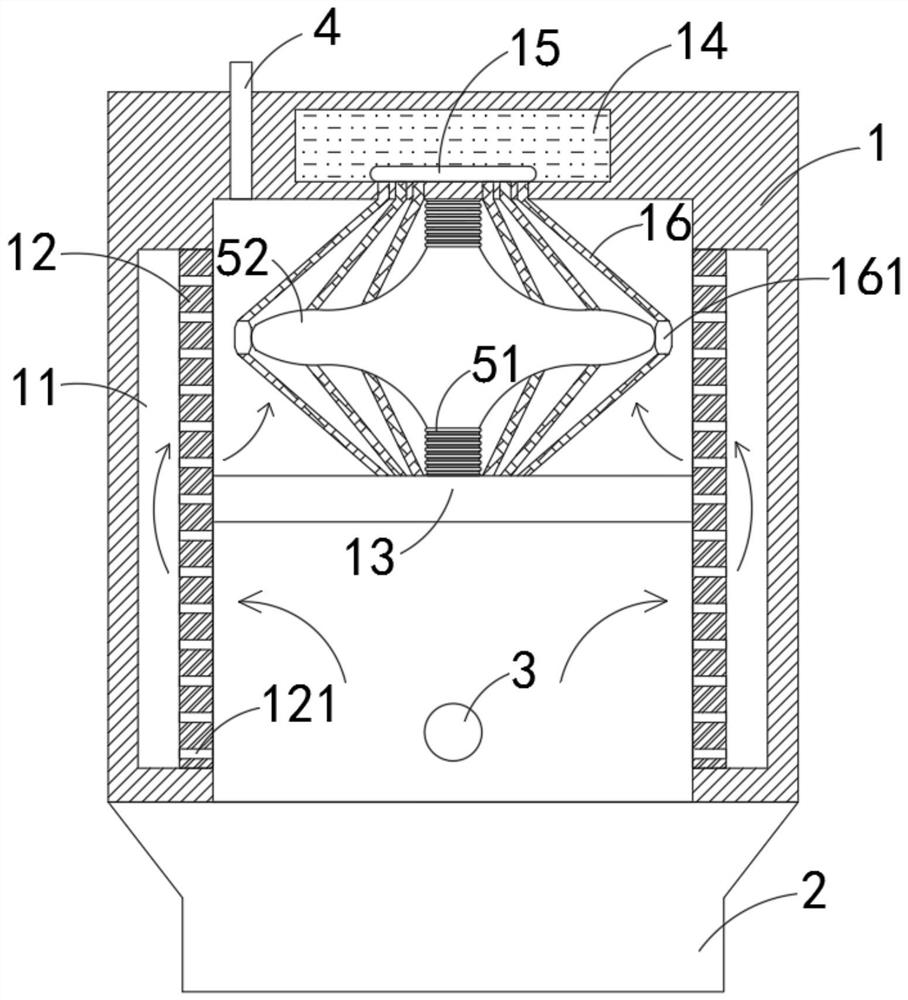

[0032] Such as Figure 1-2 As shown, a self-regulating dust collector includes a housing 1 and an ash hopper 2. An air intake pipe 3 and an exhaust pipe 4 are fixedly connected to the side wall of the housing 1. It should be noted that the air intake pipe 3 is close to the ash hopper 2, the exhaust pipe 4 is set on the top of the housing 1, and the housing 1 is equipped with:

[0033] Annular groove 11, the annular groove 11 is arranged on the inner side wall of the housing 1; dust filter plate 12, the dust filter plate 12 is fixedly installed in the annular groove 11, there is a gap between the dust filter plate 12 and the annular groove 11, and the array distribution on the dust filter plate 12 There are a plurality of dust filter holes 121; a sealing plate 13, and the edge of the sealing plate 13 is in sliding and sealing connection with the side wall of the dust filter plate 12; After the body 1, the large particles of smoke will directly settle into the ash hopper 2.

...

Embodiment 2

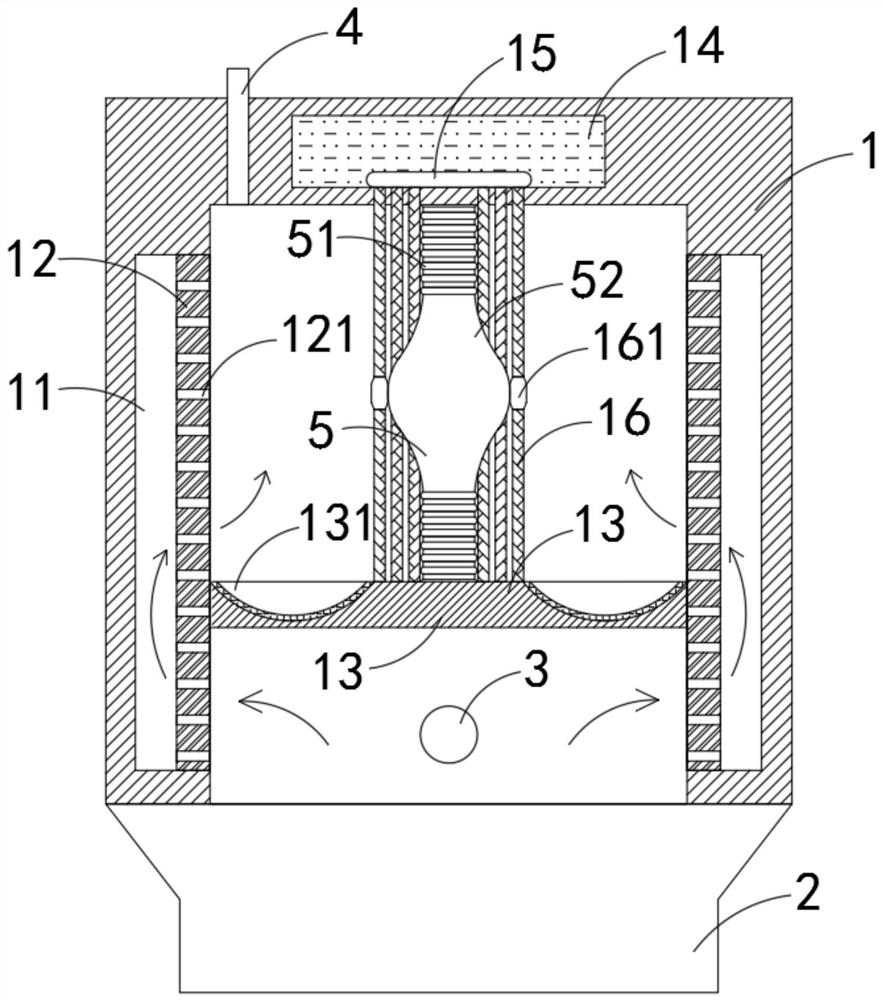

[0042] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the sealing plate 13 is made of a denser material such as a metal material, and the upper end of the sealing plate 13 is provided with a dust removal groove 131, and the dust removal groove 131 is a 52 is provided with an annular groove, and an adsorption layer is arranged in the dust removal groove 131.

[0043] In this embodiment, after the dust is filtered, the sealing plate 13 will fall vertically under the action of its own gravity and make the water-absorbing strip 16 straighten instantly, thereby throwing off the small water droplets adsorbed on the water-absorbing strip 16 Into the dust removal groove 131, it can facilitate the later cleaning, and can also improve the water absorption capacity of the water absorption strip 16, thereby enhancing the dust removal effect of the dust collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com